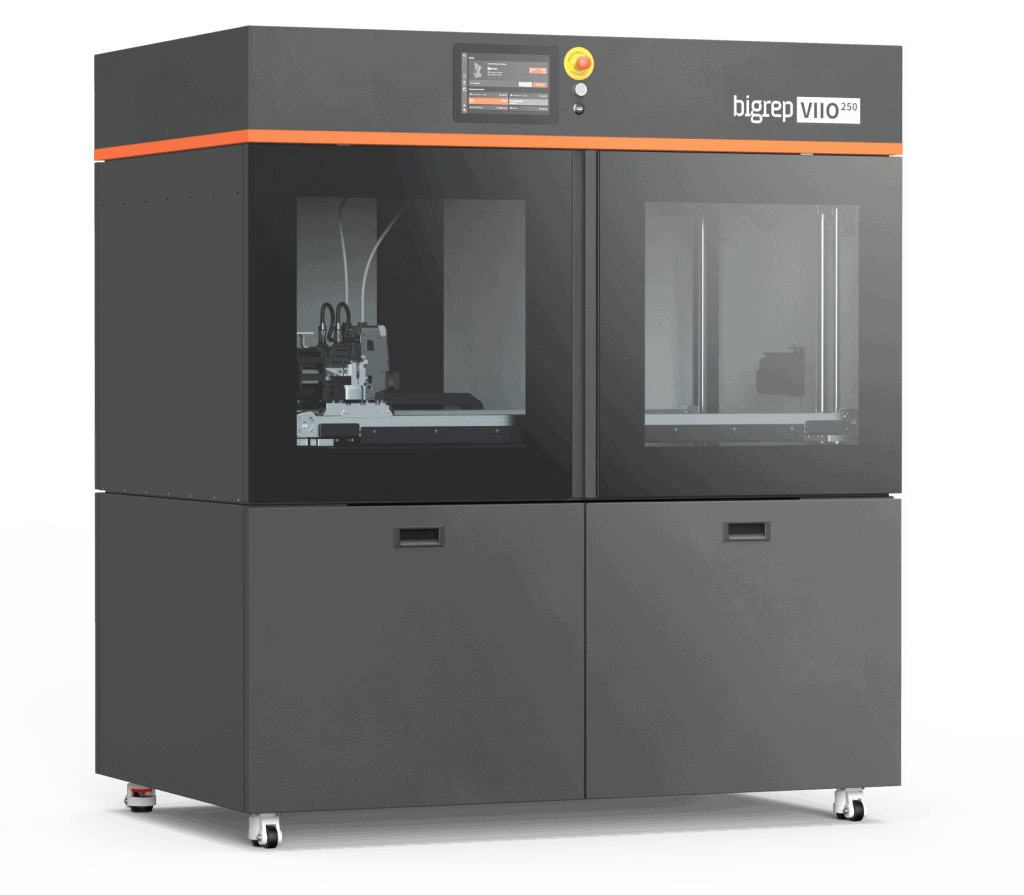

BigRep VIIO 250

A new standard for automated production

The BigRep VIIO 250 is a fully automated 3D printer for continuous, reliable industrial production. Equipped with innovative automation functions, such as the relay mode, in which an extruder serves as a backup, it sets new standards in large-format FFF printing. Print bed calibration and sequential printing of components are automated, and filament handling is handled by the integrated Infinity Box. Two Smart Manufacturing extruders and an intuitive user interface with animated instructions facilitate operation.

The VIIO 250 enables efficient and cost-effective production of functional parts with low energy consumption. Print faster and save time and costs by maximizing machine efficiency.

- 250 liter installation space: Heated up to 50° C

- Dual DSX extruder: For high precision and speed

- 3D printing of technical materials: at up to 350° C

- Maximum efficiency: automation for uninterrupted operation

HIGH PERFORMANCE FOR EVERY INDUSTRY

Automotive parts

Produce durable parts for a range of applications in the manufacturing industry. The VIIO 250 prints with engineered materials and produces strong, lightweight parts. The high accuracy, repeatability and resolution enable innovation at all stages of the design workflow.

Functional prototypes

Test designs and validate parts before they go into final production. The open material system gives you the freedom to choose from a variety of filaments and accurately replicate the final part. Iterate faster, reduce manufacturing costs and get your products to market faster.

Durable tools

Produce cost-effective, fast tools for your production, such as jigs and fixtures. Thanks to high-temperature capabilities, you can produce strong and geometrically complex tools in-house. Overcome outdated traditional techniques and print tools on demand.

| Version | BigRep VIIO 250 | |

|---|---|---|

| Installation space | 1000 mm x 500 mm x 500 mm (x,y,z) | |

| Compatible materials | BigRep ASA, BVOH, HI-TEMP, HI-TEMP CF, PA12 CF, PA6/66, PETG, PLA, PLX, PRO HT, TPU 98A (open for third-party materials) | |

| Support materials | BigRep BVOH (open for third-party materials) | |

| Diameter of the filament | 2.85 mm | |

| Extruder | Dual Smart Manufacturing Extruder (SMX) | |

| Nozzles | Tungsten carbide (0.4 mm, 0.6 mm) or polycrystalline diamond (1.0 mm) | |

| Nozzle diameter | 0.2 mm, 0.3 mm, 0.6 mm | |

| Layer thickness | 0.2 mm, 0.3 mm, 0.6 mm (other layer thicknesses are supported by slicer software) | |

| Extruder temperature | Up to 350 °C | |

| Installation space temperature | 30-50°C | |

| Print bed temperature | Up to 120 °C | |

| Removable pressure bed surface | SWITCHPLATE prime, SWITCHPLATE select | |

| Maximum print speed | Up to 200 mm/s | |

| Maximum throughput | g/h (115 cm³/h) with PLA | |

| Position accuracy | ±0.2 mm ±0.002 mm/m in XY, ±0.1 mm ±0.001 mm/m in Z | |

| Drive technology | Stepper motors with steel-reinforced belt drive in XY, spindle with self-lubricating nut in Z | |

| Interfaces | 10/100/1000 Base T Connection Ethernet Protocol, USB port, BigRep Connect Ready with remote monitoring and control functions | |

| Slicer software | BigRep BLADE | |

| Machine control | BigRep crossboard | |

| HMI | 12.1" touchscreen | |

| Camera | Integrated installation space camera for remote monitoring in real time | |

| Power supply | 208-240 V, 50/60 Hz, 16 A | |

| Power consumption | Average (during printing): 660 W, peak value: 3200 W | |

| Dimensions | 1715 mm x 1170 mm x 1765 mm (x,y,z) | |

| Weight | 560 kg 3D printer (basic equipment), 62 kg Infinity Box | |

Further information

Contact us

Our experts will be happy to help you. Get in touch with us!