Automatic labeling of packaging

Automated labeling solutions for products, cartons and pallets - integrated quickly, precisely and reliably.

Labeling is a crucial step in industrial marking - whether for product identification, traceability or logistics. Different labeling solutions are used depending on the type of packaging and requirements: from compact systems for individual product labeling to fully automated print & apply solutions for shipping cartons and pallets.

CHROMOS offers tried-and-tested solutions for every packaging level - tailored to line speed, label format and integration requirements. Our systems ensure clean, reliable and process-safe labeling - without any manual intervention.

Get in touch with usWhy is automated labeling important?

Enabling traceability

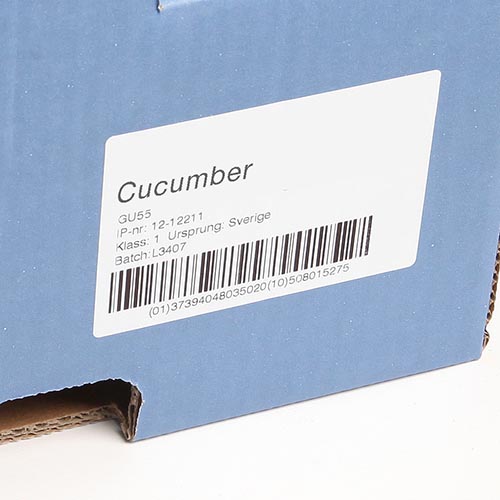

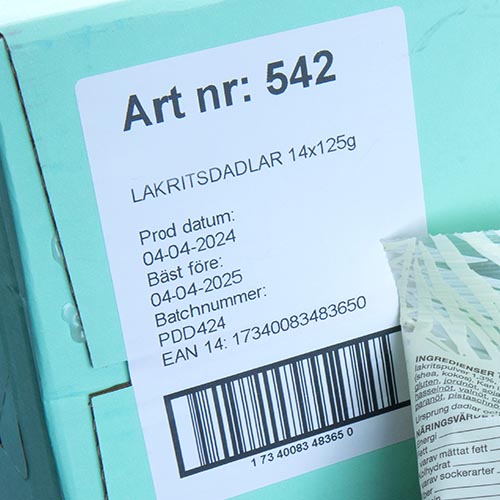

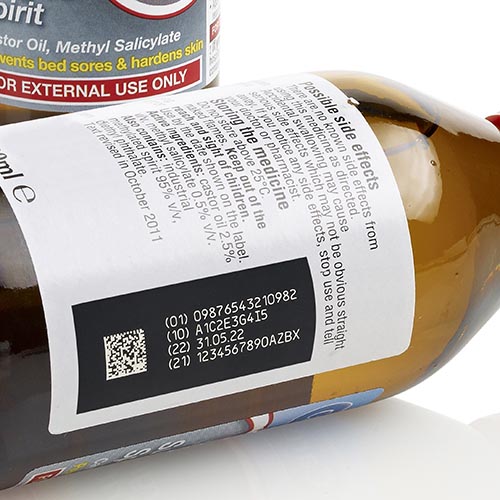

Labels with batch or serial numbers, manufacturing information or GS1-compliant codes are essential for seamless traceability along the supply chain - especially in regulated industries such as pharmaceuticals, food or medtech.

Automate logistics

In shipping, warehousing and e-commerce, automatic labeling ensures efficient material flows, clear allocation and error-free shipping processes. A flexible solution is particularly important for changing products or formats.

Labeling products

Labels convey important information such as ingredients, consumption data or usage instructions - clearly legible and precisely positioned, even at high cycle rates. Depending on the application, they can also be used for branding or legal labeling requirements.

Challenges in the automated labeling of packaging

Automatic labeling has specific requirements depending on the type of packaging and line. Three aspects are particularly crucial:

Positioning & format diversity

Packaging varies in size, shape and material. To ensure that labels are placed precisely, systems with high application accuracy are required - even with changing product formats or irregular surfaces.

Label adhesion & material compatibility

The labels must adhere securely - regardless of whether they are made of cardboard, plastic or shrink film. The choice of material is crucial for process reliability, especially on damp, dusty or cool surfaces.

Cycle time, line integration & data generation

Labeling systems must fit the line - in terms of cycle speed, space and system connection. Variable data such as serial numbers or shipping information must also be automatically generated and reliably transferred to the system.

Systematic labeling: Print & Apply in action

Print & apply systems are primarily used for automatic labeling in industrial packaging. These systems print labels in real time and apply them precisely to products, cartons or pallets - even with changing formats or high cycle rates.

Which solution is best suited in detail depends, among other things, on the packaging level, the label type and the requirements for data connection, integration and application accuracy.

Get in touch with us

Product labeling

Compact labelers apply smaller labels precisely to individual products - e.g. cosmetics, food supplements or foodstuffs. Pre-printed labels can also be applied reliably.

- Suitable for bottles, bags or folding boxes

- Space-saving integration into existing lines

- Precise positioning even at high cycle rates

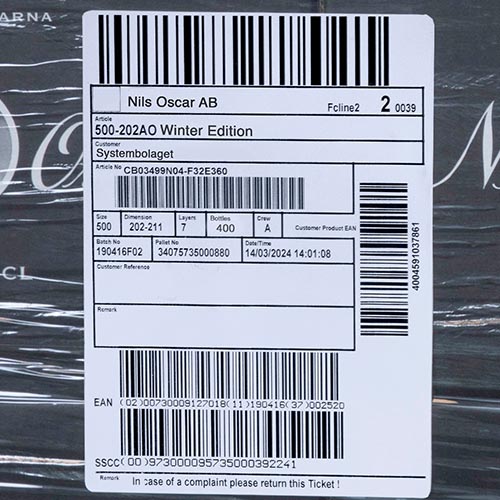

Shipping and logistics labels

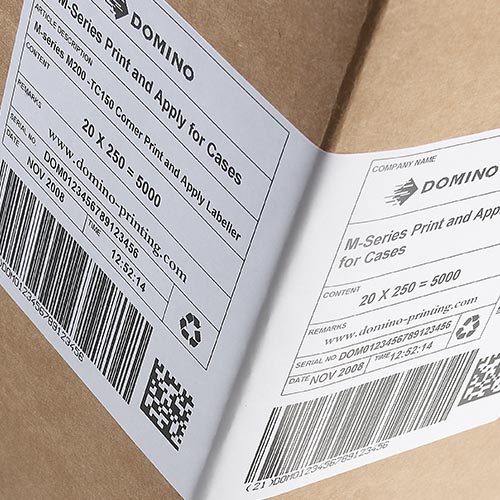

Print & Apply systems print shipping information, SSCC codes or customer-specific content in real time and automatically apply them to trays, shipping cartons or outer packaging.

- Automatic data transfer from ERP or WMS

- Flexible with changing formats and content

- Particularly robust and low-maintenance in logistics operations

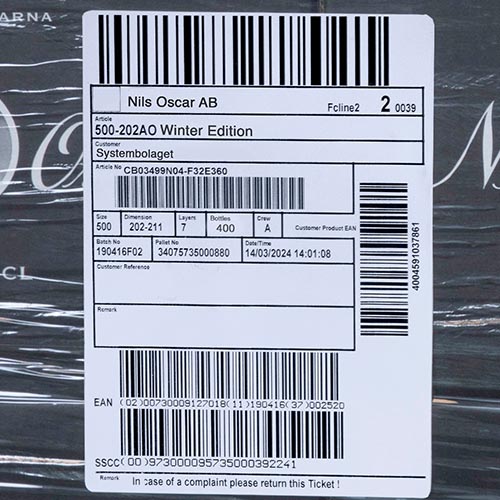

Pallet labeling

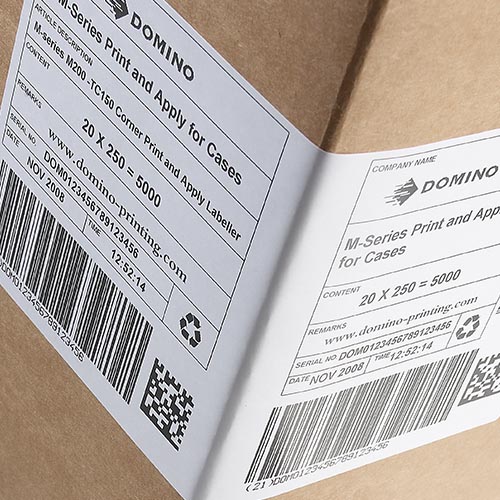

The Domino Mx series offers special application solutions for pallets - e.g. with a corner wrap module for double-sided labeling in a single step. Ideal for traceability in the shipping process.

- GS1-compliant labels for pallet labeling

- 1 or 2-sided application

- Safe, forklift-compatible positioning even in harsh environments

The CHROMOS way to the optimum solution

Understanding the application

Whether individual product, shipping carton or pallet unit: together we analyze your production conditions, the desired label content and requirements for positioning, legibility and process integration.

Suggest technology and implementation

Based on your application, we will show you suitable Print & Apply solutions and specific implementation options - tailored to line speed, label type, packaging level and system environment.

Check feasibility

We validate adhesion, positioning and data transfer in practical trials - and ensure that the solution can be stably integrated into your existing infrastructure.

Support through to commissioning

From device selection to system integration and training - our team will accompany you with technical expertise and reliable support.

Our tip: Get advice from our experts

Labeling is more than just applying information - and every line has different requirements in terms of technology, data handling and integration.

We support you in finding the optimum solution for your products, shipping cartons or pallets - reliable, automated and tailored to your production environment.

Use case: Shipping labeling at Jollyroom

The Nordic online retailer Jollyroom relies on an automated print & apply system from Domino for labeling its shipping boxes. Thousands of parcels leave the warehouse every day - high speed, error-free data and reliable labeling are essential.

With the Domino M series labeling solutions, shipping labels are printed directly on the line and applied precisely to the cartons. The systems are fully integrated into the existing warehouse management system and enable an end-to-end automated process - fast, stable and low-maintenance.

"The system simply works - it is stable, low-maintenance and saves time."

- Jollyroom Logistics Manager

Technology: Domino M-Series Print & Apply

Packaging type: Shipping cartons / tertiary packaging

Special feature: Integration into automated conveyor line

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!