Domino K600G

High-precision digital printing solution for variable data on blister packs

The Domino K600G is an advanced digital printing solution for variable data printing directly onto blister packs. Specifically designed to meet the needs of the pharmaceutical and medical device industries, it enables customized marking that ensures long-term brand protection and patient safety. Using the K600G increases the efficiency of your production, offers maximum flexibility for late stage customization and significantly reduces operating costs. With the K600G, you remain flexible with regard to legal requirements and can make adjustments directly in your production line.

- Increased efficiency: Improves production through fast and flexible adjustments

- Late Stage Customization: Individual marking directly on the production line.

- Easy integration: Seamless retrofitting and expandable functions.

- Cost reduction: Significantly reduces operating costs and operating time.

- High-quality printing: 600 dpi and up to 60 m/min ensure precise, variable data and graphics.

Configurations of the Domino K600G

The Domino K600G offers a range of configuration options that are perfectly tailored to the specific requirements of your production environment:

K600G Off-Line

The roll-to-roll solution works independently of your production line. After the printing process, the printed substrates can be integrated into your existing line to ensure flexible production handling.

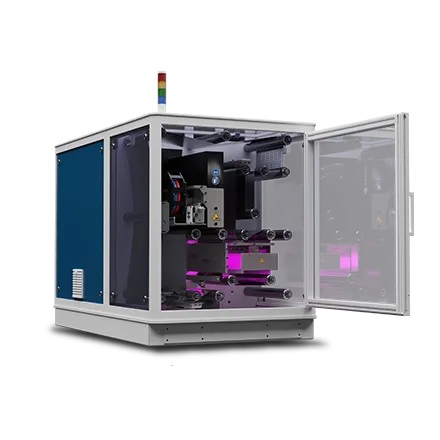

K600G Top-Of-Line Compact

This compact solution is integrated directly above your production line. It has a dancer arm system and a sensor that recognizes the interfaces of the blister film to enable precise printing.

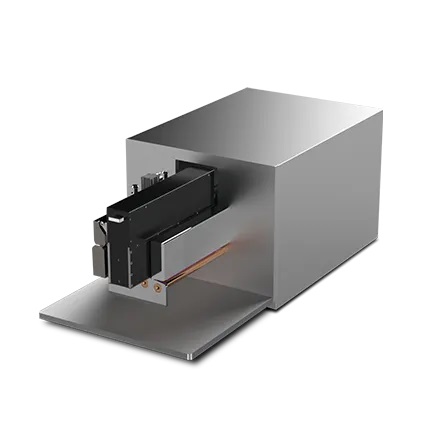

K600G Integrated Line

Developed for OEMs, the Integrated Line offers a compact and modular solution that fits seamlessly into existing production lines. Ideal for companies that require complete integration into their line processes.

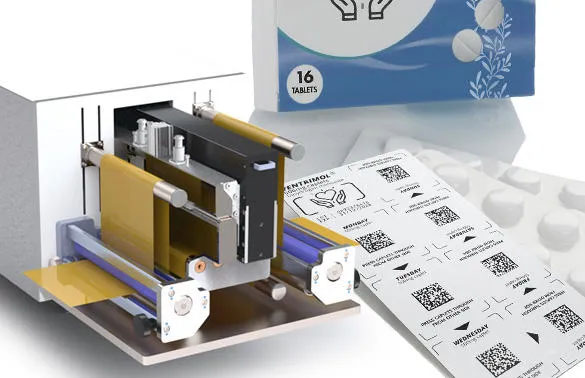

K600G Sealed Blister Coding Station (SBCS)

This station is perfect for the late customization of sealed blister packs. It offers flexibility and precision when marking packaging in the final phase of the production process.

Late Stage Customization (LSC)

The K600G supports Late Stage Customization (LSC), an ideal solution for companies looking to customize their packaging in the final stages of the production process. This is particularly valuable for the pharmaceutical industry, which often needs to respond to different market demands and regulatory changes. With LSC, packaging can be adapted at short notice, reducing the need for large stocks and minimizing the risk of outdated packaging.

Get in touch with us

Now and in the future

Reliability and durability are decisive factors in pharmaceutical production. When developing the K600G, the focus was not only on user-friendly integration into the production chain, but also on maximum protection for patients and brands. Pharmaceutical manufacturers and end users benefit from this innovative technology in the long term.

By using the K600G, pharmaceutical companies gain more independence from external packaging providers. This allows them to react more flexibly and quickly to legal changes in the labeling regulations of the life sciences industry.

Get in touch with us

Domino K600G - The perfect solution for blister packaging

Further information

Contact us

Our experts will be happy to help you. Get in touch with us!