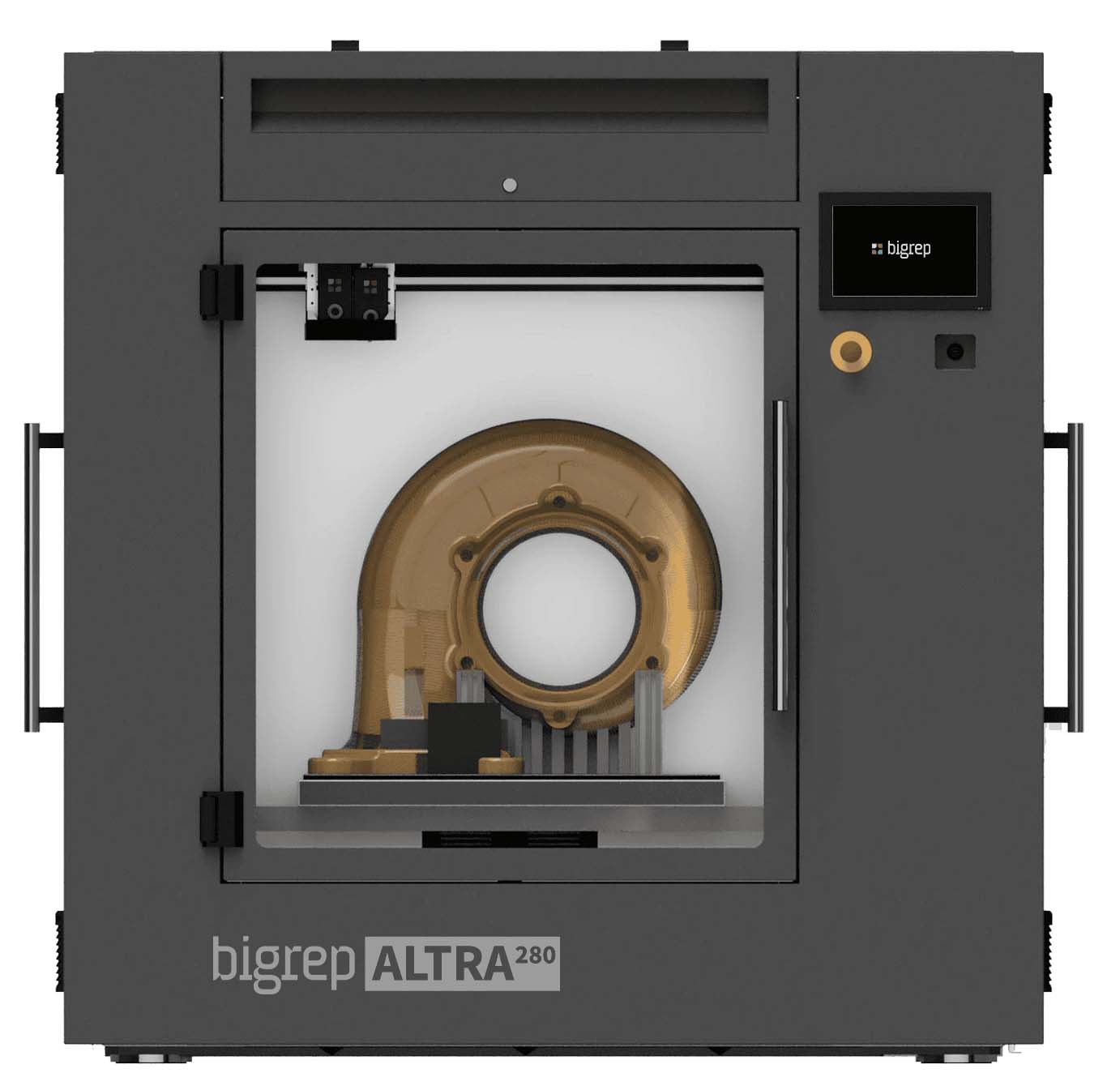

BigRep ALTRA 280

The ultimate 3D printer for high-performance applications

The BigRep ALTRA 280 is the most advanced industrial 3D printer designed specifically for demanding high-temperature applications. With an impressive build envelope of 500 x 700 x 800 mm and the ability to process a wide range of high-performance materials, the ALTRA 280 sets new standards in precision, speed and versatility. Equipped with the latest technology, including water-cooled multi-extruders, precise hotends and an intelligent monitoring function, this printer offers everything needed for the production of prototypes and end products.

- Large installation space: 500mm x 700mm x 800mm (x,y,z) for large format prints.

- High temperature capacities: extruder temperatures up to 450°C and build chamber temperatures up to 180°C, ideal for high-performance materials.

- Versatile material compatibility: Supports a wide range of BigRep and third-party materials such as ABS, ASA, PA12 CF and ULTEM 9085.

- Powerful extruders: Up to 4 water-cooled Direct Synchronized Extruders (DSX) for precise and efficient printing.

HIGH PERFORMANCE FOR EVERY INDUSTRY

Aerospace parts

Innovative and certifiable parts for the aerospace industry. The ALTRA 280 prints with high-performance materials and creates strong, safe and lightweight parts. The high precision, repeatability and resolution enable innovation at all stages of the design process.

Functional prototypes

Test designs and validate parts before they go into final production. The open material system gives you the freedom to choose from a variety of filaments and accurately replicate the final part. Iterate faster, reduce manufacturing costs and get your products to market faster.

Durable tools

Produce cost-effective, fast tools for your production, such as jigs and fixtures. Thanks to high-temperature capabilities, you can produce strong and geometrically complex tools in-house. Overcome outdated traditional techniques and print tools on demand.

| Version | BigRep ALTRA 280 |

|---|---|

| Installation space | 500mm x 700mm x 800mm (x,y,z) |

| BigRep materials | ABS, ASA, BVOH, HI-TEMP, HI-TEMP CF, PA12 CF, PA6/66, PETG, PLA, PLX, PRO HT, TPU 98A |

| Compatible materials | ABS, ABS-ESD, ABS-FR, ASA, HT-PETG, PA6, PA6-CF, PA12, PA12-CF, PA12-GF, PC, PC-ABS, PC-FR, PC-CF, PCTG, PEKK, PEKK-CF, PETG, PLA, PP, PP-GF, PPS, PPSU, TPU, TPC, ULTEM 9085 (open for third-party materials) |

| Extruder | Direct Synchronized Extruder (DSX) |

| Extruder configuration | Multi-DSX water cooling (up to 4 extruders) |

| Hotends | Precise, Power or High Flow |

| Nozzles | Brass or hardened steel |

| Nozzle diameter | 0.4mm, 0.6mm, 1.0mm |

| Layer thickness | From 0.05mm |

| Extruder temperature | Up to 450°C |

| Building chamber temperature | Up to 180°C |

| Print bed temperature | Up to 180°C |

| Maximum print speed | Up to 350 mm/s |

| Maximum throughput | Up to 250 g/h |

| Position accuracy | < 0.05mm in XY |

| Speed of movement | XY~400 mm/s |

| Drive technology | Servo motor in XYZ |

| Air purification unit | Filter system with activated charcoal filter and HEPA filter |

| Safety circuit | Unmanned 24/7 operation |

| Connectivity | USB, network |

| Pressure interruption | Filament sensor with intelligent 'Stop and Go' function (build chamber and print bed remain heated) |

| Slicing software | Simplify3D, others available on request |

| Machine control | HAGE3D industrial controller |

| HMI | LED + 12.1" touchscreen |

| Camera | Wide-angle HD color camera for real-time remote monitoring |

| Override function | Manual override in real time |

| User access | Multi-level user authorizations |

| Power supply | 400 V / 32 A |

| Dimensions | 2550mm x 1950mm x 1920mm (x,y,z) |

| Weight | Approx. 1980kg |

Contact us

Our experts will be happy to help you. Get in touch with us!