SLS 3D printer

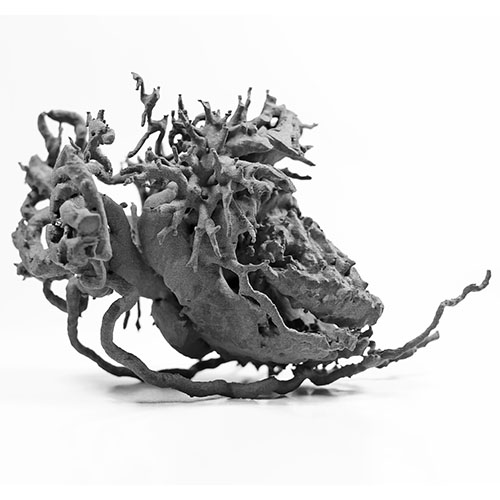

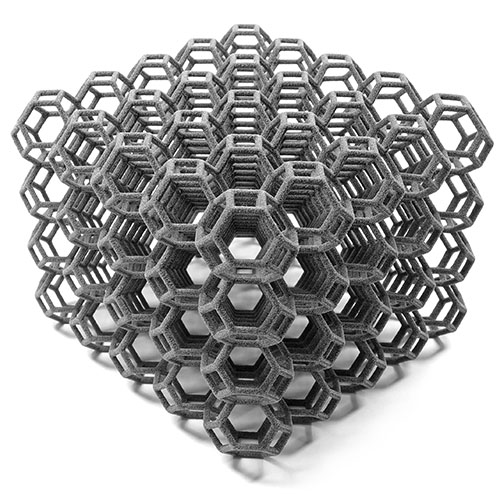

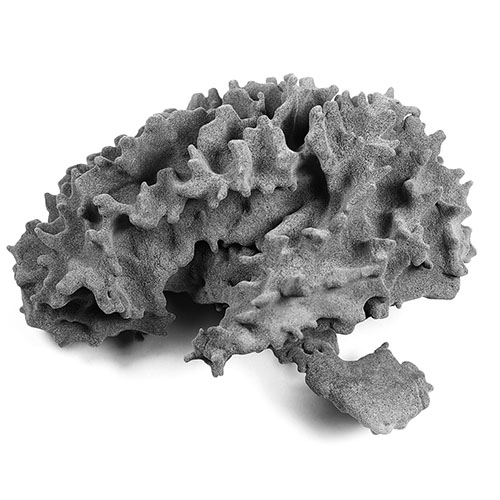

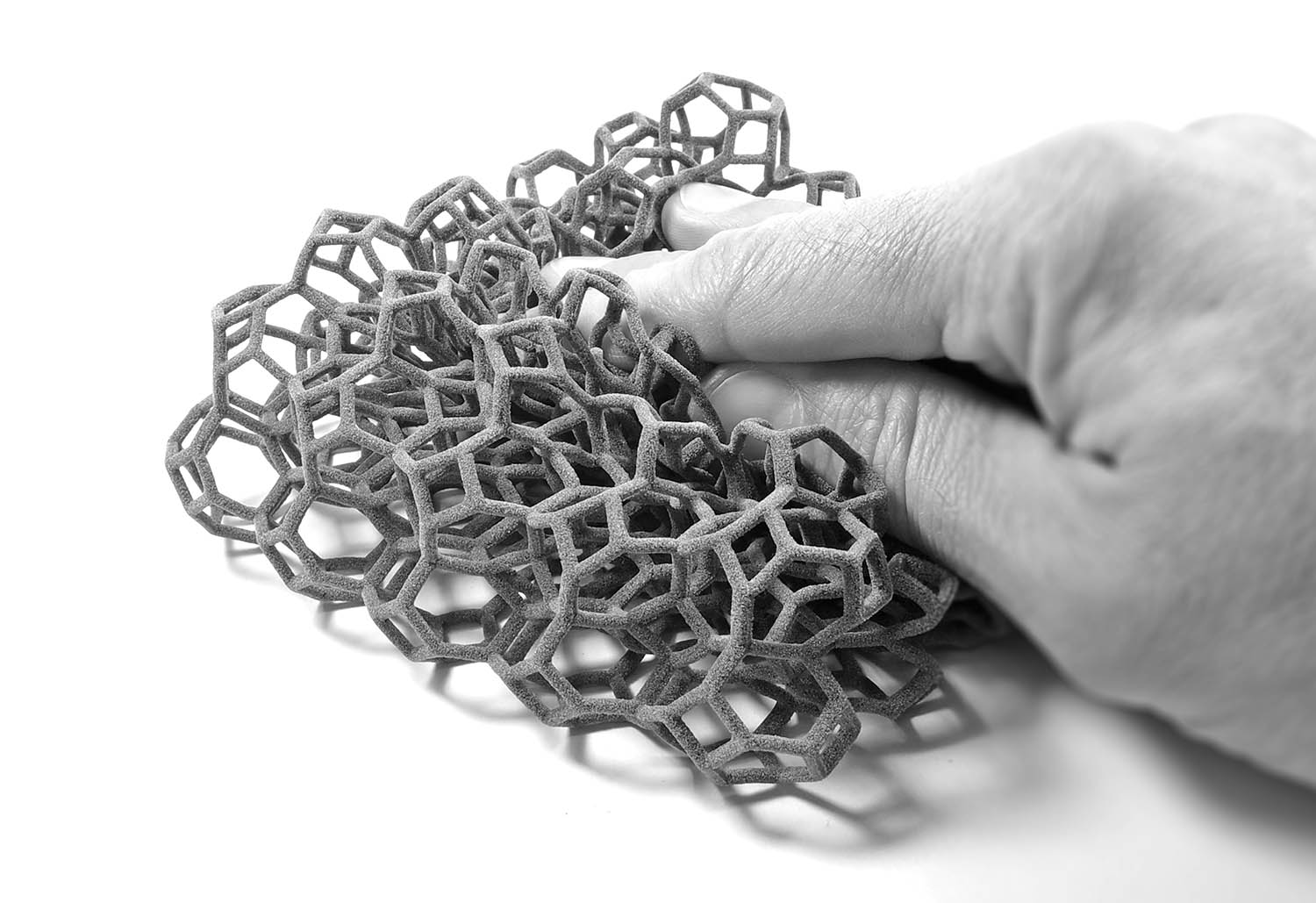

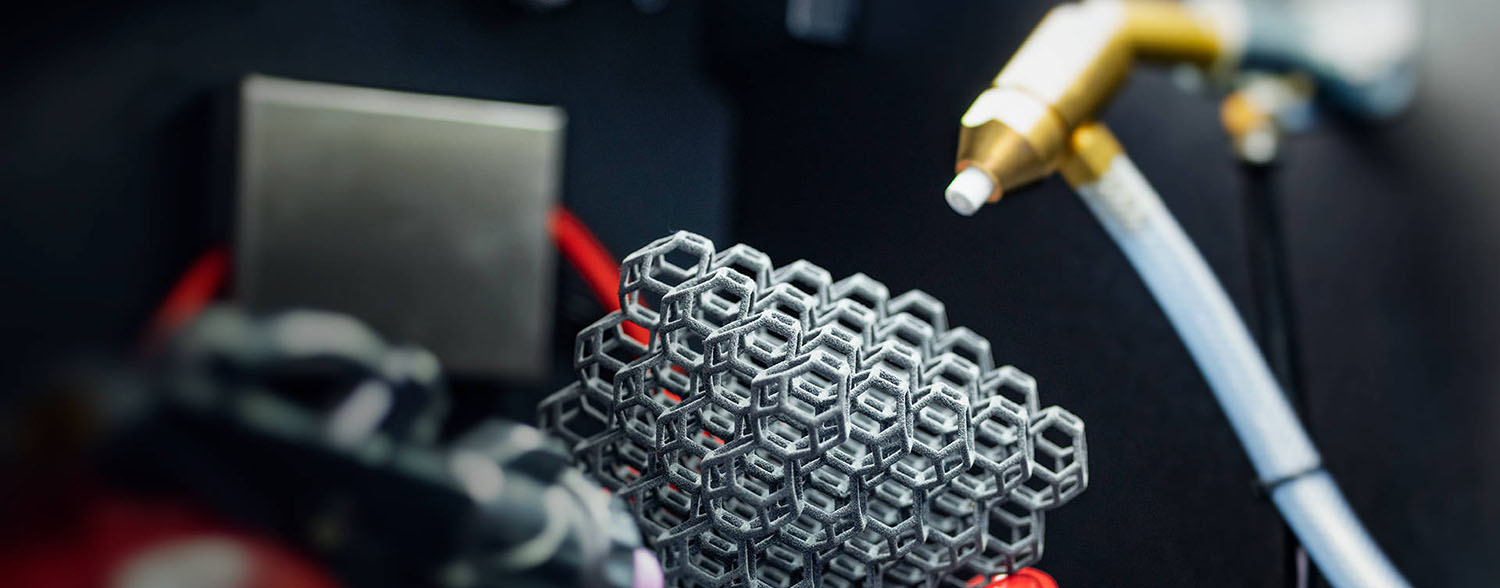

Detailed components, complex geometries and maximum material diversity - without support structures.

SLS stands for Selective Laser Sintering. In contrast to the SLA process, no liquid mass is hardened here, but polymer powder is fused in very fine layers. A major advantage of this technology is that no support structures are required.

SLS 3D printers are suitable for companies that want to manufacture customer-specific products or require functioning prototypes. With the excellent mechanical properties of the materials, ready-to-use finished parts can also be produced - whether for industry, product development or model making.

Get in touch with usSLS 3D printer from Sinterit

Sinterit offers powerful yet cost-effective SLS 3D printers that enable professional results. With the two models Lisa X and Suzy, Sinterit covers a broad spectrum - from rapid prototype development to small series production. While the Lisa X scores with maximum material diversity and flexible printing parameters, the Suzy impresses with its high printing speed and outstanding price-performance ratio.

Get in touch with us

Sinterit Suzy - Fast, efficient and inexpensive

Suzy is the entry-level solution for professional SLS printing - fast, cost-efficient and optimized for series production. With a printing speed of up to 20 mm/h and preconfigured material parameters, it offers an uncomplicated solution for a wide range of applications.

- Construction volume: 200 × 200 × 260 mm

- Print speed: Up to 20 mm/h - faster than most SLS systems

- Material compatibility: Optimized for PA12 Industrial

- Preconfigured parameters: Simple handling without the need for customization

- No nitrogen chamber: compact equipment for lower costs

Perfect for small series, functional prototypes and companies that value speed and efficiency.

from CHF 17'590.00

Find out more about Sinterit Suzy

Sinterit Lisa X - flexibility and material diversity

The Lisa X is the all-rounder in the SLS sector. With a large build volume and the ability to use a wide range of materials such as PA12, PA11, TPU, Flexa, ESD and CF, it is perfect for research, development and the production of complex prototypes.

- Construction volume: 245 × 245 × 300 mm

- Print speed: 10-14 mm/h

- Material compatibility: Wide selection of polymers and special materials

- Open print parameters: Freely programmable material settings for maximum flexibility

- Nitrogen chamber: Integrated for optimized material properties

Ideal for demanding applications that require maximum flexibility and material diversity.

from CHF 21'990.00

Find out more about Sinterit Lisa XWhat makes SLS 3D printers stand out?

No support structures required

SLS 3D printers build complex shapes freely in the build space - without any additional support materials. Instead, the component is stabilized by the surrounding powder during the entire printing process. This reduces post-processing, saves time and lowers material costs.

High resolution and precision

With layer thicknesses from 75 µm and an impressive level of detail, even the finest structures can be printed - ideal for prototypes, small series and complex geometries.

Wide choice of materials and sustainability

SLS 3D printers support a wide range of materials, including PA12, PA11, TPU and fiber-reinforced polyamide. Unmelted powder can be reused directly for the next printing process. This results in less material waste and keeps production costs low.

Challenges when using SLS 3D printers

The entry into SLS technology offers many advantages, but also brings with it specific challenges. From powder handling and the right infrastructure to converting from FDM or SLA - here is an overview of the most important points.

Cost-intensive purchase

The investment in an SLS 3D printer is usually higher than for FDM or SLA systems. In the long term, however, the costs are amortized through material savings and the robust design.

Powder handling and storage

Handling fine powder requires a clean environment and special storage. Residual powder can be recycled and reused.

Space requirements and infrastructure

An SLS 3D printer offers professional printing results, but also requires a well-equipped production environment. This includes secure storage areas and efficient material processing.

Conversion from FDM or SLA to SLS

Many entry-level printers are based on FDM or SLA technology. Switching to SLS requires a rethink in terms of material handling - but offers significantly more options and greater precision

Video: Understanding SLS 3D printing - using the Lisa X workflow as an example

How does selective laser sintering actually work in practice? In this video, you will see step by step what a complete SLS printing process looks like - from file upload and printing to powder recovery and post-processing.

The process is demonstrated using the Lisa X system, including cleaning and material preparation. You will gain a realistic insight into:

- How an SLS printer works

- Handling powder and components

- The most important steps for a clean, efficient workflow

- Options for material recovery and process reliability

Ideal for anyone who wants to get to know and better understand the SLS process.

Post-processing & accessories - clean results, efficiently implemented

After printing, the component is embedded in the powder bed. To be able to use it, the excess powder must be removed - coarse and fine.

The complete SLS workflow also includes sieving the powder, cleaning the machine and recovering and reusing the material. These steps not only ensure print quality, but also reduce material costs.

In many cases, this is followed by a sandblasting process that removes loose particles and ensures clean, dimensionally stable surfaces.

SLS accessories - For a smooth workflow after printing

From powder handling to surface finishing: for professional SLS printing, it's not enough to just have a good device - the accessories also need to be right.

With the right setup, you can ensure clean processes, less material loss and consistently high component quality. The right components for printing, cleaning and powder management make all the difference.

Available as an accessory:

- Powder handling station - powder recovery and preparation

- Powder sieve - For optimum recycling

- Vacuum cleaner (ATEX-certified) - safety when vacuuming and cleaning

- Tool set - For safe and clean handling of the printed parts

- Sandblaster - For finishing and improving the surface quality

- Machine frame - For more order and flexibility in the working environment

- Print preparation software - For seamless operation and job management

Ideal for anyone who wants to map their SLS printing process professionally and economically.

To the SLS accessories area

The CHROMOS way to the optimum solution

Understanding requirements

We analyze your requirements precisely - from the desired component size to material properties and throughput. We also include the production environment in the planning.

Propose technology and solution

Based on the analysis, we select the right 3D printing technology and the optimal device. We plan the entire process together - including material selection and post-processing.

Test feasibility

Our technicians will set up your 3D printer and ensure optimal configuration. We offer training for your team on request.

Integration and support

We are also there for you after the purchase - with reliable support, material replenishment and technical assistance.

Our tip: Get advice from our experts

Not every 3D printer is suitable for every application - and not every printing technology is ideal for all materials, component sizes or production requirements.

We help you to find the perfect solution for your projects - precise, efficient and optimally tailored to your requirements.

Contact us

Our experts will be happy to help you. Get in touch with us!