Marking on glass

Reliable marking of glass containers with laser or ink - permanent, high-contrast and legible

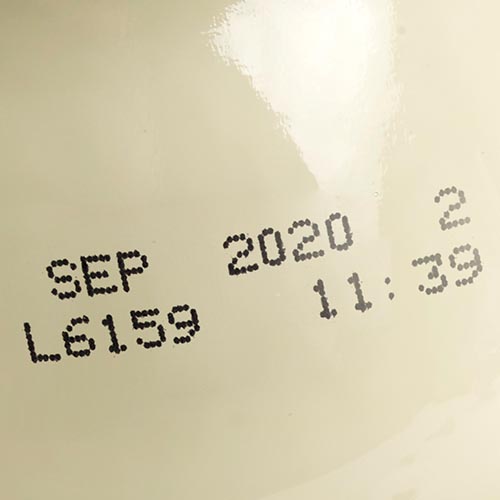

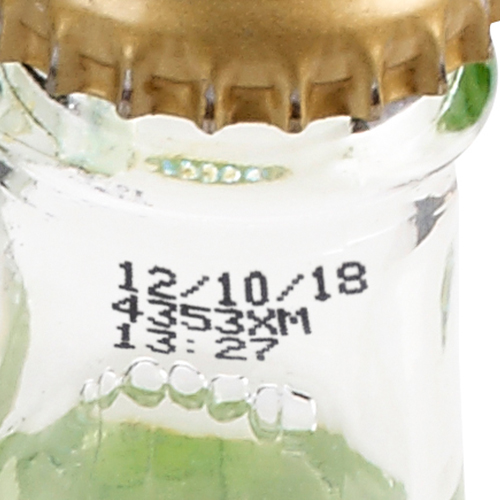

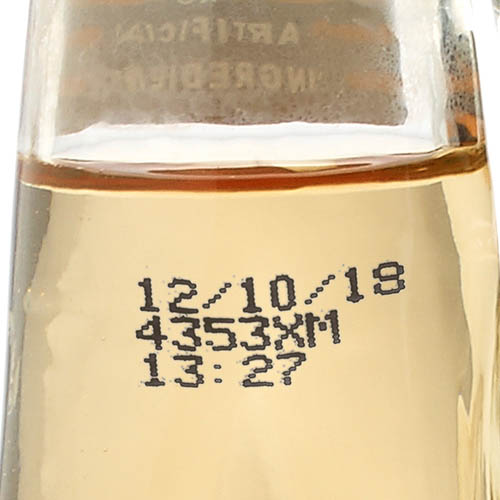

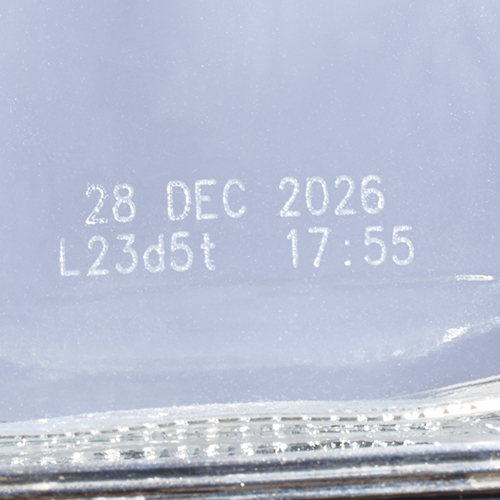

Marking on glass plays an important role in many industries - from beverages to pharmaceuticals and cosmetics. Glass bottles, ampoules and containers often need to be marked with batch codes, expiration dates or serial numbers. Due to the smooth surface and high transparency, the industrial marking of glass is technically challenging - but can be reliably solved with the right technologies.

Get in touch with usWhy is the labeling of glass important?

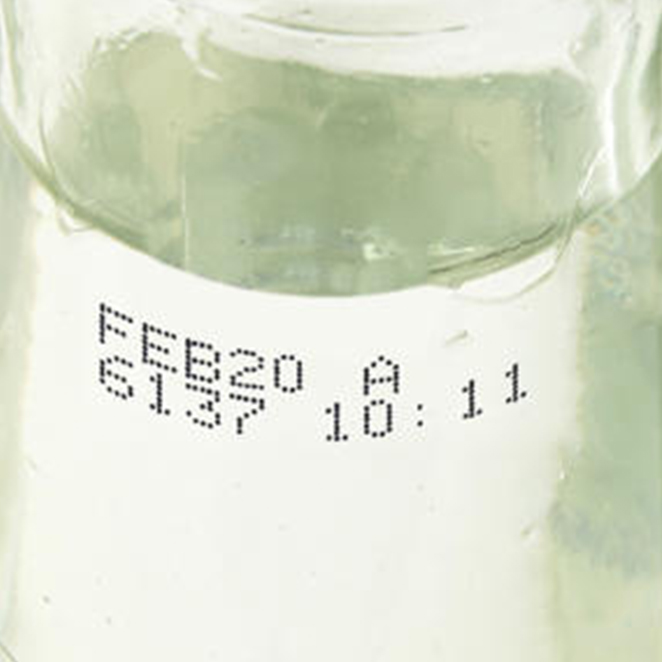

Ensure traceability: Serial numbers and batch codes enable complete documentation on glass bottles, ampoules and other glass containers.

Product safety & information: Expiry dates and production times must also be clearly legible on glass - regardless of shape or surface.

Protect brand integrity: Logos and manufacturer-specific features strengthen the brand image and prevent counterfeiting.

Challenges in glass labeling

The special properties of glass pose a number of technical challenges:

Liability

Many standard inks adhere poorly to glass or remain smudgeable. It is therefore crucial to use special glass inks or to switch to non-contact laser methods. The glass surface (coated, frosted, smooth) also plays a role in adhesion.

Contrast & legibility

High visibility is crucial on transparent or dark glass - especially for batch or best-before date codes, which must be machine-readable. Choosing the right ink color (e.g. white or yellow on dark glass) or the right laser wavelength has a significant impact on legibility.

Consistency

Markings must be abrasion-resistant, smudge-proof and resistant to chemicals - especially for reusable containers, storage in refrigerated areas or transportation in humid environments. The cleaning process (e.g. in the beverage industry) also places high demands on the durability of the marking.

Suitable technologies

We use two main technologies for marking glass: laser marking and continuous inkjet (CIJ).

The most suitable solution depends on the product type, line speed and requirements for durability and legibility, among other things.

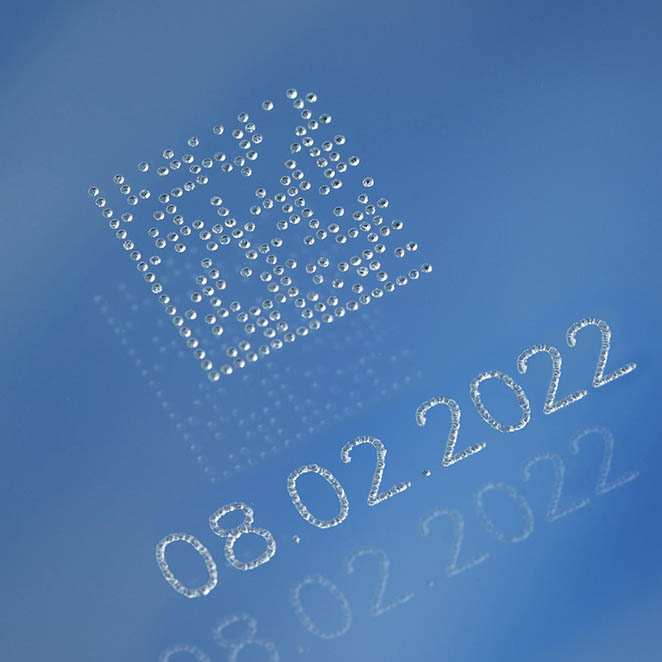

Laser marking

Lasers create permanently legible markings - either by engraving or by ablation on coated surfaces. Particularly suitable for:

- High-contrast marking on tinted or frosted glass

- High demands on durability

- Fine codes or graphics

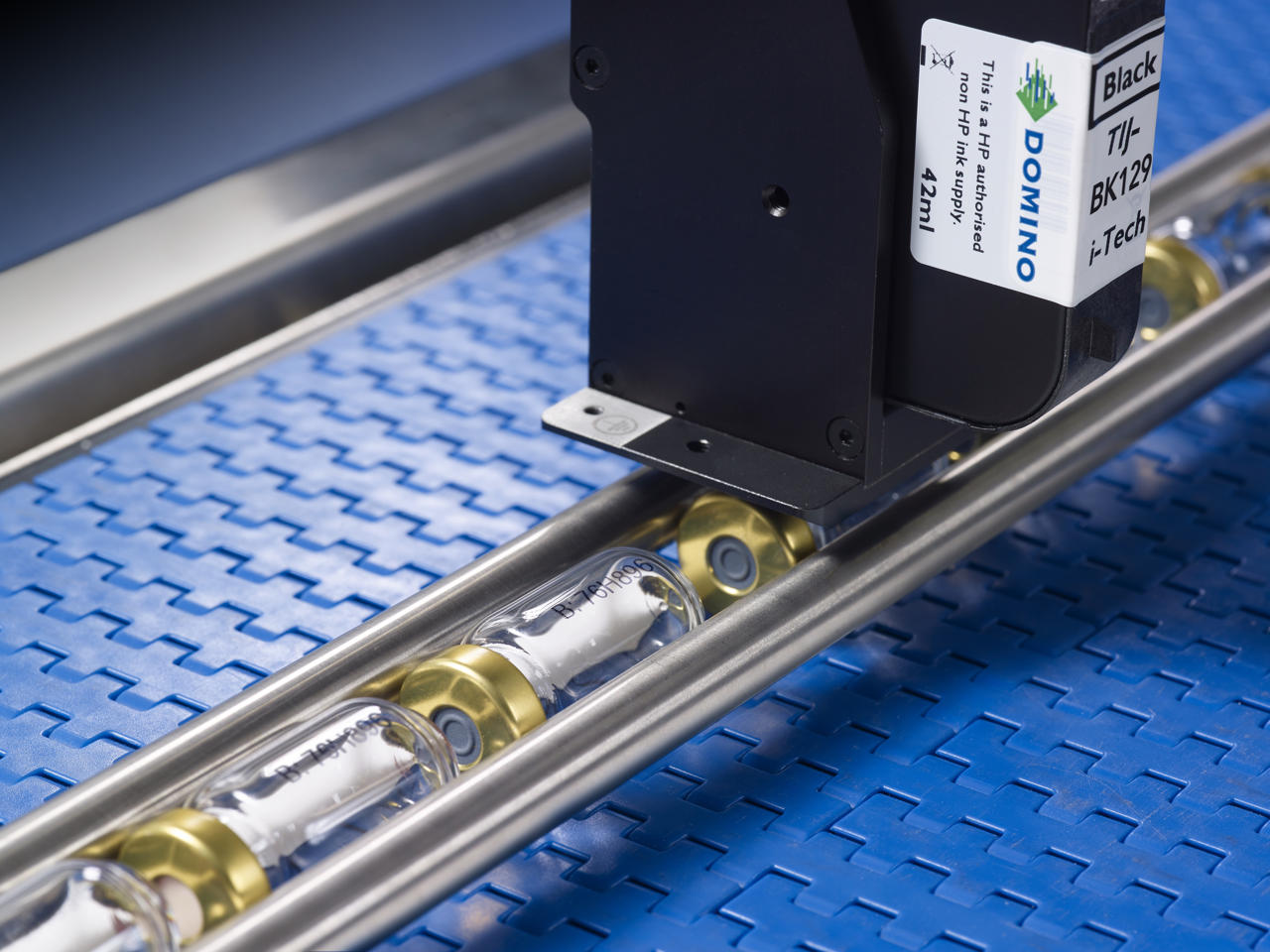

Continuous Inkjet (CIJ)

CIJ printers with specially developed inks enable flexible, fast and well-adhering markings. Typical advantages:

- Quick-drying inks for glass

- Easy-to-read print images (even on convex surfaces)

- Suitable for high line speeds

The CHROMOS way to the optimum solution

Understanding requirements

You describe your application to us - we clarify materials, environment, production conditions and quality requirements.

Propose a solution

Based on your situation, we will show you suitable technologies and possible implementation options.

Testing feasibility

We test the quality and durability of the marking in realistic trials - tailored to your line speed and processes.

Integration and support

We assist you with the selection, implementation and commissioning - with technical support and many years of experience.

Our tip: Get advice from our experts

Not all glass is the same - and not every marking technology works equally well in every environment.

We help you to find the right process for your production line and your glass product - efficient, durable and easy to read.

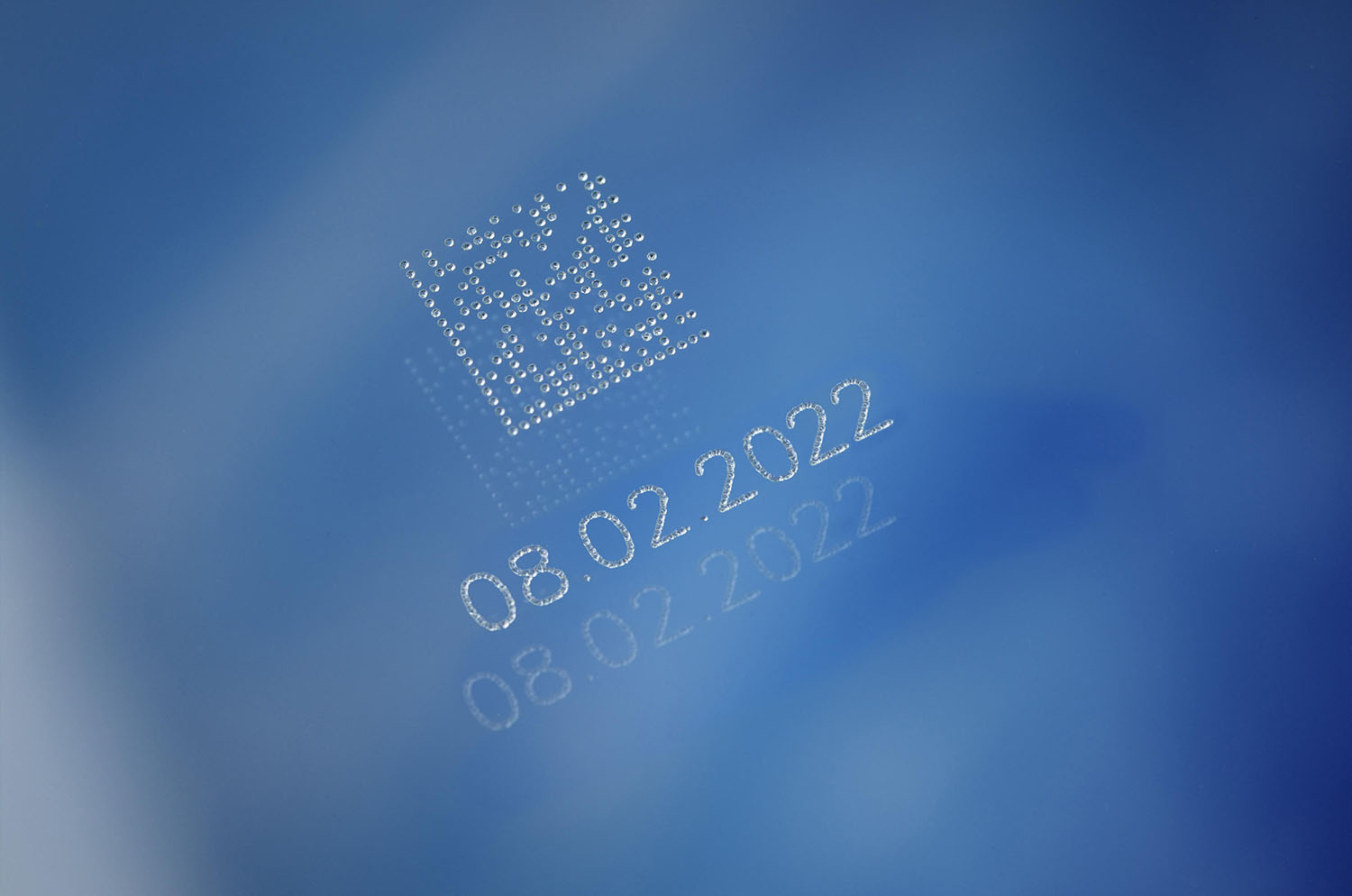

Successful in use: glass labeling in wine production

Caballero Group (Spain) relies on the Domino D-Series laser to mark its glass bottles. A laser was seamlessly integrated into the existing line at the traditional wine production facility in El Puerto de Santa María and Jerez.

Challenge:

Reliable marking on glass in a humid environment with sensitive products.

Solution:

D-Series laser coding with high legibility, minimal maintenance and robust operation - even in difficult environmental conditions.

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!