Labeling plastic and PET bottles

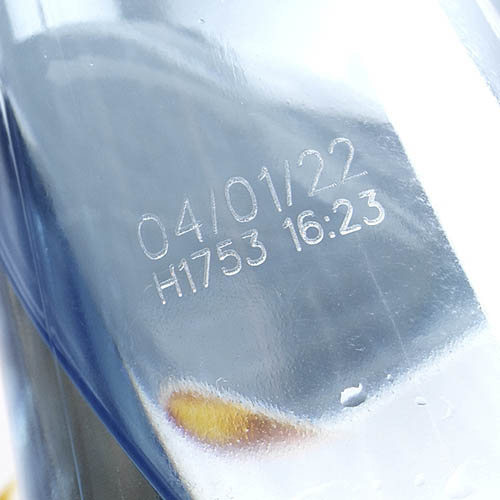

Clear, abrasion-resistant product labeling on plastic bottles - with ink or laser, directly on your line.

Whether in the beverage industry, cosmetics or household chemicals - plastic bottles are standard in many sectors. To ensure that every product remains traceable, expiration dates, batch numbers or production codes must be printed directly on the packaging.

This is no trivial matter: PET, HDPE, PP and other plastics have different surfaces and properties. Some are slightly textured, others are particularly smooth or moist. This has a direct influence on adhesion, drying time and legibility of the marking.

We will show you how to label plastic packaging reliably and efficiently - with the right technologies for your line.

Get in touch with usWhy is the labeling of plastic bottles important?

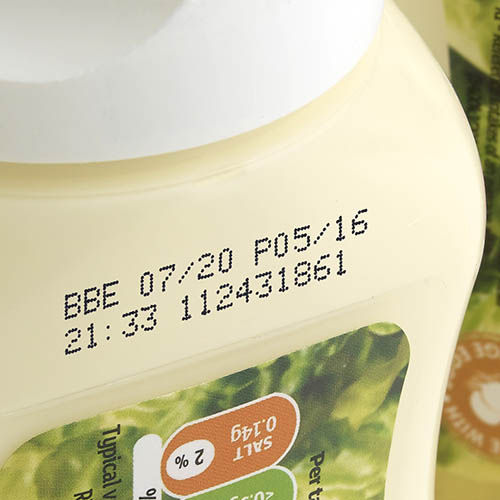

Ensure traceability: Production data such as batch or serial numbers enable seamless traceability - essential for recalls, quality management and regulatory requirements.

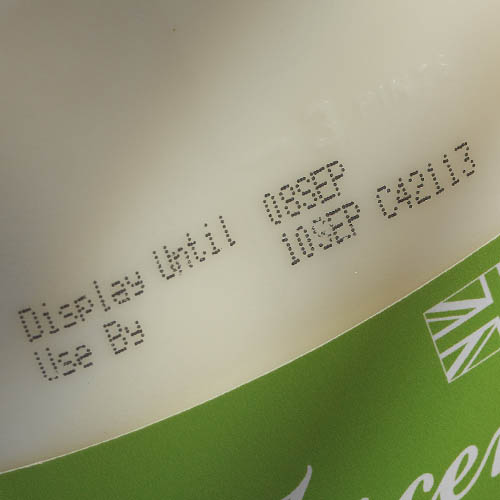

Inform consumers: Best-before dates, filling times or other variable information must be clearly legible directly on the bottle or label - often under difficult conditions such as high line speeds or humidity.

Marking without a label:

In certain applications, direct marking by laser can be a sustainable alternative to labels. The marking is made directly on the bottle - abrasion-resistant, tamper-proof and recycling-friendly.

Challenges in the labeling of plastic bottles

The special properties of PET and other plastics pose a number of technical challenges:

Adhesion & drying

Many standard inks do not adhere well to plastics such as PET or HDPE - especially with damp or statically charged bottles. The inks must be specially formulated and dry quickly to avoid smearing.

Deformation & flexibility

Plastic bottles are often flexible or have uneven, curved surfaces. This can make positioning and legibility of the marking difficult - especially with very small or multi-line codes.

Line speeds

In bottling, plastic bottles often run through the line at several hundred products per minute. Labelling must take place in real time - precisely, synchronized and without interruption.

Suitable technologies

We mainly use two technologies for marking plastic bottles - e.g. made of PET, HDPE or PP:

laser marking and continuous inkjet (CIJ).

The most suitable solution depends on the material, the line speed, the requirements for legibility and adhesion as well as the ambient conditions - especially in the case of moist or chilled products.

Get in touch with us

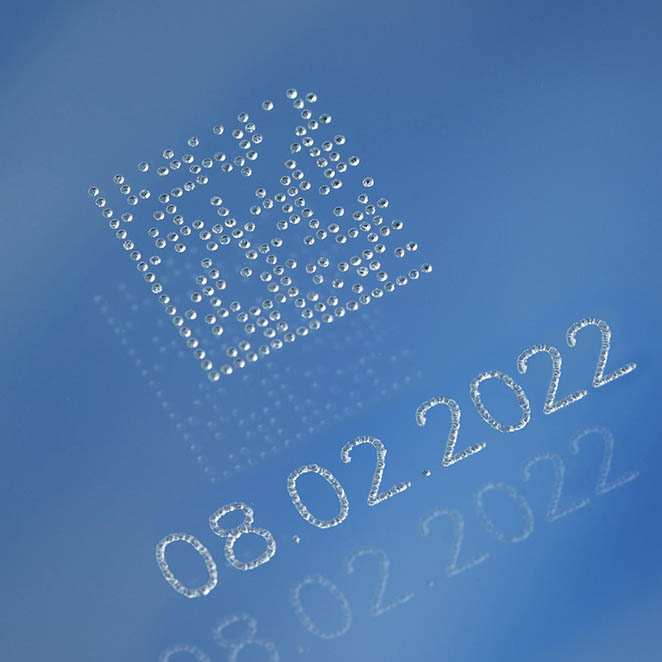

Laser marking

Lasers are ideal for permanently legible markings directly on the bottle - without consumables. Particularly advantageous for:

- high line speed and humid environment

- Requirements for durability, abrasion resistance and traceability

- Applications without labels - e.g. sustainable PET solutions

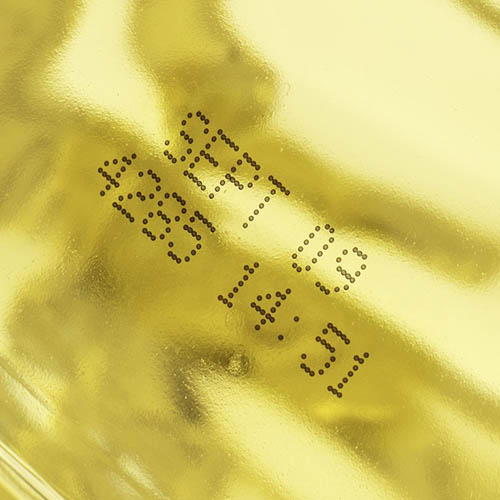

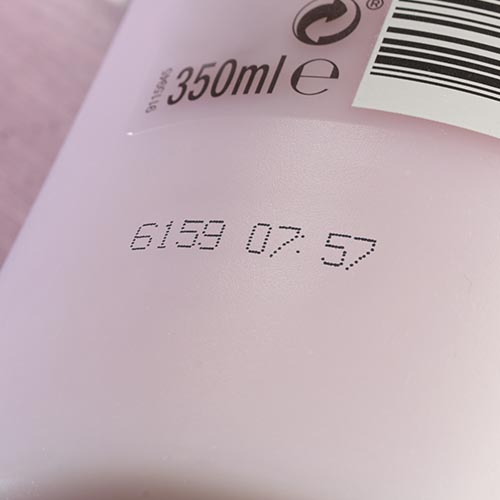

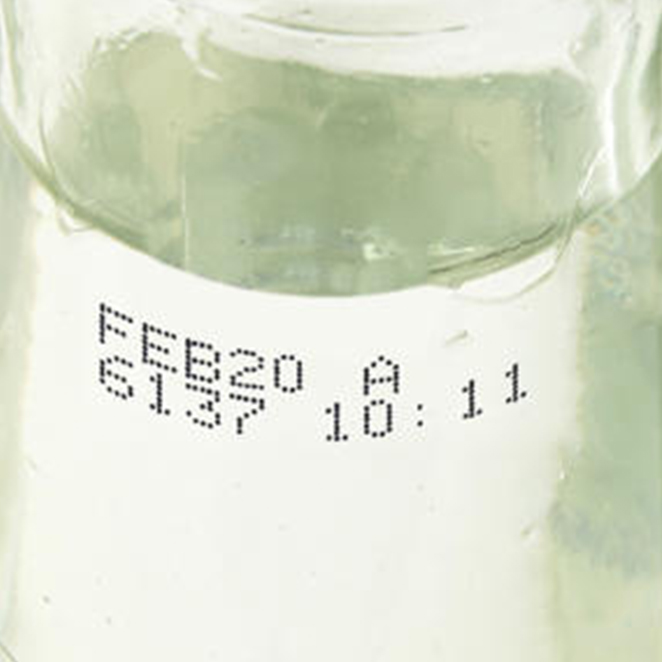

Continuous Inkjet (CIJ)

CIJ printers offer maximum flexibility and are specifically designed for demanding line environments. They are well suited for:

- Well-adhering codes with quick-drying ink on plastic

- Flexible printing positions for convex or irregular shapes

- High line speeds with variable data such as BBD and batches

The CHROMOS way to the optimum solution

Understanding the application

Whether PET, HDPE or other plastics: together we analyze your production conditions, material properties and requirements for print image and durability.

Suggest technology and implementation

Based on your application, we will show you suitable printing technologies and specific implementation options - to suit the line speed and product shape.

Check feasibility

In practical tests, we validate the quality and adhesion of the marking and ensure that the solution fits your process.

Support right through to commissioning

From device selection to training - our team will accompany you with technical expertise and reliable support.

Our tip: Get advice from our experts

Not all plastics are the same - and every line has different coding requirements.

We support you in finding the optimum technology for your PET or HDPE bottles - reliable, clean and tailored to your production conditions.

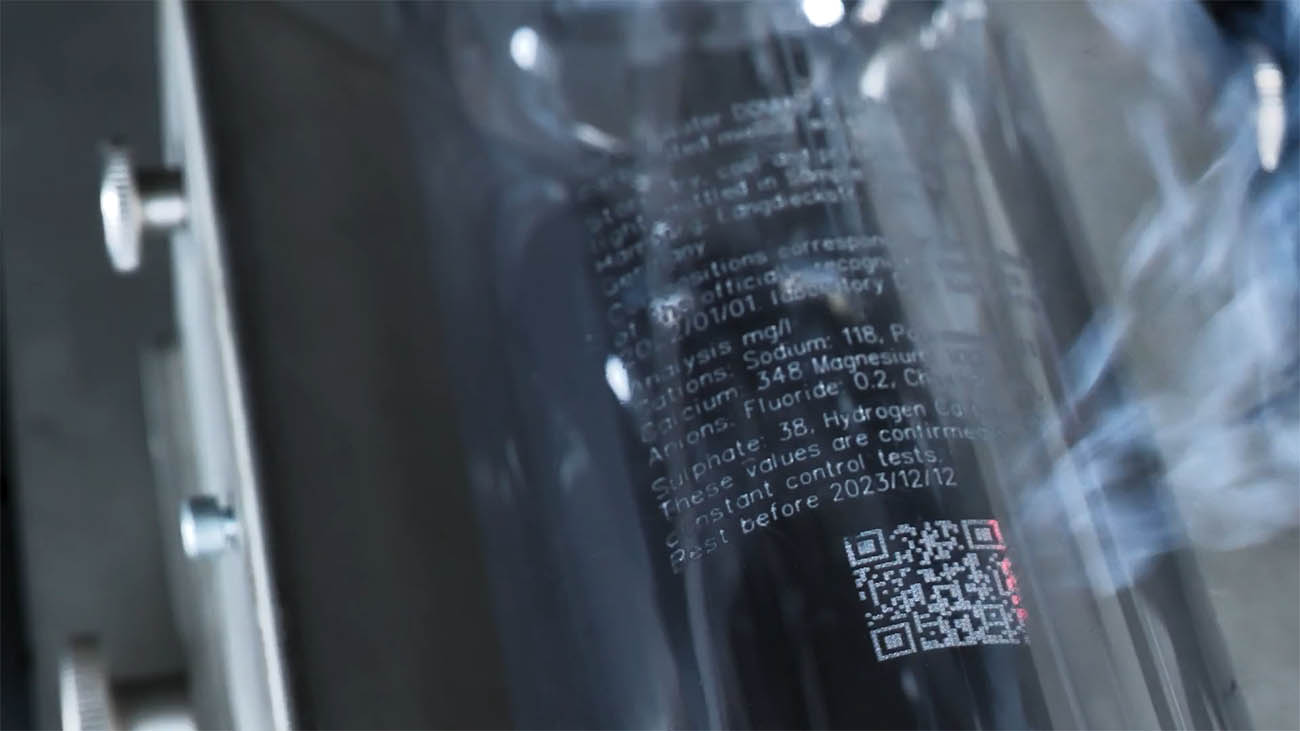

Case study: Reliable PET labeling at Adelholzener

The German mineral water producer Adelholzener Alpenquellen relies on Domino CO₂ lasers from the D-Series for marking PET bottles - directly in the high-speed line.

The marking is done with best-before data and production codes directly on the bottle - permanently legible, abrasion-resistant and without consumables. The lasers have been seamlessly integrated into existing Krones lines, with a line output of up to 60,000 bottles per hour.

"The tests at the Domino Laser Center under real conditions convinced us - especially of the D620i."

- Rudolf Kropf, Head of Electrical Engineering, Adelholzener Alpenquellen

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!