Laser marking

Precise marking of all materials - efficient, durable and sustainable

Laser marking stands for maximum precision and reliability in industrial marking. Whether on metals, plastics, glass or organic materials - modern laser technology enables long-lasting and sustainable markings that are characterized by accuracy and durability. Flexibility and efficiency make laser marking an indispensable technology for numerous industries.

Get in touch with usAdvantages of laser marking

Precise

Markings with maximum accuracy

Sustainable

Without consumables.

Permanent

Resistant to environmental influences

Versatile

Suitable for almost all materials.

Cost-efficient

Reduces operating costs

Fast

Ideal for high speeds

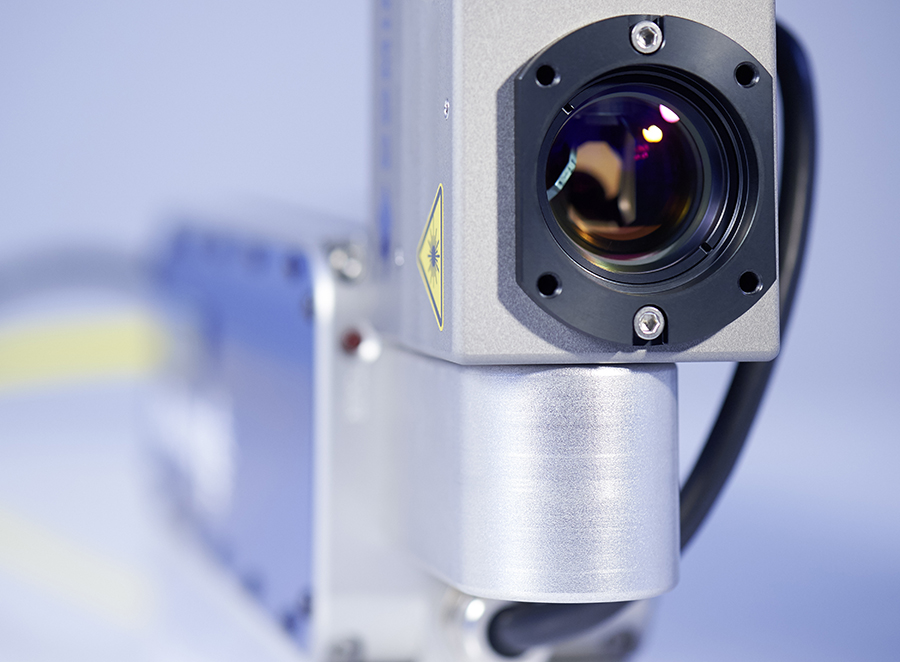

Laser technologies at a glance

Laser marking systems offer diverse solutions for a wide range of materials and applications. From metals and plastics to flexible packaging - each laser technology has its specific strengths and areas of application. We present the three main technologies below: Fiber lasers, CO2 lasers and UV lasers.

Fiber laser

How does a fiber laser work?

A fiber laser generates its beam in a glass fiber core and guides it to the processing location via light guides. This technology is energy-efficient and ideal for precise markings on hard materials such as metals.

Areas of application and advantages

Particularly suitable for the laser marking of aluminum and tinplate cans in the food and beverage industry, e.g. for best-before dates or batch numbers.

- Durable markings: Resistant to heavy use.

- High precision: Easy-to-read codes on small surfaces.

- Efficient: Reliable at high production speeds.

CO2 laser

How does a CO2 laser work?

CO2 lasers work with infrared radiation (10,600 nm), which specifically triggers thermal reactions on the surface of a material. The effect of the heat leads to permanent marking through vaporization, foaming or discoloration. This technology is particularly suitable for organic materials and offers reliable results at high production speeds.

Areas of application and advantages

CO2 lasers are particularly suitable for packaging materials such as cardboard, paper, glass and plastics. Thanks to their efficiency, precision and versatility, they are an established solution in numerous industries.

- Variety of materials: Suitable for paper, cardboard, PET, glass, wood and many plastics.

- High precision: Clear markings even with small codes and high speeds.

- Cost-effectiveness: No consumables, low maintenance.

- Sustainability: Environmentally friendly thanks to emission-free, contactless marking.

UV laser

How does a UV laser work?

UV lasers work with ultraviolet wavelengths (355 nm), which trigger a photochemical reaction in the uppermost material layer. In contrast to other laser types, the UV laser does not remove any material, but changes the surface gently and without thermal stress.

Areas of application and advantages

UV lasers are particularly suitable for sustainable packaging materials such as monofilms, colored and white plastics and medical products. They deliver precise, high-contrast results without damaging the material.

- Material protection: Reliable marking without eroding or impairing the barrier properties.

- Highest precision: Perfect for filigree codes with a beam diameter of 30 µm.

- Versatility: Suitable for packaging made of PE, PP and flexible films.

Comparison of the different laser marking technologies

| property | Fiber laser | CO2 laser | UV laser |

| Functionality | Beam from fiber optic core, transmitted via optical fiber | Jet of excited gas mixture (carbon dioxide) | Beam by frequency doubling for ultraviolet wavelengths |

| Wavelength | 1064 nm | 10.6 µm | 355 nm |

| Material removal | Yes, material is removed by high energy | Yes, especially for packaging materials | No, material is changed gently |

| Input materials | Metals, hard plastics, ceramics | Paper, cardboard, wood, glass, plastics | Thin monofilms, colored/white plastics, glass, medical products |

| Typical applications | Can labeling (F&B), long-life barcodes, serial numbers | Marking of packaging, labels and cartons | High-contrast codes for flexible packaging and medical technology |

| Thermal load | High | Medium | Low |

| Marking precision | High | Medium | Very high |

| Speed | Very high | High | Medium |

| Special features | Robust, ideal for demanding industrial environments | Versatile and cost-efficient for packaging materials | High precision without additives, ideal for thin, flexible materials |

Laser technology in action - a look inside the Domino laser lab

Experience how customer samples are analyzed and tested for individual requirements in the Domino laser laboratory in Hamburg. Our team of experts develops tailor-made laser solutions that guarantee maximum precision and efficiency.

Domino Extrusion Laser Coding Station

Special laser marking solution for pipes, cables and other extruded products

The Domino Extrusion Laser Coding Station is a solution for the precise marking of pipes, cables and other extruded products. This solution has been specially developed for the requirements of the extrusion industry and provides accurate markings even at high speeds.

The station is compatible with the Domino D-Series (CO2 lasers) and F-Series (fiber lasers), so that a wide range of materials can be marked reliably and efficiently.

Find out more about the Extrusion Laser Coding Station

Contact us

Our experts will be happy to help you. Get in touch with us!