SPATIAL VISION FOR EXCITING APPLICATIONS

The role of 3D cameras in industrial image processing cannot be overestimated. They enable precise, three-dimensional detection of objects, which significantly improves quality control and automation in production lines. By adding an extra dimension over conventional 2D systems, they open up new possibilities for a wide range of applications, from robotics to warehouse management. With their potential to transform industrial processes, 3D cameras are at the forefront of technological innovation.

Reto Moser from CHROMOS Industrial shows the Blaze 3D camera from Basler

Laser triangulation

Laser triangulation 3D cameras work by using laser technology to create accurate three-dimensional models. They emit a laser beam that is reflected by the object. By capturing these reflected points and calculating the exact position of each point based on the known angle and distance, highly accurate 3D images are created. This technology offers remarkable accuracy and speed.

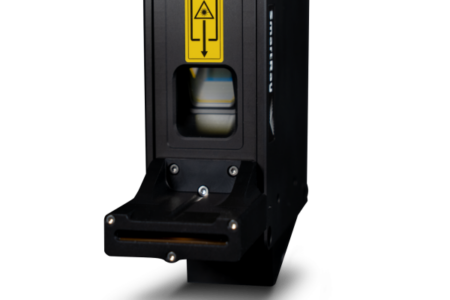

SmartRay Dual-Head ECCO 95+

The Dual-Head ECCO 95+ from Smartray is a powerful 3D sensor that enables shadow-free 3D scanning through the use of two cameras. This configuration ensures optimal visibility of the target object and minimizes occlusions that can occur with conventional 3D scans.

SmartRay ECCO 95G

Capture precise 3D data of glass and reflective surfaces with the Smartray ECCO 95G. Impressive scan rate and optimized optics make it the perfect solution for demanding applications.

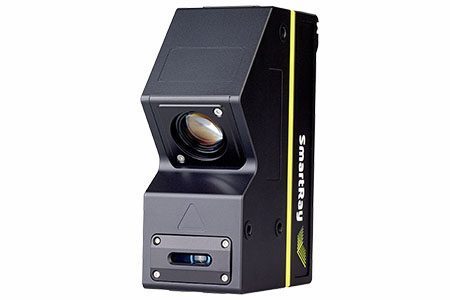

SmartRay ECCO 95+

The Ecco 95+'s combination of high resolution and fast measuring rate ensures efficient and accurate detection of complex geometries

SmartRay ECCO 85+

The SmartRay ECCO 85+ is the ideal solution for companies that require high image quality and value for money.

SmartRay ECCO X

With an impressive resolution of 4096 points and a fast scan rate of up to 40 kHz, this sensor offers precise and fast measurement results.

Time-of-flight

Time-of-flight (ToF) 3D cameras are advanced sensors that measure the time it takes light to travel from the camera to an object and back to create a depth map of the scene. They continuously emit pulses of light and measure the time it takes for the light to travel back and forth. This data is then used to calculate the distance between the camera and each point on the object, resulting in an accurate 3D image. ToF technology provides fast and accurate depth measurements, making it ideal for 3D modeling and mapping.

Stereo 3D

Stereo 3D cameras work on the principle of stereoscopy, which is similar to human eyes, to create three-dimensional images. They consist of two slightly offset camera lenses that capture two slightly different images of the same object, similar to the way a person's two eyes see different perspectives. By combining these two images in a process called stereo correlation, they can calculate the depth information of each point in the image and create an accurate 3D model of the scene. Stereo 3D cameras offer high depth resolution and are particularly good in natural light environments.

Basler stereo camera

With their effortless plug-and-play integration, ruggedized design for industrial high performance and modular software features, these cameras open up new dimensions in real-time perception of the environment for robot-controlled tasks.

Chromasens 3D camera

High-resolution and precise, ideal for use in the watch finishing industry

CONTACT

Our experts will be happy to help you. Get in touch with us!