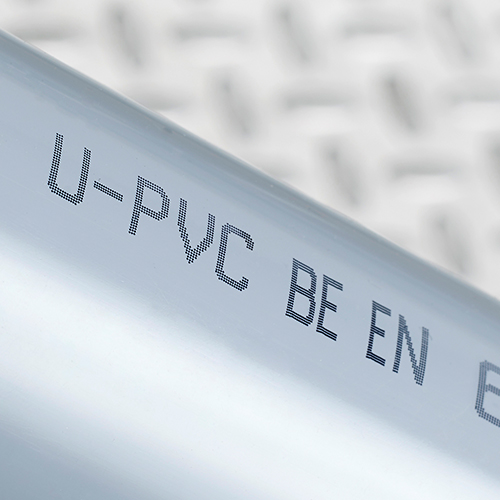

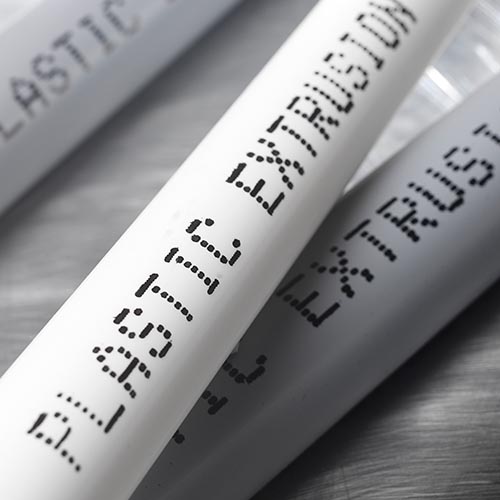

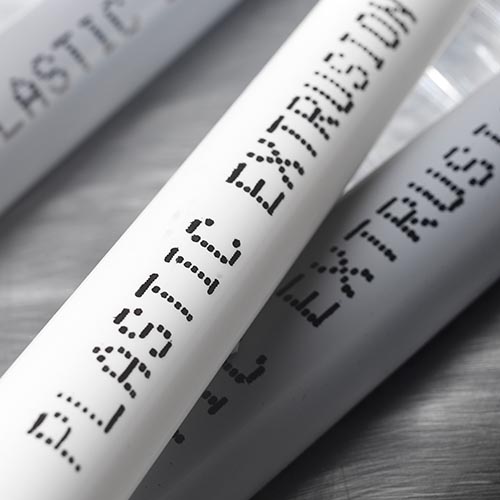

Label cables, pipes and other extrusion products

Reliable marking at high speeds - even on rotating, heat-resistant or difficult-to-print materials.

The marking of cables, pipes and extruded plastic profiles places special demands on technology and ink. The products are often round, flexible or are processed hot - at high line speeds and under demanding environmental conditions.

There are also special requirements in terms of adhesion, drying time and positioning, especially for rotating products. To ensure that texts, length markings or codes can be applied permanently and legibly, precisely coordinated systems are required - from the choice of ink to mechanical integration.

Get in touch with usWhy is the labeling of extrusion products important?

Product identification and traceability

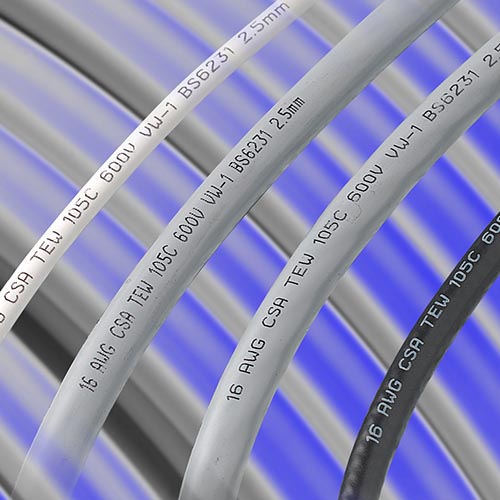

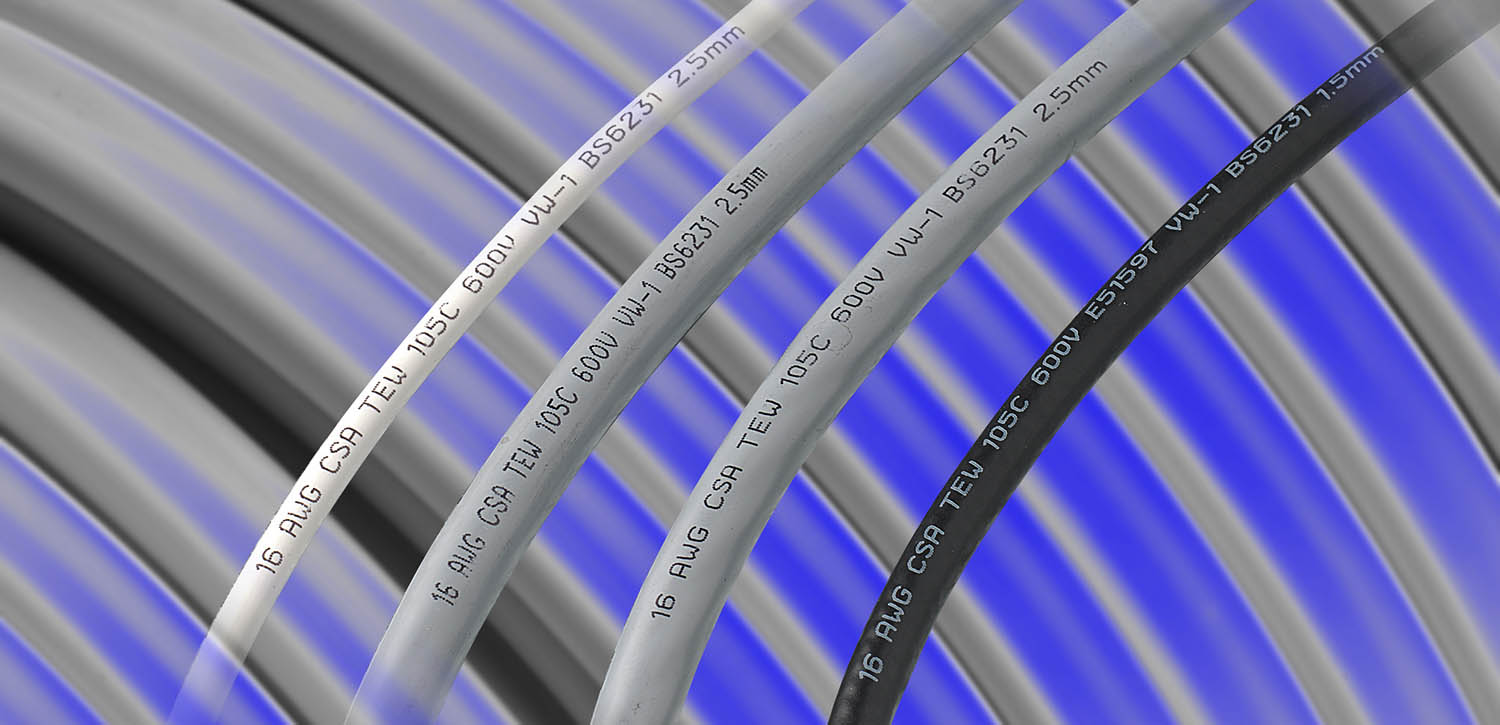

Manufacturer details, article numbers, serial codes or date stamps ensure clear identification - from production to the construction site or final assembly. This is particularly essential for safety-critical products such as energy cables or pressure pipes.

Length and positioning markings

Many cables and pipes are continuously marked with length specifications (e.g. every 1 m) or cut marks. These markings must be precisely positioned, permanently visible and precisely repeatable despite movement.

Comply with standards and industry specifications

In sectors such as construction, energy, automotive and medical technology, there are strict requirements for mandatory labeling and material documentation. The labeling must comply with these standards - both visually and in terms of content.

Challenges in the marking of cables, pipes and extrusion products

Depending on the product shape, processing temperature and line speed, there are specific challenges that need to be taken into account when selecting the technology:

Rotation and movement

Extruded products such as cables or hoses often run through the line rotating or slightly oscillating. A synchronized print output with suitable sensors is essential for exact positioning of the marking.

High temperatures & variety of materials

Many materials are still processed hot during extrusion. In addition, the surface properties vary greatly - from smooth PVC to rough rubber or silicone. Inks and laser settings must be temperature- and material-tolerant.

Speed and clock rate

The production speed in extrusion is often very high - several hundred meters per minute are not uncommon. The marking must dry quickly, remain legible and be applied without interruption.

Suitable technologies

The marking of cables, pipes and other extruded products requires systems that can handle high speeds, rotating products and different material surfaces. Depending on the application, different technologies are used - all optimized for continuous use in extrusion.

Get in touch with us

Laser marking

Lasers offer wear-free, permanent marking - particularly suitable for smooth, thermally activatable materials. Depending on the application, CO₂ or fiber lasers are used. Prerequisite: The surface must be laser-markable.

Particularly suitable for:

- Permanent markings without ink

- Sharp texts or check codes

- Applications with high abrasion resistance requirements

Continuous Inkjet (CIJ)

CIJ systems are the preferred solution for extrusion marking. They enable non-contact, fast and flexible marking - even on rotating or moving products. With specially developed inks, even adhesion-critical materials such as PE, PVC or rubber can be reliably printed.

Particularly suitable for:

- Serial numbers, logos or meter specifications

- Products with a round or flexible surface

- High line speeds and continuous operation

The CHROMOS way to the optimum solution

Understanding the application

Together we analyze your extrusion line, the material requirements and the desired marking - from meter specifications and serial numbers to logos or inspection codes.

Suggest technology and implementation

Based on product shape, line speed and environmental influences, we show suitable technologies - tailored to ink adhesion, drying, legibility and positioning.

Check feasibility

We validate print quality and process reliability in realistic tests - directly on your materials, taking rotation, speed and ambient conditions into account.

Support through to commissioning

From the selection of the right solution through to integration into your line, we support you with technical experience, extrusion expertise and reliable support.

Our tip: Get advice from our experts

Not every surface can be marked equally well - and not every technology works at high speeds or in harsh environments.

We help you find the optimum solution for your extrusion line - reliable, easy to read and tailored to the material, product shape and production conditions.

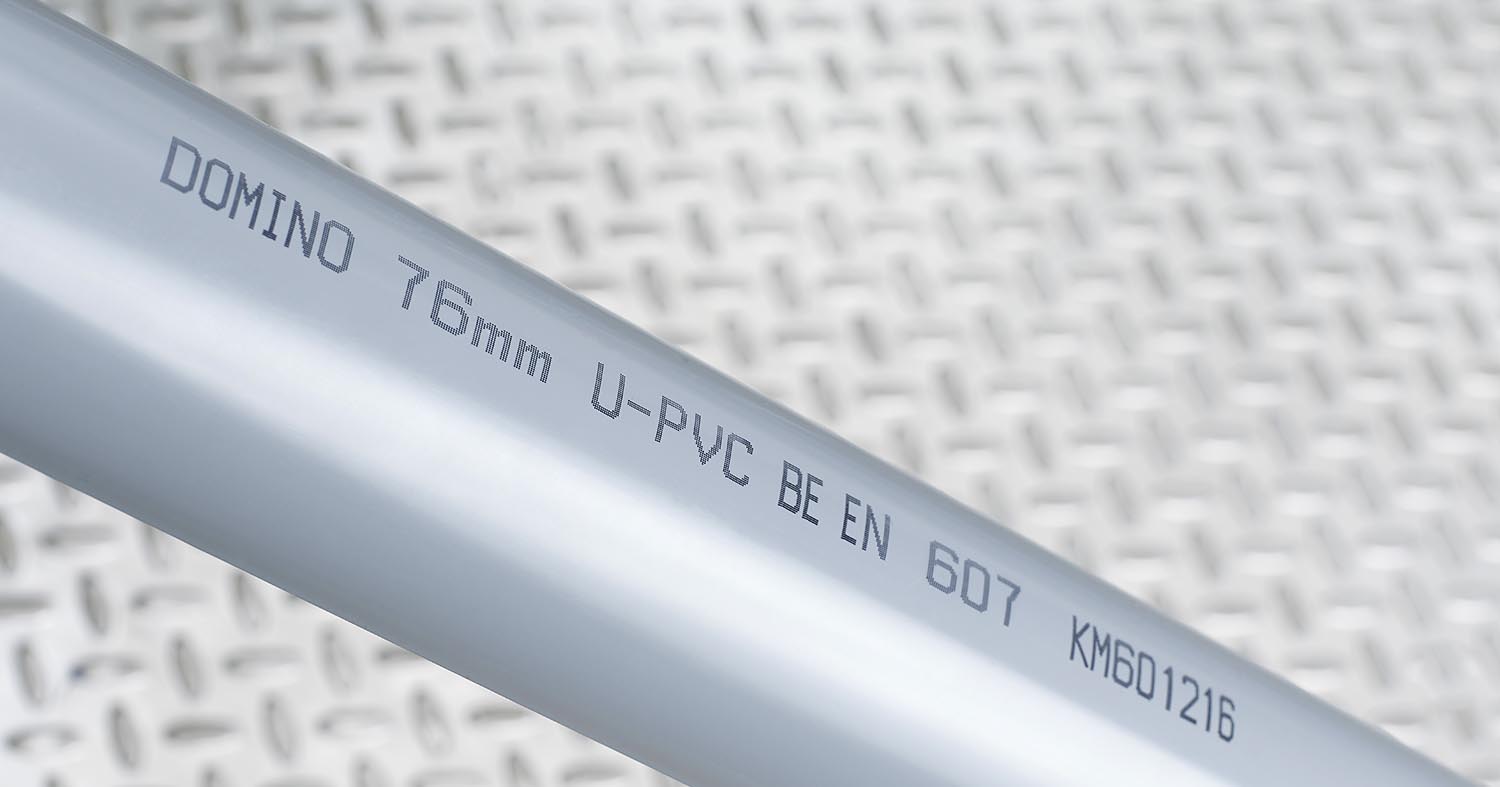

Case study: CIJ labeling at Pipelife

At pipe manufacturer Pipelife, plastic pipes are printed with variable product and traceability data directly in the extrusion line - at a line speed of up to 240 m/min. The CIJ systems from Domino enable high-contrast and durable marking, even on smooth, black PE surfaces.

"We need a solution that can keep up with the speed of our line - without compromising on print quality."

- Pipelife, Ireland

Technology: Domino Ax350i Continuous Inkjet

Product: PE tubes

Special feature: High-speed, high-contrast ink, low-maintenance system

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!