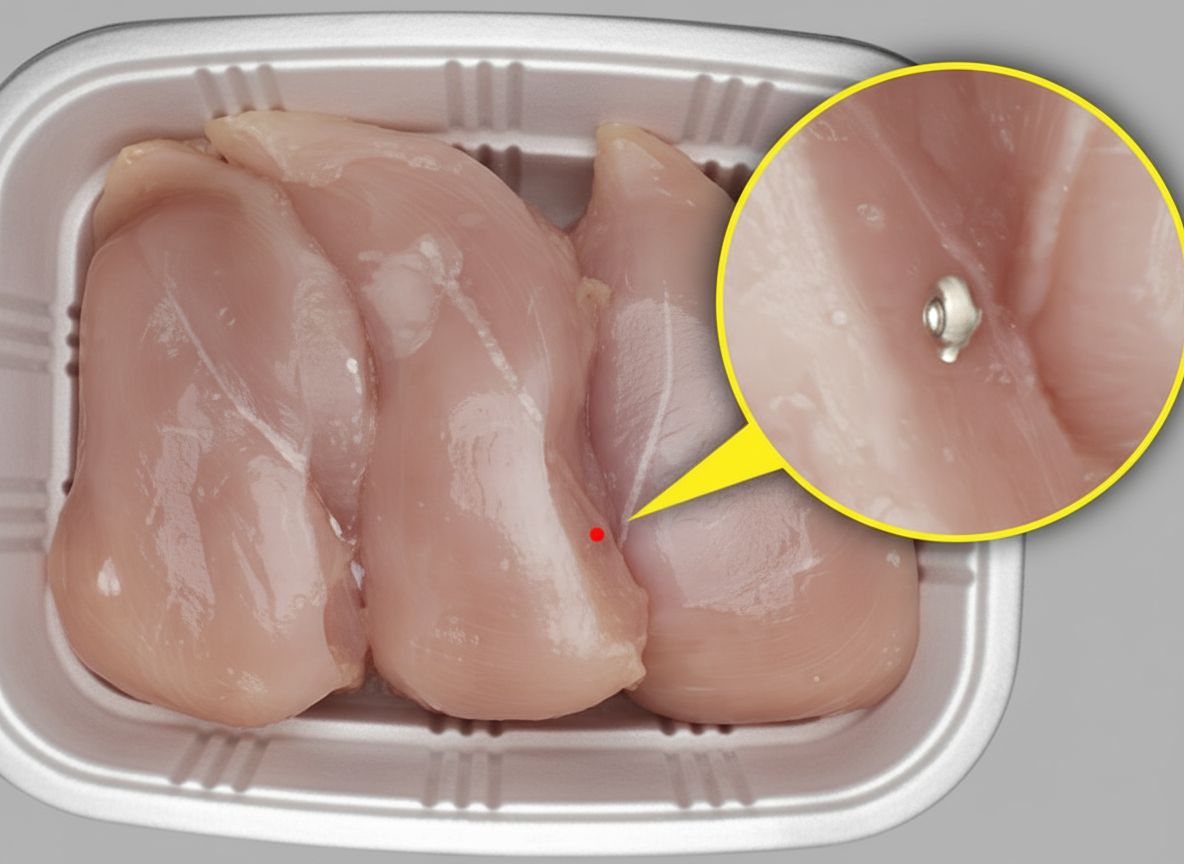

Optical contamination detection in production

Machine vision systems identify foreign bodies and particles in food, pharmaceutical and industrial goods - quickly, safely and inline.

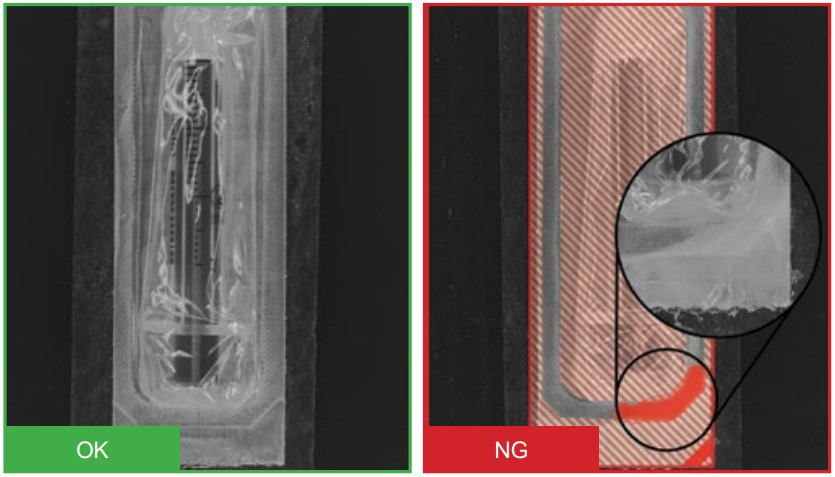

Foreign bodies in products are among the most critical faults in industrial production. Even the smallest particles can lead to product recalls, loss of image and high costs. Optical vision systems can reliably detect contaminants such as dust, fibers, plastic or metal fragments. Modern image processing combines cameras, lighting and AI algorithms to reliably identify even hard-to-see contaminants. This protects product quality and ensures compliance with regulatory requirements.

Get in touch with usWhy is optical packaging inspection important?

Ensuring product safety: Foreign bodies in food, pharmaceutical or consumer goods can endanger health and compromise the safety of end customers. Optical contamination detection ensures that only flawless products reach the market.

Avoid recalls and costs: A single production error can affect entire batches and lead to expensive recalls. Inline systems detect contamination at an early stage and prevent faulty products from being delivered.

Ensuring trust in the brand: Clean and safe products are the basis for customer trust. Even the smallest impurities can be detected through visual inspection - and strengthen the quality perception of the brand in the long term.

Challenges in the use of vision systems for foreign object detection

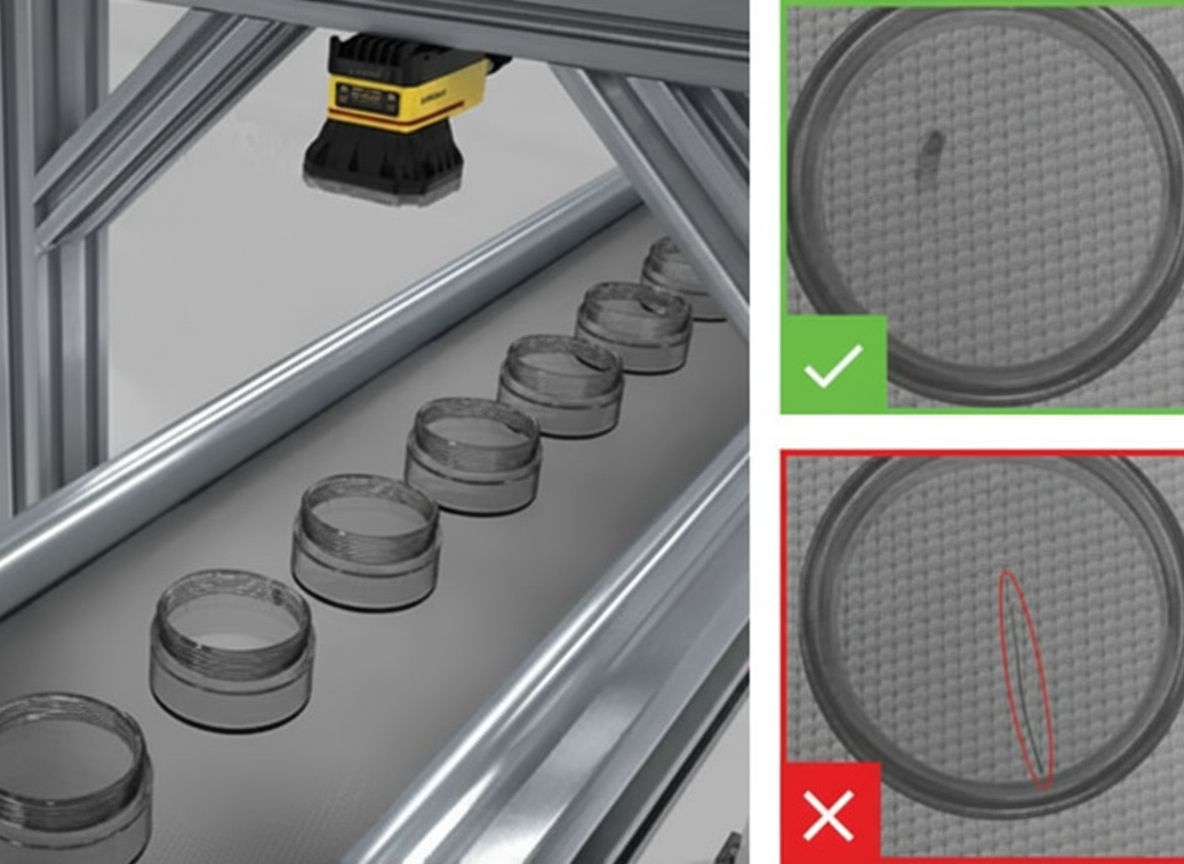

Detecting foreign objects sounds simple, but in practice it is technically demanding. Different materials, varying surfaces and high line speeds place high demands on cameras, lighting and algorithms. In order for vision systems to work reliably, they must be adapted to the specific products and environments.

Different materials and products

Plastics, powders, liquids or tablets each have their own optical properties. Foreign bodies do not always stand out clearly, which requires a careful selection of camera resolution, spectrum and lighting.

Varying levels of contamination

Foreign bodies come in very different shapes and sizes - from dust particles to larger fragments. Systems must be robust enough to reliably detect this variety, even if the defect pattern is rare or irregular.

Production conditions and speed

In industrial production lines, products often move at high speed and under changing light conditions. Vision systems must detect and evaluate the smallest particles in real time without interrupting the production flow.

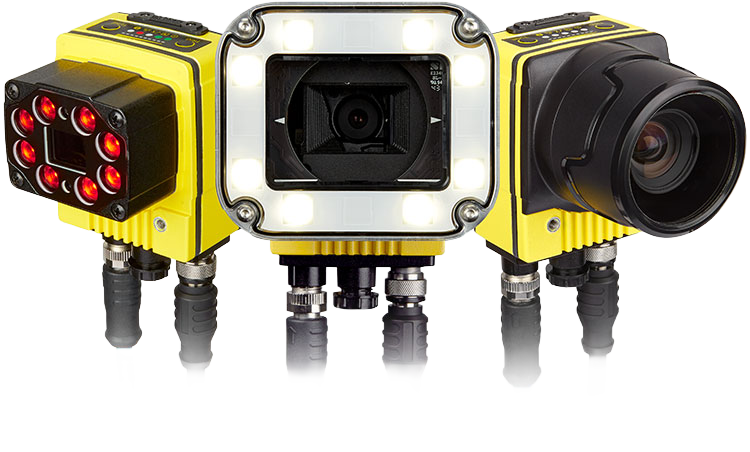

Suitable machine vision technologies

The detection of foreign objects requires systems that make even the smallest deviations visible. Depending on the product and requirements, different technologies are used - from flexible industrial cameras and compact smart cameras to AI-supported processes.

Get in touch with us

Industrial cameras with external evaluation

High-resolution cameras in combination with coordinated lighting provide detailed images that are analyzed by powerful software.

- Flexible combination of optics, camera and evaluation PC

- Suitable for different products and packaging types

- Expandable for multi-camera solutions and large lines

Smart cameras

Compact systems with integrated evaluation, which are particularly suitable for clearly defined types of contamination.

- No external PC required, fast deployment

- Standardized tools for typical inspection tasks

- Space-saving and easy to integrate into existing lines

AI-supported processes

Deep learning algorithms are ideal when foreign objects occur variably or are difficult to recognize visually.

- Robust against changing fault patterns and rare contamination

- Able to learn on the basis of real production data

- Supplements conventional methods and increases the detection rate

The CHROMOS way to the optimum solution

Risk analysis and target definition

We work with you to analyze which types of contamination are relevant in your production and determine which characteristics must be reliably detected.

Selection and test setup

Cameras, lighting and software are combined in such a way that even small and difficult to see foreign objects can be detected. We carry out initial practical tests with your products in the line.

Integration into production

Our systems are integrated in such a way that results are available in real time and outfeeds are automatic. Interfaces to existing control systems ensure smooth integration.

Ongoing support and optimization

We assist you with product changes and process adjustments and ensure that detection remains reliable even with new batches - with local service and support.

Contact us

Our experts will be happy to help you. Get in touch with us!