Our customer, who we are unfortunately not allowed to name here, specializes in plastics technology in the civil engineering industry. The company wanted to find out to what extent it is possible to use additive manufacturing (AM) profitably in its own company and on its products. The company had previously had no contact with 3D printing technology and its processes.

The goals

- Potential analysis

- Developing application concepts

- 3D printing system selection

- Production tests

- Material formulation

Challenges

- The components in question were larger than the standard 3D printing systems on the market are capable of printing.

- The diameter of these components was over 1.2m.

- The development team had no knowledge of CAD design for AM.

- The main material used was not 3D printable.

The solution

YIZUMI Germany

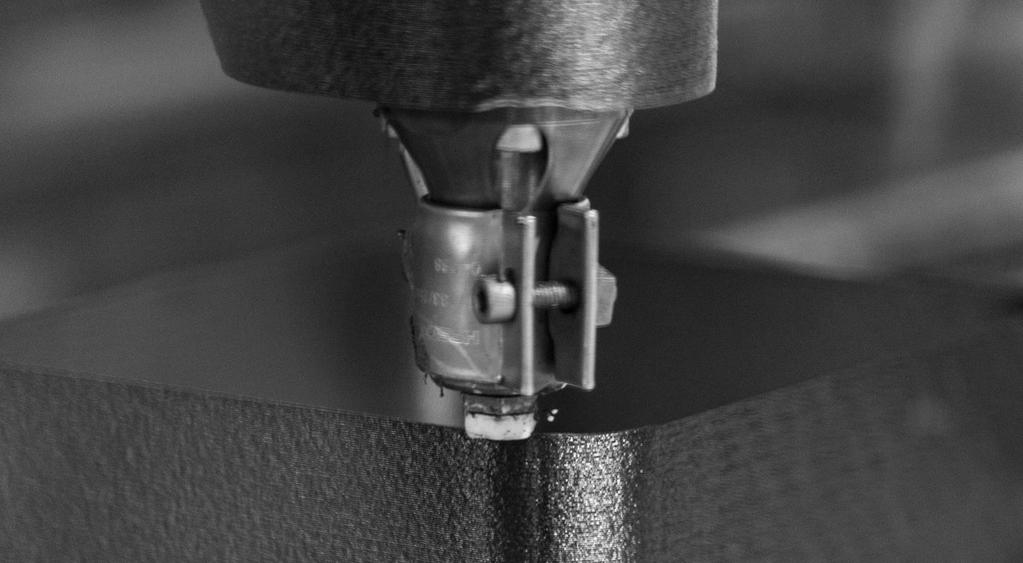

Extruder system on industrial robots

The 3D printing of large objects not only requires a large 3D system, but also a corresponding material throughput, which can only be achieved with so-called extrusion systems with pellet feed. After the evaluation and test phase, the decision was made in favor of the Space A system from YIZUMI Germany.

Material formulation by our material partners

The main material used by the customer is not 3D printable in its basic form and a new compound had to be developed. Thanks to our extensive and strong partner network, a customer-specific material was developed, tested and approved in a short space of time.

Training

To ensure that everyone involved, from construction to post-processing, understood, internalized and applied the processes, training sessions were held with the departments concerned.

The advantages

Technology leadership

Our customer is now a pioneer in manufacturing technology in its field of business.

24/7 production

Production does not stand still outside of working hours.

Time and cost savings

Reduction in man-hours and costs per component were cut by more than half in both areas

Offcuts and waste

The switch from a subtractive to an additive manufacturing process has resulted in a dramatic reduction in waste and offcuts. The waste can be shredded and added back into the production cycle.

Would you also like to benefit?

CONTACT

Our experts will be happy to help you. Get in touch with us!