eviXscan 3D WideRange 65

High efficiency and accuracy when scanning large objects

The eviXscan 3D WideRange 65 scanner was designed for precise quality control of large elements (from 300 to 1200 mm [12″ to 47″]) in the shortest possible time. The WideRange 65 requires only 1.2 seconds for a single 3D scan. With a scan area of 575 x 290 x 240 mm [22.5″ x 11.5″ x 9.5″], it reduces the number of scans required to capture the shapes and dimensions of large parts. The high resolution of the cameras (8.9 Mpix) enables exceptional scanning results over a large area. The WideRange 65 offers a density of scan points of 54 pts/mm² and its accuracy reaches 0.03 mm (parameter Ps according to the guideline VDI/VDE 2634 part 2).

The possibility of its easy integration with a collaborating robot enables full automation of the scanning process. Minimizing the number of scans required during inspection is an important factor for production lines where time for scanning and generating a QC report is limited. The WideRange 65 is a perfect tool for quality control applications, reverse engineering and rapid prototyping of larger parts.

Features

- Outstanding scan quality and precision with a large working field

- Fast capture of scan data

- Easy integration with robots and collaborative robots

- Excellent price-performance ratio

Maximum efficiency and flexibility for industrial 3D scanning applications

Efficient recording for time-critical environments:

The WideRange 65 is optimized for fast 3D data acquisition, enabling a complete acquisition in just 1.2 seconds and increasing production output while minimizing downtime.

Robot integration for automated inspections:

With its adaptability, the WideRange 65 can be easily integrated into stand-alone and collaborative robot systems, increasing automation and ensuring consistent and efficient operations.

Wide range of applications:

Perfect for industries that require large object analysis, the WideRange 65 is ideal for the automotive, aerospace and industrial machinery sectors. For quality control, reverse engineering and rapid prototyping, it delivers precise results and provides comprehensive support for model reconstruction.

PRECISE AND FAST SCANS WITH A LARGE DETECTION RANGE

Areas of application for eviXscan 3D scanners

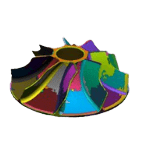

REVERSE ENGINEERING

The triangle mesh maps surfaces and forms the basis for creating CAD models of an object. This enables the creation of technical documentation for an object. The resulting model can be used to produce a replica or as a starting point for the design of new products or variants.

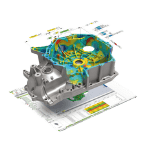

QUALITY CONTROL

The scanned product is compared to a CAD reference model to create color deviation maps that allow accurate verification of tolerances on production drawings and measurement of elements that are difficult to measure with other methods.

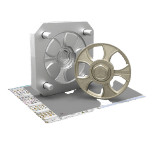

RAPID PROTOTYPING

The fast and cost-effective production of prototypes is now an important strategy for gaining a competitive edge. A precise 3D scanner, such as eviXscan 3D, is an essential part of the rapid prototyping process.

| Technical data: | eviXscan 3D Quadro + : |

|---|---|

| Measuring range | 575 x 290 x 240 mm |

| Dot density | 54 pt/mm² |

| Scan accuracy | 0.03 mm |

| Minimum scan time | up to 0.007 mm |

| Light source | Blue LED |

| Resolution of the cameras | 8.9 Mpix |

| Software | eviXscan 3D Suite |

| Computer connection | USB 3.0 |

| Export formats | stl, ply, obj, asc, bin |

| Operating system | Windows 10 (64 bit) |

| Hardware requirements | CPU i7, 32 GB RAM, NVMe SSD 480 GB |

Would you like to find out more?

Contact us

Our experts will be happy to help you. Get in touch with us!