Sinterit Lisa X

The open SLS 3D printer for industrial applications

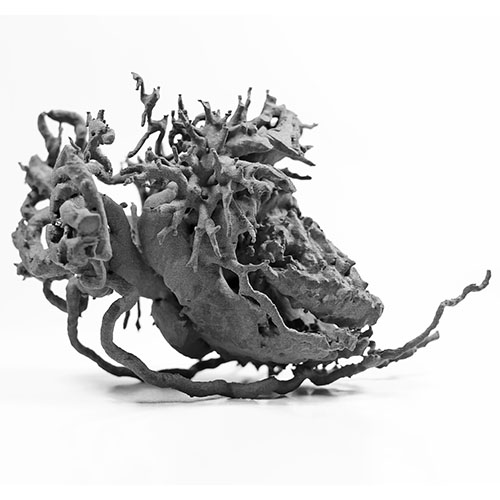

The Lisa X is the most powerful compact SLS 3D printer from Sinterit - with open architecture, industrial printing speed and large installation space. It was developed for companies that want to combine maximum flexibility, material diversity and production reliability in one system.

from CHF 21'990.00

Main features:

- Open system with freely adjustable pressure parameters

- Large installation space: 130 × 180 × 330 mm

- Fast printing: up to 14 mm/h

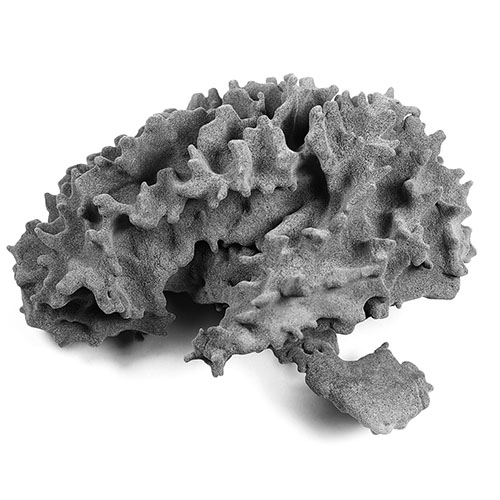

- Wide material compatibility, incl. PA12, PA11 CF, ESD, TPU and PP

- Industry 4.0 ready - API & system integration

- ATEX-certified complete system (in the Performance Set)

The Lisa X combines industrial performance, material freedom and compact efficiency - ideal for development, production and research.

Get in touch with us| Feature | Details |

|---|---|

| Laser type | 30 W IR fiber coupled diode laser (λ = 976 nm), galvo-controlled |

| Layer thickness | 0.075 - 0.175 mm |

| Max. construction volume | 130 × 180 × 330 mm (PA/PP) / 130 × 180 × 340 mm (TPU) |

| Print speed | up to 14 mm/h |

| Temperature zones | 4 heating zones with 22 heating elements |

| Inert gas control | integrated |

| Dimensions | 650 × 610 × 1200 mm |

| Weight | 145 kg |

| Average power consumption | 0.85 kW |

| Max. Power consumption | 1.65 kW |

| Software | Sinterit Studio (Basic / Open) |

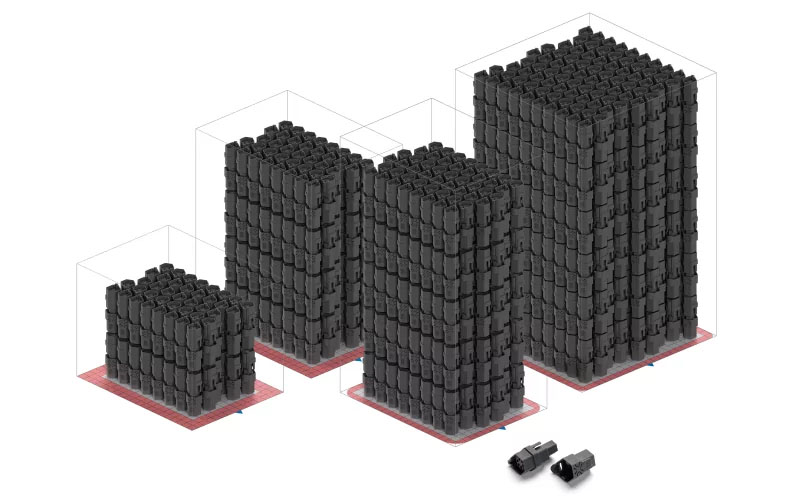

Small series production made easy

Thanks to its high printing speed and large installation space, the Lisa X is not only suitable for individual parts, but also for the series production of small quantities. The consistent repeat accuracy, simple file management in Sinterit Studio and the option of remote monitoring make it the ideal solution for production-related applications.

Particularly suitable for:

- Functional prototypes and pilot series

- Spare parts with short delivery times

- Repeatable small batches

- In-house production with high flexibility

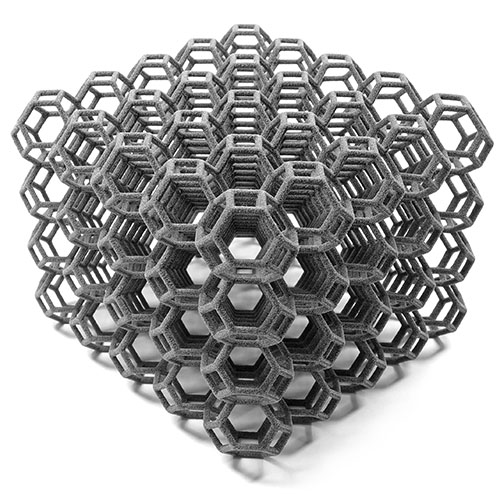

Open system for maximum control

The Lisa X provides access to all relevant printing parameters - including temperature zones, scan settings and cooling phases. This makes it ideal for anyone who wants to test their own materials, optimize existing ones or conduct scientific work. Whether research, development or material comparisons - with Lisa X you remain independent and flexible.

- Four individually adjustable heating ranges

- Customizable scanning & cooling parameters

- Ideal for third-party materials and own material developments

- Supports complex print profiles and test series

Reliable in daily use

With its robust design, ATEX certification (included in the set) and sophisticated operating concept, the Lisa X is made for continuous operation. Maintenance and powder management can be carried out efficiently, the software is intuitive - and the support network is available if required. For anyone who wants to print every day without having to solve problems every day.

This is what Lisa X stands for:

- ATEX-certified installation space (in set)

- Intuitive operation with Sinterit Studio

- Network & API integration

- Maintenance-friendly system design

Lisa X Starter Pack

The entry into the world of open SLS printing - compact, powerful and ready for immediate use.

Included:

- Lisa X 3D printer (230V)

- Sinterit Studio Advanced Software

- Dedicated Powder Tools

- Flight Case Lisa X / SUZY

- Consumables Kit Lisa X

Lisa X Performance Set

Additional tools for screening & manual post-processing - ideal for beginners with practical requirements.

Included:

- Lisa X 3D printer (230V)

- Sinterit Studio Advanced Software

- Multi PHS (powder handling)

- ATEX Vacuum Cleaner

- Sandblaster SLS

- Powder Separator

- Dedicated Powder Tools

- Consumables Kit Lisa X

- Flight Case Lisa X / SUZY

Set components explained

Multi PHS

Multifunctional powder handling station for low-dust processing and recovery of powder material. Ideal for removal, cleaning and recycling after the printing process.

Sandblaster SLS

Universal blast cabinet for surface treatment and powder removal using glass beads. Removes powder residue from printed parts efficiently and precisely.

ATEX Vacuum Cleaner

Certified industrial vacuum cleaner for safe powder recovery and cleaning. With high suction capacity and HEPA filter for maximum safety in the working environment.

Dedicated Powder Tools

Essential tool set for the safe handling of powder and the manual reworking of components.

Sinterit Studio Software

Intuitive 3D printing software for auto-nesting, slicing and flexible print profile adjustments. Part of every Sinterit.

Sinterit Powder Sieve

Compact sieve system for processing used powder batches - removes lumps and optimally prepares the material for the next print.

Video: The SLS workflow with the Lisa X - compactly explained

How does an industrial SLS printing process actually work? In this video, you will experience the individual steps with the Lisa X - from file upload and printing to powder recovery and post-processing.

The complete workflow with the Lisa X gives you a practical insight into:

- the processes and function of a professional SLS printer

- handling powder, installation space and printed parts

- the most important stations for clean, reproducible results

- the material cycle and the efficient reuse of powder

Ideal for anyone who wants to experience the Lisa X system in action and understand the SLS process in its entirety.

Contact us

Our experts will be happy to help you. Get in touch with us!