Domino Gx Series | Thermal Inkjet Printer (TIJ)

Clean and precise coding with low-maintenance thermal inkjet printers

The Domino Gx series stands for high-precision thermal inkjet printers (TIJ) that produce razor-sharp and durable markings on a wide range of materials. With a resolution of up to 600 dpi and print speeds of up to 300 m/min, the printers are suitable for demanding applications in industries such as pharmaceuticals, electronics and consumer goods. Thanks to flexible printhead options, easy integration and minimal maintenance, the Gx printers meet the highest demands for quality and efficiency - even in complex production processes.

- Excellent print quality: resolutions up to 600 dpi for sharp codes, text and graphics.

- High speed: Print speeds of up to 300 m/min for fast production lines.

- Flexibility: Printhead options for different requirements, including multi-line printing.

- Easy integration: Compact and compatible with Industry 4.0.

- Virtually maintenance-free: AutoSwap cartridge change for uninterrupted operation.

Domino Gx150i

Compact TIJ printer for precise coding

The Gx150i is the ideal introduction to thermal inkjet technology (TIJ) and offers precise and reliable coding for batch, date and time information. With a resolution of up to 600 dpi and print speeds of up to 300 m/min, the printer delivers razor-sharp codes on materials such as cardboard, film, plastic and metal. Its compact design and flexible print head options allow for easy integration into existing production lines. The intuitive touchscreen user interface makes operation particularly user-friendly, while the AutoSwap function allows cartridges to be changed during operation without interrupting production.

Domino Gx150i brochure

Domino Gx350i

Versatile TIJ printer for demanding applications

The Gx350i combines flexibility and performance to handle even complex coding tasks. It can control up to four print heads, allowing a print height of up to 50.8 mm or individual coding in multiple positions. With a resolution of up to 600 dpi and speeds of up to 300 m/min, the printer delivers reliable results, whether for multi-line text, barcodes or graphics. The robust design and Industry 4.0 compatibility make it a future-proof solution for demanding production environments, such as in the pharmaceutical, consumer goods or electronics industries. The Gx350i supports numerous data protocols and enables simple remote monitoring via the Domino Cloud.

Domino Gx350i brochureDomino Gx-OEM

Especially for integration into production systems

The Gx-OEM is a specially developed solution for seamless integration into production systems. Its modular design allows the operation of up to four print heads, which can be used for flexible coding requirements at different positions or for higher print heights. The controller is optimized for installation in control cabinets and the print head can be installed up to 25 meters away. With a resolution of up to 600 dpi and fast-drying inks, the Gx-OEM prints precise and durable codes even on demanding substrates. Its AutoSwap function and Industry 4.0 compatibility make it the preferred choice for OEM applications in serialization, track & trace and quality control.

Domino Gx-OEM brochure

Suitable for the following applications

Fast-moving consumer goods

The Gx series offers precise and reliable coding for the consumer goods industry (FMCG). With a comprehensive range of inks, it is ideal for flexible films, porous packaging and shelf-ready shipping cartons.

Life sciences

The Gx series meets pharmaceutical requirements, including GS1 standards and the EU Falsified Medicines Regulation (2016/161). It is also optimized for use in validated 21 CFR Part 11 systems.

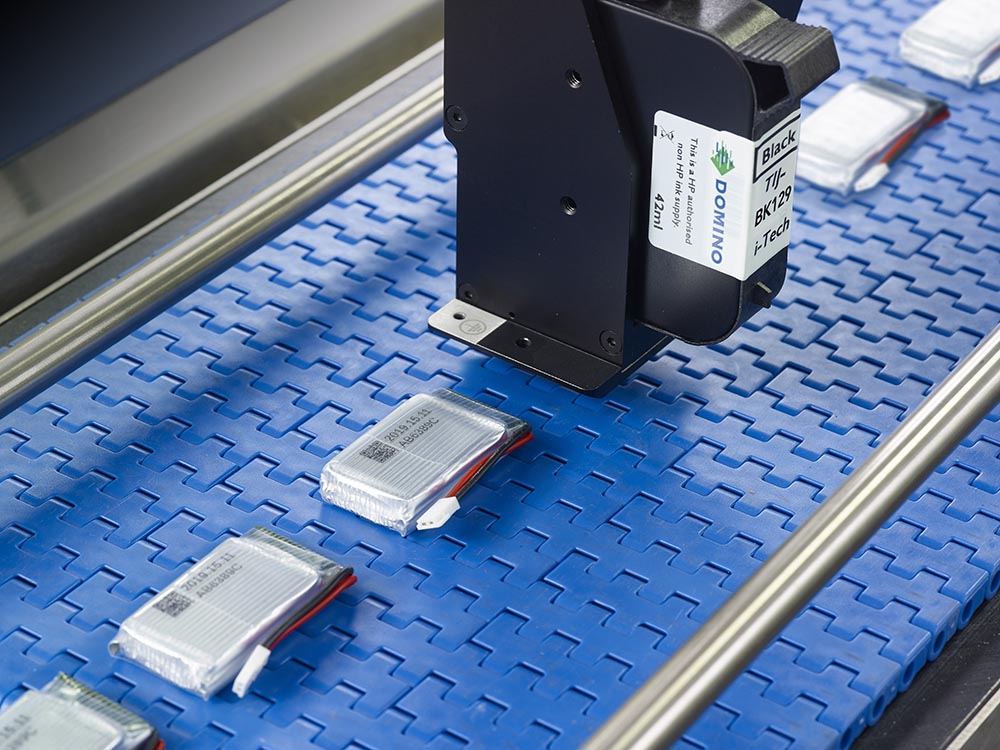

Industry and electronics

The Gx series ensures fast production lines with short drying times and abrasion-resistant coding. It delivers long-lasting and precise results on a wide range of materials.

Feature comparison of the Domino Gx series thermal inkjet printers (TIJ)

| Feature | Gx150i | Gx350i | Gx-OEM |

| Field of application | Precise coding for basic applications | Versatile applications with higher requirements | Integration in packaging systems for OEM solutions |

| Print resolution | Up to 600 dpi | Up to 600 dpi | Up to 600 dpi |

| Print speed | Up to 300 m/min | Up to 300 m/min | Up to 300 m/min |

| Number of print heads | 1-2 printheads | Up to 4 print heads | Up to 4 print heads |

| Maximum pressure height | Up to 12.7 mm | Up to 50.8 mm | Up to 50.8 mm |

| Integration | Compact and easy to integrate | Supports complex lines with multiple print positions | Modular design for control cabinets, controllers up to 25 m away |

| User interface | 7-inch touchscreen | 10-inch touchscreen | Can be controlled via the HMI of the production line |

| Special features | AutoSwap for uninterrupted operation | Industry 4.0 compatibility, remote monitoring | OEM-optimized for serialization applications |

Video about the Domino Gx series

How thermal inkjet technology works

Thermal inkjet technology (TIJ) is based on a precise and contactless printing process in which ink is applied to the substrate using heat and pressure. A tiny drop of ink is generated in each nozzle of the print head by a short heat pulse and shot onto the material. This process enables razor-sharp, high-resolution prints with a resolution of up to 600 dpi.

A key advantage of TIJ technology is its speed: production lines can reach speeds of up to 300 m/min without compromising on print quality. Thanks to the clean handling of the cartridges and the fast drying time of the ink, TIJ is ideal for various materials such as plastic, cardboard, flexible films and metal.

In addition, TIJ technology is virtually maintenance-free. The integrated print head in each cartridge eliminates the need for cleaning, and cartridges can be changed on the fly with the AutoSwap function. These features make the Gx series an efficient and reliable solution for industries with high demands on precision and speed.

Contact us

Our experts will be happy to help you. Get in touch with us!