Labeling cardboard packaging

Precise, permanent codes on folding boxes, trays and shipping cartons - tailored to the material, application and production line.

Cardboard packaging is used in numerous forms - from printed folding boxes to sturdy trays and shipping cartons. Each material has its own coding requirements: smooth or absorbent surfaces, high line speed or robust legibility in the logistics process.

With the right technology - whether inkjet, laser or label - coding can be implemented efficiently and permanently. It is crucial that the print position, material and content are perfectly coordinated. This is exactly where we come in.

Get in touch with usWhy is the labeling of cardboard packaging important?

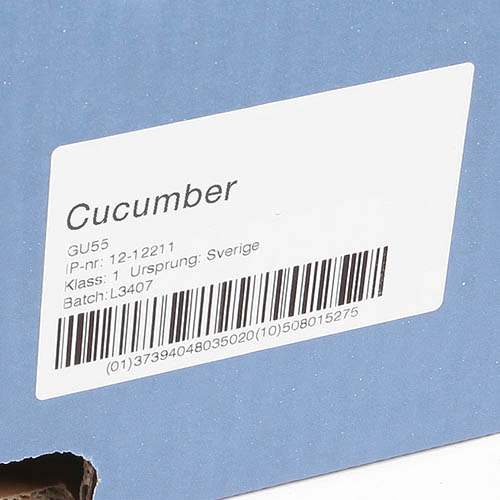

Trace products:

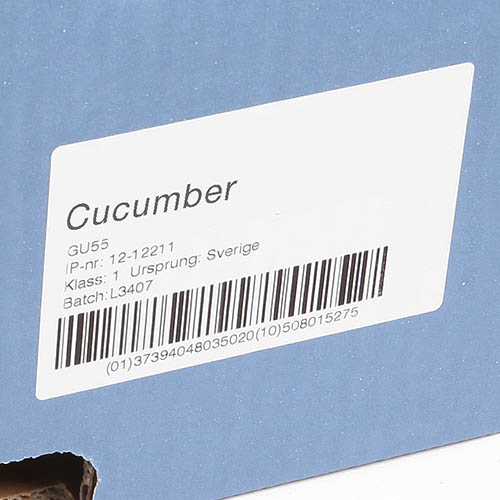

Batch, serial or manufacturing numbers on carton packaging are crucial for traceability - whether in the context of legal regulations, quality assurance or in the event of product recalls.

Control logistics and storage:

Cardboard packaging is often used as secondary or tertiary packaging. Clearly legible codes, barcodes or DataMatrix markings facilitate the internal flow of materials, warehouse logistics and automated shipping.

Inform consumers:

Variable information such as best-before dates, product numbers or application information must be clearly visible and permanently legible on folding cartons or display packaging - even under demanding conditions.

Typical cardboard packaging at a glance

Not all cartons are the same: the shape, surface and labeling requirements differ significantly depending on the packaging level and intended use. Three types are particularly relevant:

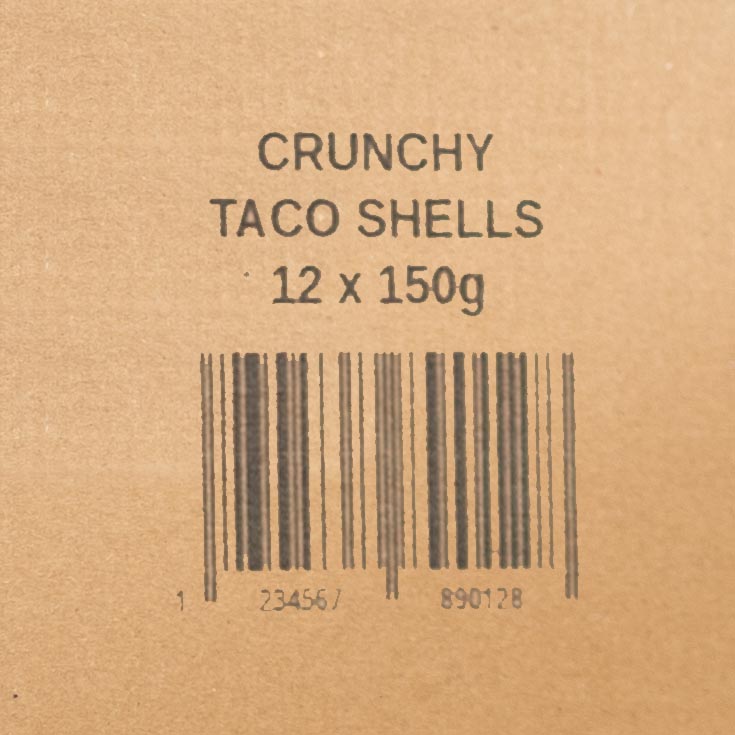

Folding boxes

The classic individual packaging - often printed with expiration dates, batch numbers or traceability codes. Particularly common in the food, cosmetics and pharmaceutical industries.

Collective packaging / trays

Secondary packaging that bundles several individual products - often as a display unit in retail or for transportation on pallets. Marking usually with plain text or barcodes.

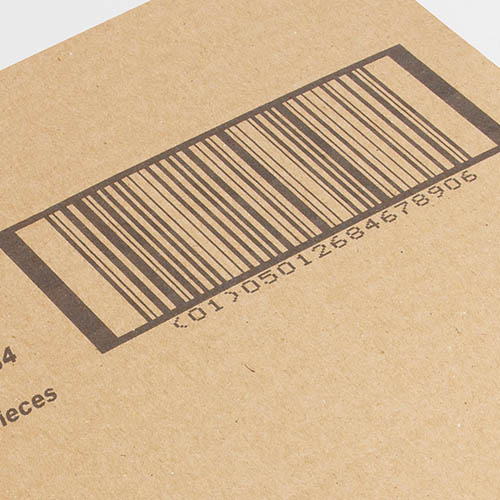

Shipping cartons

Sturdy corrugated cardboard packaging for storage, shipping and logistics. Require large, easy-to-read codes or labels to control material flows.

Challenges in the labeling of cardboard packaging

Cartonboard is a versatile but technically demanding packaging material. Depending on the surface, packaging level and production environment, there are different challenges for the print image, legibility and process integration.

Surface finish

Depending on the application, cardboard can be absorbent, coated, varnished or textured. Choosing the right technology and ink is crucial to achieving a sharp, durable print image - without fraying or running.

Dust & production environment

Dust is often generated during the packaging and storage of cardboard packaging - whether through friction, cutting processes or the material itself. This can impair print heads or affect the adhesion of ink, especially at high cycle rates.

Packaging layers & print position

Whether folding carton, tray or shipping carton - each level has its own requirements: sometimes small text in a small space, sometimes large logistics codes or side labeling on corrugated cardboard. The technology must be flexible to integrate.

Suitable technologies

Various technologies are used for marking film packaging, depending on the application - including thermal transfer printing (TTO), laser and continuous inkjet (CIJ).

The most suitable solution depends on the type of film, the packaging process and the requirements for legibility, durability and production speed, among other things.

Thermal Inkjet (TIJ)

TIJ printers produce high-resolution texts, barcodes or DataMatrix codes on smooth or coated surfaces - ideal for folding boxes and smaller formats.

Particularly suitable for:

- Precise coding on folding boxes

- Variable data such as batches or expiry dates

- Industries with high requirements for legibility and purity (e.g. pharmaceuticals, cosmetics)

Laser

Lasers generate permanently legible codes by removing material or changing color - without ink or labels. Depending on the type of cardboard, CO2 or fiber lasers are used.

Particularly suitable for:

- Folding cartons with coated or lacquered surface

- Applications with high line speed

- Tamper-proof and consumable-free labeling

Continuous Inkjet (CIJ)

CIJ systems are versatile and also prove their worth on uneven or porous cardboard surfaces - especially when speed counts.

Particularly suitable for

- Simple coding on trays or shipping cartons

- Production lines with high cycle rates

- Applications with high ink requirements and robust setup

Drop-on-demand (large print)

These inkjet printers specialize in large, high-contrast lettering - for example on corrugated cardboard shipping boxes.

Particularly suitable for:

- Shipping cartons and outer packaging

- Easy-to-read logistics codes, texts or symbols

- Applications with variable carton sizes and large print fields

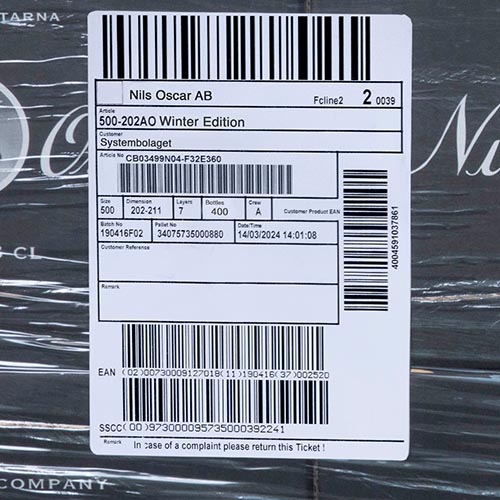

Labeler / Print & Apply

Automated labeling systems apply printed labels precisely to various carton formats - e.g. for logistics or traceability.

Particularly suitable for:

- Collective packaging and shipping cartons

- multi-line information, logos or changing content

- Lines with changing products or flexible layouts

The CHROMOS way to the optimum solution

Understanding the application

Whether folding carton, tray or shipping carton: together we analyze your production conditions, material properties and requirements for print image, legibility and durability.

Suggest technology and implementation

Based on your application, we will show you suitable printing technologies and specific implementation options - tailored to line speed, packaging type and marking position.

Check feasibility

In practical tests, we validate the quality, adhesion and material compatibility of the marking - and ensure that the solution fits reliably into your processes.

Support right through to commissioning

From device selection to training - our team will accompany you with technical expertise and reliable support.

Our tip: Get advice from our experts

Not all cartons are the same - and every line has different coding requirements.

We support you in finding the optimum technology for your folding cartons, trays or shipping cartons - reliable, high-contrast and tailored to your production conditions.

Use case: Shipping labeling at Jollyroom

The Nordic online retailer Jollyroom sends thousands of parcels every day. To meet the increasing demands for speed and traceability, the company relies on an automated labeling solution with Domino Print & Apply systems.

With the reliable M-Series labelers, shipping labels are precisely applied to cartons - with full integration into the existing warehouse management system. This ensures fast processes, error-free shipping data and maximum efficiency.

"The system simply works - it is stable, low-maintenance and saves time."

- Jollyroom Logistics Manager

Technology: Domino M-Series Print & Apply

Packaging type: Shipping cartons / tertiary packaging

Special feature: Integration into automated conveyor line

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!