Marking wood and fiberboards

Reliable marking on rough, porous and demanding surfaces - from solid wood to OSB.

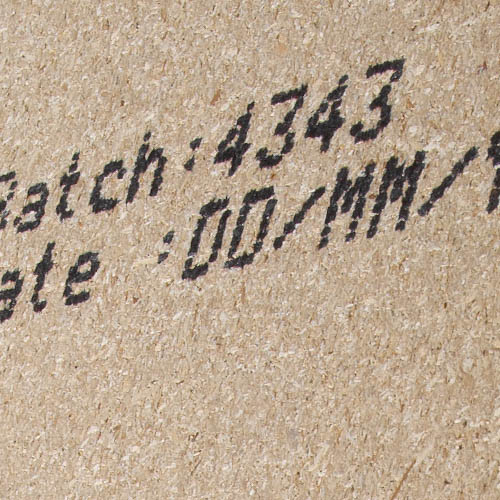

In wood and panel processing, marking is an indispensable component - whether for product identification, traceability or logistics. Unlike smooth packaging films, materials such as plywood, OSB, MDF or chipboard place special demands on the printing technology.

Marking often has to be carried out under harsh conditions - e.g. on absorbent, dusty or damp surfaces. At the same time, codes, texts or logos must remain clearly visible and permanently legible on large-surface materials - often at high line speeds and changing formats.

Get in touch with usWhy is the labeling of wood and fiberboard important?

Traceability and identification

Production data, batch numbers and manufacturer information are key pieces of information in wood processing - whether for internal processes, quality control or legal requirements. Clear and permanent labeling ensures transparency along the entire supply chain.

Logistics and warehouse management

Markings on the panel surface or on the side edge enable clear allocation in the warehouse and during transportation. Easy-to-read texts, barcodes or codes simplify automatic recording and minimize mix-ups.

Visibility and brand presence

The visual quality of the marking is particularly important for visible components or branded products - such as logos, quality marks or test certificates. The marking must also be clearly visible on rough or colored surfaces.

Challenges in the marking of wood and fiberboards

Depending on the material and production environment, the marking of wood and panel materials involves special technical requirements:

Surface finish

Wood, OSB, MDF or chipboard often have rough, porous or uneven structures. The marking must also adhere to absorbent or fibrous surfaces and remain legible - without running or losing contrast.

Dust and environmental influences

In many production environments, the air is dusty, the material is damp or exposed to heavy abrasion. This places high demands on print quality, adhesion and durability of the marking - especially for ink solutions.

Format size and print position

Wood and fiberboards often have large dimensions and are processed in different layers. The marking must also be securely applied to side panels, edges or moving materials - often with variable information.

Suitable technologies

Various technologies are used for marking film packaging, depending on the application - including thermal transfer printing (TTO), laser and continuous inkjet (CIJ).

The most suitable solution depends on the type of film, the packaging process and the requirements for legibility, durability and production speed, among other things.

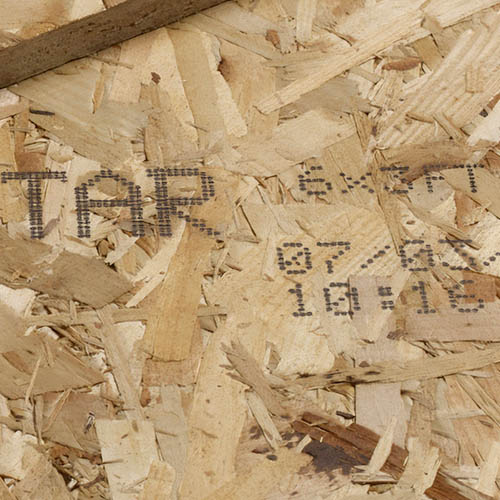

Drop-on-demand (large print)

DOD systems - also known as large character printers - are ideal for absorbent and rough surfaces. They apply large, highly visible characters directly onto wooden panels, e.g. for logistics codes, quality marks or company names.

Particularly suitable for:

- Rough and untreated wooden surfaces

- Large print content (logos, specifications)

- dusty production environments

Continuous Inkjet (CIJ)

Continuous Inkjet (CIJ)

CIJ systems enable non-contact marking with small to medium character sizes. They are particularly suitable for variable data, texts or serial numbers - even with irregular surfaces and high cycle rates.

Particularly suitable for:

- Moving or structured panels

- small to medium font sizes

- Variable texts or code formats

Laser

Lasers create abrasion-resistant markings on suitable wood and board materials - by engraving or color change. The marking is permanently legible and does not require inks or consumables.

Particularly suitable for:

- Fine markings, logos or test symbols

- Applications with high durability requirements

- Painted, coated or thermally treatable surfaces

The CHROMOS way to the optimum solution

Understanding the application

Together we analyze your production environment, the material to be marked and the requirements for legibility, durability and placement - whether on solid wood, fiberboard or OSB.

Suggest technology and implementation

We show you suitable technologies for your line - tailored to the surface structure, line speed and the desired print size. We also take into account harsh environments, changing formats and variable content.

Check feasibility

We validate the print image, adhesion and contrast in realistic tests - tailored to your specific panel materials and processes.

Support through to commissioning

From selecting the right technology to integration and training, we accompany you with experience, technical precision and reliable support.

Our tip: Get advice from our experts

Not every wood or fiberboard can be marked in the same way - and not every technology is suitable for every surface, line environment or format variance.

We help you to find the optimum solution for your production - high-contrast, robust and reliable under real conditions.

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!