Label tubular bags

Reliable labeling for horizontal and vertical pouch solutions - directly integrated into your packaging line.

Tubular bag packaging is the preferred solution in many industries - from food and pharmaceutical products to everyday consumer goods. They enable efficient, flexible and product-friendly packaging with high line output.

Tubular bags are usually marked directly on the packaging line - often at high speed and on sensitive, non-absorbent surfaces. This places special demands on positioning, legibility and synchronization with the packaging process. Changing formats or product batches must also be marked reliably and traceably.

Get in touch with usWhy is the labeling of tubular bags important?

Ensure traceability

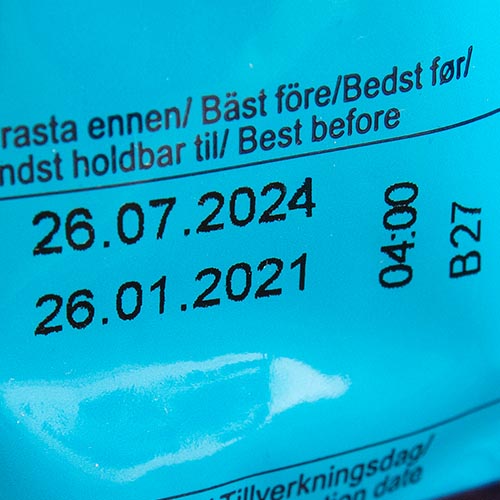

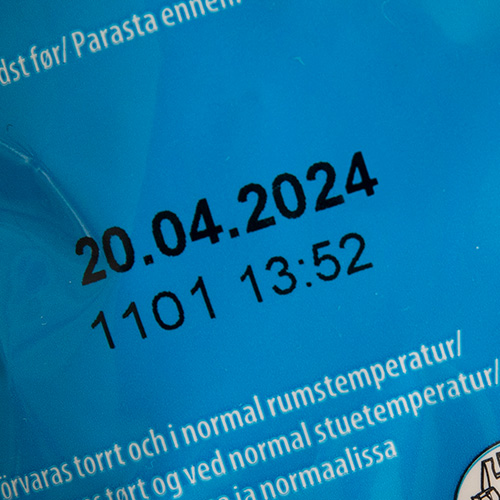

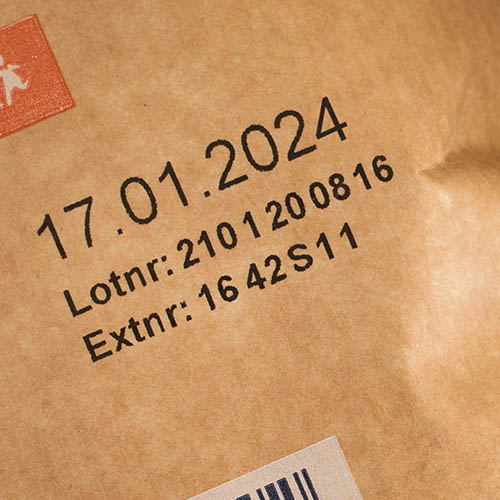

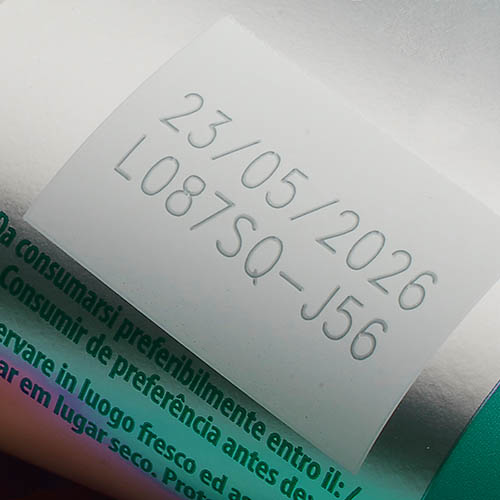

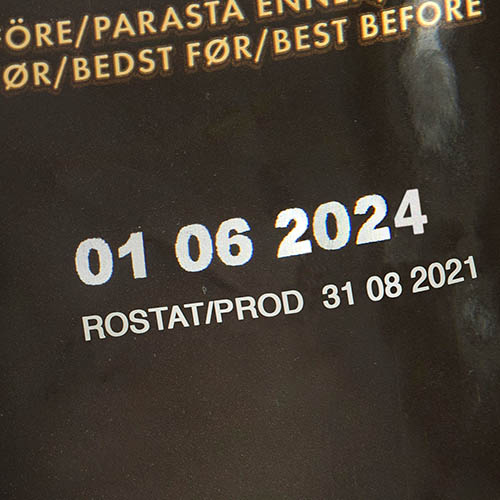

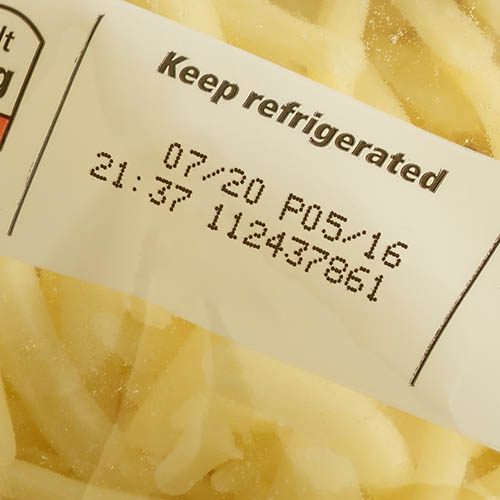

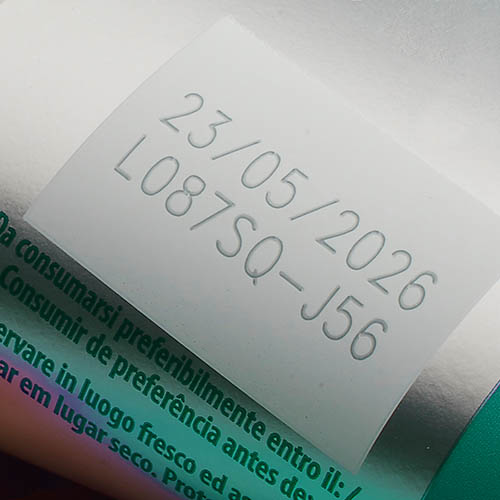

Batch and production data are required by law for many applications - especially for food and pharmaceutical products. Clear and permanent labeling is the basis for recall management, quality assurance and transparency along the supply chain.

Placing consumer information

Variable information such as best-before date, manufacturer information or production times must be clearly legible on the pouch - even with high cycle rates and changing product formats.

Synchronize processes

As pouch packaging often takes place in a continuous or synchronized process, the marking must be precisely coordinated with the packaging process - both mechanically and in terms of data. This is the only way to ensure stable, reliable marking.

Challenges in the labeling of tubular bags

Packaging on flow-wrapping machines involves special technical requirements - depending on speed, material and line concept:

Movement & Timing

Tubular bags often run in a continuous or intermittent process, which makes it difficult to position the marking. The print must be synchronized with the bag movement - without contact and without slowing down the line.

Material & surface finish

Many bags are made of smooth, coated or lubricant-treated films that are difficult to print on. Nevertheless, the marking must be smudge-proof, high-contrast and permanently legible - even in damp or thermally demanding environments.

Product variety & format change

The bag size, fill level or batch identification varies depending on the application. The marking solution must react flexibly to changing formats - often in conjunction with variable data such as date, code or product number.

Suitable technologies

The selection of the right marking technology for tubular bags depends heavily on the type of packaging, the material properties and the line speed. Three processes in particular have proven themselves in practice:

Get in touch with us

Thermal transfer printing (TTO)

Thermal transfer printing is integrated directly into the flow-wrapping machine - usually with intermittent or continuous film systems. TTO enables sharp print images directly on the film, e.g. best-before dates, batches or codes.

Particularly suitable for:

- Vertical or horizontal flow-wrapping machines

- Film packaging with a smooth surface

- Precise pressure positioning at standstill or in motion

Continuous Inkjet (CIJ)

CIJ systems mark tubular bags without contact and are particularly suitable for high-speed or moving applications. With specially formulated inks, even coated or lubricant-treated films can be reliably printed.

Particularly suitable for:

- Continuously running packaging lines

- Flexible print positions for changing formats

- Applications with high output and variable data

Laser

Lasers offer a consumable-free alternative, especially for coated or thermally activated films. They create permanent markings by ablation or color change without damaging the packaging.

Particularly suitable for:

- Applications with high line speed

- smudge-proof coding without ink

- Hygienically sensitive production environments

The CHROMOS way to the optimum solution

Understanding the application

Together we analyze your packaging line - whether vertical or horizontal flow-wrapping machine - as well as material properties, process conditions and requirements for readability, cycle time and data content.

Suggest technology and implementation

Based on your specific application, we show you suitable technologies and integration options - tailored to line speed, material routing and the right time for labeling.

Check feasibility

We test print quality, positioning and durability in practical trials - directly on your packaging materials and under realistic production conditions.

Support through to commissioning

From device selection to commissioning, we accompany you with technical expertise, training and support - so that the marking fits smoothly into your line.

Our tip: Get advice from our experts

Not every tubular bag is the same - and not every marking technology is suitable for every material, packaging process or product format.

We help you to find the right process for your production line and your packaging - high-contrast, reliable and permanently legible.

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!