Camera-supported robot guidance

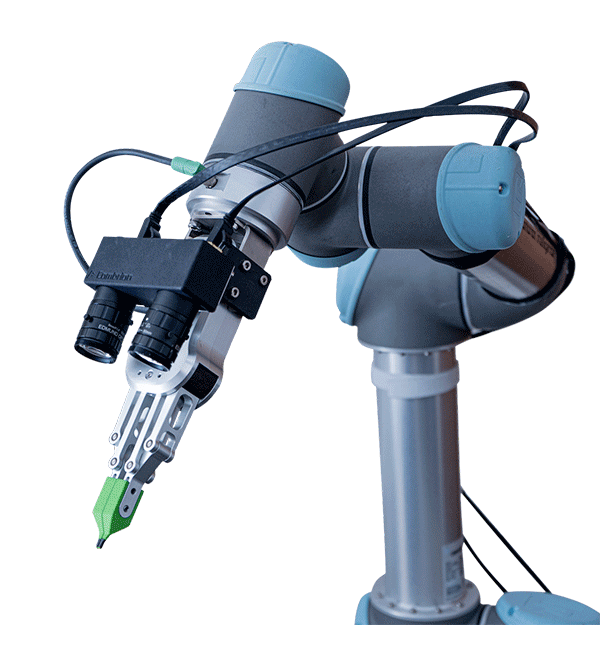

Machine vision systems make robots more flexible: they recognize objects reliably and position them precisely even if they are not perfectly aligned.

In modern production environments, robots are increasingly taking on complex handling tasks. To enable them to grip, assemble or place components precisely, they need exact information on the position and orientation of the objects. Camera-supported systems provide this data in real time, enabling flexible, reliable and efficient robot guidance. Machine vision offers a decisive advantage over purely mechanical solutions, especially when it comes to changing product variants or unstructured storage areas.

Get in touch with usWhy is camera-supported robot guidance important?

Flexibility instead of rigid feeding: Instead of expensive feeding systems with precisely positioned parts, vision systems enable flexible handling directly from the conveyor belt, tray or crate.

Automation of complex tasks: Components with variable orientation or complex geometry can also be handled automatically - even if they previously had to be sorted manually.

Reduced costs and effort: The combination of camera and robot eliminates the need for expensive mechanical adjustments. Conversion to new products is carried out on the software side - quickly and efficiently.

Precise transfer - even when moving: Thanks to intelligent image processing, parts can be precisely localized and oriented for gripping - even when moving on a moving conveyor belt.

Challenges when using vision systems for robot guidance

Camera-supported robot guidance requires more than simply recognizing an object - the precise determination of position and orientation in space is crucial. Particularly in dynamic environments with variable positions of parts or changing lighting conditions, maximum reliability is required. The challenge is to provide the robot in real time with all the relevant information it needs to interact with its environment without errors.

Variable position and orientation of parts

Workpieces are often in different positions or angles on conveyor belts or in boxes. The camera solution must be able to detect these deviations precisely in order to enable safe and repeatable gripping movements.

Disturbing influences in the environment

Reflections on shiny surfaces, fluctuating light conditions or partial coverage make reliable detection difficult. A robust image processing system must compensate for these factors and deliver stable results - even with varying materials and structures.

High cycle rates and real-time requirements

In many production lines, there is only a fraction of a second to identify an object, determine its position and adjust the gripping movement. Image processing and robot control must therefore be optimally coordinated and fast enough for the industrial cycle.

Suitable machine vision technologies

The choice of the right vision system depends heavily on the application: parts lying flat require different approaches than disorganized components in boxes. Each system consists of several components - camera, optics, lighting and evaluation - which must be coordinated with each other.

Get in touch with us

2D vision systems

Classic 2D systems capture images in the plane and are suitable for many standardized pick & place tasks. They provide precise position data as long as the parts are flat and no depth information is required.

- Camera with suitable optics for the field of view

- Illumination (e.g. ring light, line light) to make edges or contrasts visible

- Software tools for detecting contours, edges, markings or drill holes

- Typical application: Alignment of printed circuit boards, detection of labels or layers on a conveyor belt

3D vision systems

Depth information is crucial for chaotically provided parts or applications such as bin picking. 3D systems reconstruct the object in space and reliably transmit its position and orientation to the robot.

- Technologies: stereo cameras, time-of-flight cameras, structured lighting or laser triangulation

- Generation of point clouds or height maps for precise position determination

- Ideal for detecting overlapping or twisted parts

- Typical application: Removal of components from bulk material containers, palletizing of irregular packs

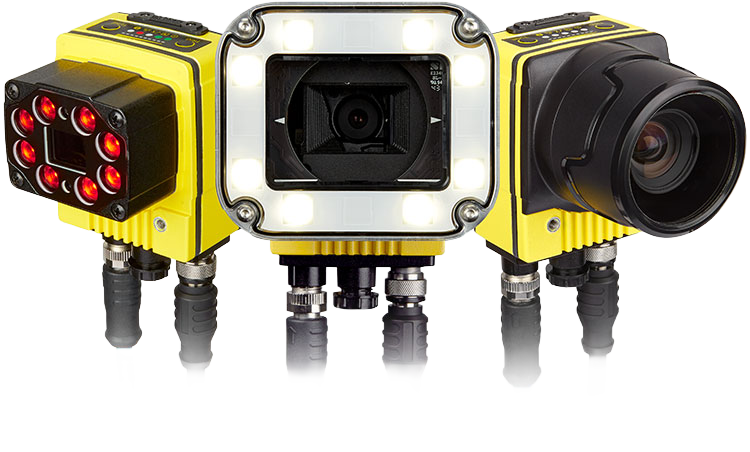

Smart cameras

Smart cameras combine image recording, lighting and evaluation in one compact device. They reduce integration costs and are particularly suitable when space is limited or the task is clearly defined.

- Built-in evaluation software, usually with preconfigured tools

- Partly with integrated lighting or autofocus

- Communication directly with the robot controller, no external PC required

- Typical application: standardized pick & place tasks, parts inspection at fixed stations

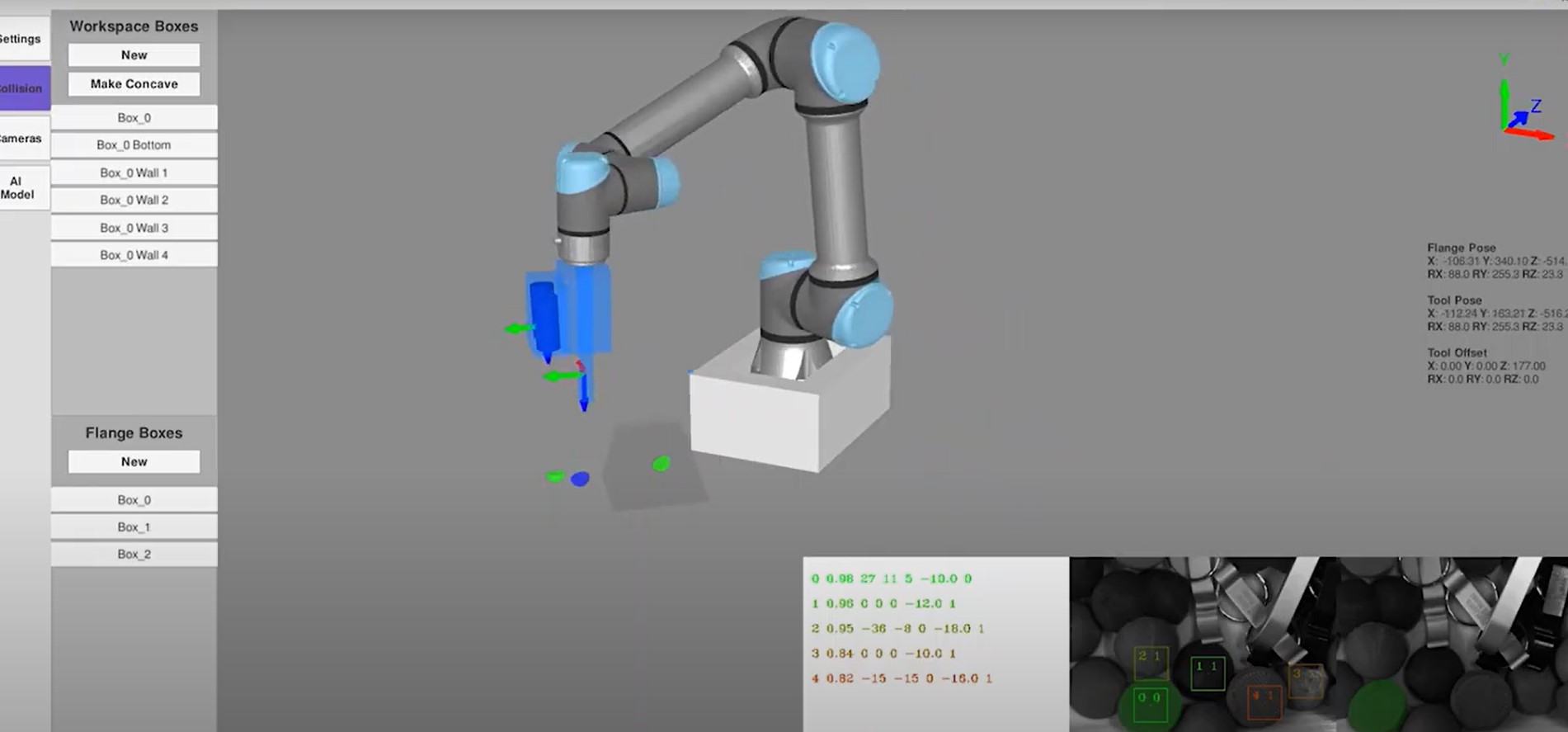

AI-supported processes

Traditional image processing reaches its limits with varying objects or difficult surfaces. This is where AI algorithms supplement recognition by learning from sample data.

- Training on real product images to develop robust models

- Detection even with low contrast, wear or surface variations

- Combination with 2D or 3D systems possible

- Typical application: Detection of asymmetrical, deformed or strongly varying components

The CHROMOS way to the optimum solution

Needs analysis and advice

Together, we clarify which parts are handled, how they are available and what accuracy is required. This enables us to narrow down the appropriate technology at an early stage.

Test setup with real products

In practical tests, we check how robustly the detection of position and orientation works under real light and environmental conditions.

Integration into the robot control system

Our systems supply the determined data to the robot in real time. Interfaces to control systems and peripherals ensure a seamless process.

Support and further development

With local service and training, we ensure that your solution works reliably in the long term - even with new components or process changes.

Contact us

Our experts will be happy to help you. Get in touch with us!