With the comprehensive Sinterit powder tool set, you save material and working time during pre- and post-processing. At the same time, the work area is kept clean and tidy. The new powder tools can be used throughout the entire printing process: During commissioning, when removing the objects, as well as during post-processing and cleaning both the printed objects and the work area.

Sinterit Powder tool set

Special tools for the entire printing process

Secure workflow, clean working environment

The powder tool set complements the Sinterit accessories, such as the ATEX vacuum cleaner, and simplifies powder handling before and after the printing process.

The powder tool set consists of:

- Protective equipment (safety goggles, dust mask, T-shirt, protective gloves)

- Powder handling tools (scraper, ladle, brush, measuring cup)

- Tools for post-processing (large & small brushes, metal sieve, stainless steel probe & spatula)

- Service kit (bag, alcohol pads, silicone oil, cotton cloth, replacement recoater cord, infrared emitter)

- Powder container (IO box, powder box)

- Powder bucket with funnel

- Foldable collecting container or work surface

- Manual

More details

-

Powder funnel

The powder funnel enables the printer to be filled in a targeted manner without the powder getting into the air. The powder funnel can be placed on the new Sinterit powder material buckets. This means that the powder can be easily filled into the printer directly from the original powder bucket. The powder funnel is also compatible with the Sinterit sieve and the powder separator in the ATEX vacuum cleaner.

-

Powder spatula

The Sinterit powder spatula has been redesigned so that it fits on the surface of the entire print bed. As a result, the powder can now be better distributed and evenly pressed in a single pass. This ensures even powder distribution and density for successful SLS printing.

-

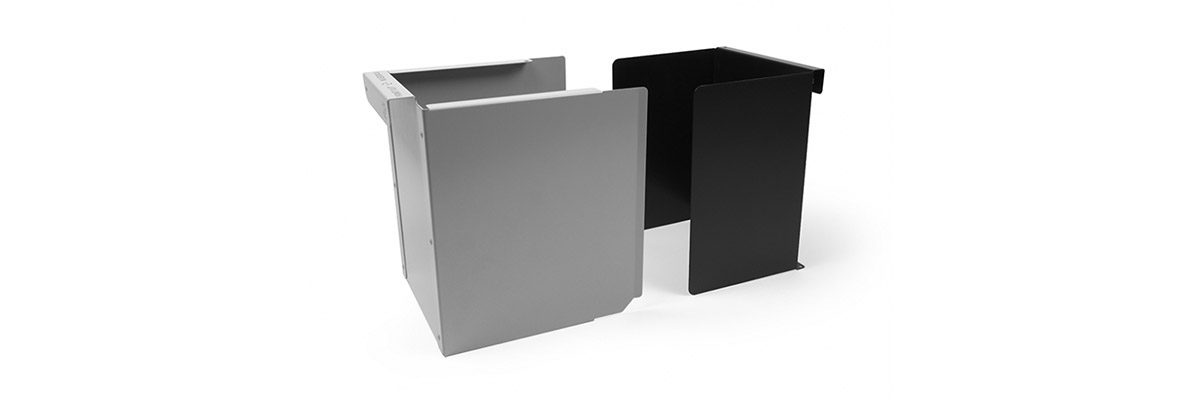

IO-Box

Filling the Sinterit printers is even more precise with the IO BOX. The Sinterit IO box consists of two metal elements that serve as a guide to pour in the powder without scattering it and contaminating the pyrometer or other parts of the printer. The IO box is used both for filling the printer and for removing the finished printout from the printer and transporting it quickly and safely to the post-processing area.

-

Foldable work surface

It is a container with foldable edges that offers optimum working space for the initial post-processing of the print objects. The parts can be easily vacuumed and the residual powder can simply be poured into a bucket for further cleaning and print preparation.