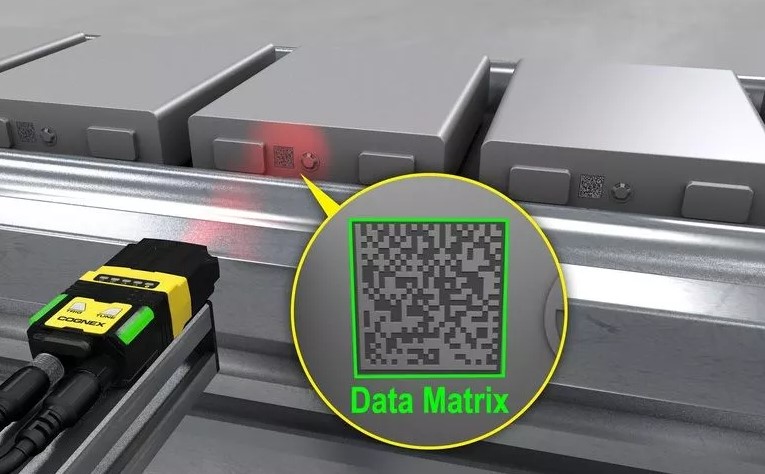

Barcode and 2D code inspection in production

Automated systems ensure the readability and correctness of codes - even at high speeds.

Today, 2D codes are a central component of industrial production and logistics processes. They contain information on traceability, shelf life or product identity and must be clearly legible in every situation. With automated verification, codes can be reliably checked - regardless of the material, surface or printing process. This minimizes sources of error, complies with legal requirements and ensures quality standards.

Get in touch with usWhy automated code verification is important

Ensure traceability: 2D codes are the foundation of modern supply chains. They carry important information such as batch numbers, production date or shelf life and make products clearly identifiable. Traceability across all process steps can only be guaranteed if these codes are reliably verified.

Guarantee quality and safety: A faulty or illegible code can have serious consequences: from production stoppages and recalls to damage to image. Automated checks detect even the smallest deviations in real time and ensure that only perfectly marked products are put into circulation.

Meet standards and regulations: Strict coding requirements apply in regulated industries such as pharmaceuticals, food and consumer goods. Automated verification systems check whether barcodes and 2D codes comply with the relevant standards, thus ensuring compliance with legal requirements and internal quality guidelines.

Challenges in automated code reading

The implementation of reliable dimension and shape control is challenging. Different materials, production speeds and environmental conditions place special demands on the systems used. Typical challenges are

Variety of materials and surfaces

Whether foil, cardboard, glass or metal - every surface influences the readability of codes. Lighting and image processing must be precisely matched to achieve reliable results.

High production speeds

In fast-paced lines, there is little time for recording and evaluation. Vision systems must record and check codes in real time without slowing down the production process.

Fluctuating print quality

Deviations in position, sharpness or contrast are part of everyday life. Systems must be robust enough to recognize such variations and still verify them without errors.

Suitable machine vision technologies

Maximum precision is required for dimensional and shape control. Machine vision systems must be able to measure reliably in the micrometer range and be robust against changing conditions. The following technologies have proven particularly effective:

Get in touch with us

Industrial cameras with external processing

These systems consist of a camera, optics and lighting that capture images and transmit them to an industrial PC for evaluation. They offer maximum flexibility, but require additional integration effort.

- Can be freely combined with various software and hardware components

- Very high image quality even with demanding codes

- Suitable for complex or combined tests

Smart cameras - all in one device

Smart cameras combine camera, processor and software in a compact housing. They reduce hardware requirements and can be quickly integrated into production lines.

- No external industrial PC required

- Easy to install and operate

- Ideal for standardized code reading tasks

Specialized code verifiers

Code verifiers specialize in checking barcodes and 2D codes. They evaluate readability and conformity to international standards, thereby ensuring process quality.

- Assessment according to ISO/IEC standards

- High reliability during quality audits

- Focus on code quality and compliance with standards

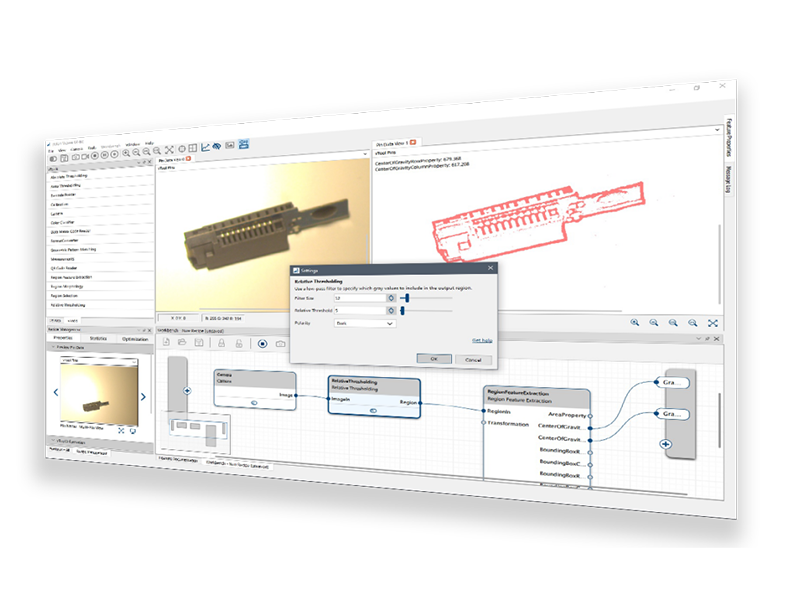

Software solutions - classic & deep learning

The software analyzes the code in real time. Depending on the application, rule-based procedures or deep learning methods are used.

- Rule-based: precise with stable processes

- Deep learning: robust with variable print quality

- Support for 1D and 2D codes and OCR/OCV

The CHROMOS way to the optimum solution

Requirements analysis and preliminary tests

We check the specific requirements of your codes - from materials and print quality to cycle times - and use test scenarios to show how reliable verification can be achieved.

Selecting the right system class

Whether a modular industrial camera, compact smart camera or specialized code verifier: we select the solution that best suits your process and standards.

Integration into the production line

Our systems can be seamlessly integrated. Results are transferred directly to control systems or databases and can be used for documentation and traceability.

Support during operation

We provide support during ongoing operation and with adaptations - with local service, support and training for your team.

Contact us

Our experts will be happy to help you. Get in touch with us!