Metal 3D printer

Industrial systems for prototypes, research and small series production

Metal 3D printing enables the fast, tool-free production of functional components - directly from digital design data. Whether in material development, prototyping or series production: with various printing technologies and system sizes, the requirements of a wide range of applications can be covered in a targeted manner. CHROMOS supports you with sound advice, technical solutions and proven systems for professional metal 3D printing.

Get in touch with usMetal 3D printer from Desktop Metal

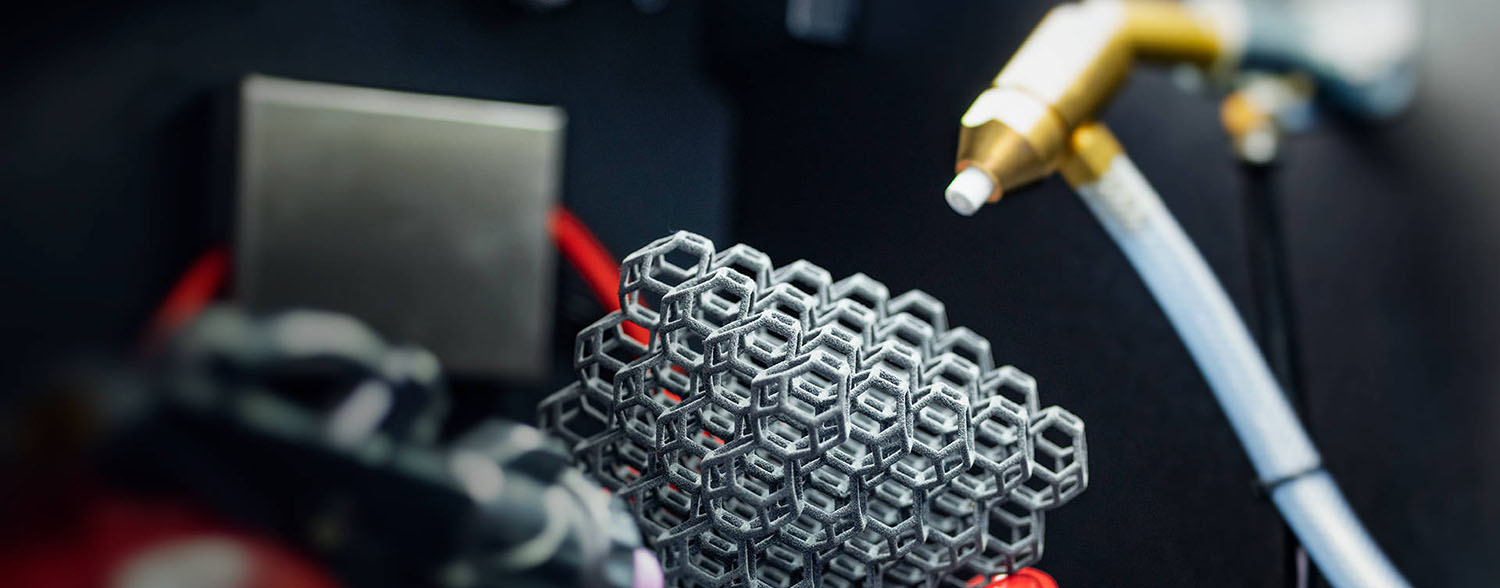

Desktop Metal 's systems cover a wide range of applications - from the workshop-friendly production of individual prototypes to the scalable production of dense metal parts. Depending on the requirements, different processes are used, including binder jetting with powder bed and the extrusion of metal-filled materials.

A wide range of materials are processed - e.g. stainless steels, copper, tool steels and nickel alloys. Systems with an open material platform are available for research and development, in which process parameters can be freely adapted and own powders and binders can be used.

Get in touch with us

Desktop Metal Studio System 2

Powder-free metal 3D printing for development and prototypes

The Studio System 2 offers a particularly easy introduction to metal 3D printing - without loose powder, without lasers and without shielding gas. It works with metal-filled filament, which is extruded in the first step and sintered in the second step. A separate debinding process is no longer required - debinding takes place automatically during the sintering process. This makes the system ideal for development departments, laboratories and technical offices.

- No powder, no inert gas environment required

- Just two steps: Printing and sintering

- Simple, clean handling - even in a workshop environment

- Supports materials such as 17-4 PH, 316L, copper, etc.

Desktop Metal InnoventX

Open binder jetting system for research, development and material testing

The InnoventX is a compact binder jetting system for metal-based 3D printing in laboratory and development contexts. With an open platform, flexible parameterization and broad material support, the system is ideal for universities, research institutes and industrial development departments. Thanks to its compact format, optional powder station and sintering furnace, a complete process can be realized in a small space.

- Binder jetting with high resolution and attention to detail

- Open parameters for research and material development

- Over 30 supported materials, including ceramics

- Compact, expandable and industry-oriented

Desktop Metal Shop System

Binder jetting for the industrial production of metal parts

The Shop System was developed for the scalable production of dense metal components using the binder jetting process. With its high printing speed, fine resolution and series-capable throughput, it is particularly suitable for use in production-related environments, e.g. for the production of small batches or functional end products.

- High productivity - up to 70 kg of parts per day

- Resolution up to 1600 × 1600 DPI for fine geometries

- Supports various stainless steel and nickel alloys

- Complete production system with powder handling and sintering

What makes Binder Jetting metal 3D printers stand out?

Printing without support structures

Binder jetting enables the production of complex metal components without any support structures. The surrounding powder stabilizes the component during the printing process, creating geometric freedom and significantly reducing post-processing.

High throughput at industrial resolution

Thanks to parallel layer processing - without moving lasers or nozzles - large quantities can be printed in a short time. Resolutions of up to 1600 DPI enable fine detail reproduction and high dimensional accuracy at the same time.

Material diversity and cost-efficient operation

Binder jetting systems support a wide range of metallic materials - including stainless steels, copper and nickel alloys. The use of standardized MIM powders and the recycling of unbound material ensure economical operation.

Blog post: Comparison of different metal 3D printing technologies

Challenges when using metal 3D printers

Whether binder jetting, filament-based process or laser powder bed: metal 3D printing opens up new possibilities - but also entails certain process-related requirements. If you want to produce functional, dense metal parts, you should consider the following points

Post-processing is part of it

Almost all metal 3D printing processes first produce a so-called green part or blank. The component only achieves its full strength and density through subsequent steps such as drying, debinding and sintering.

Warpage during sintering

The loss of size during sintering can lead to distortion - especially with intricate geometries. Specialized software such as Live Sinter from Desktop Metal helps to specifically compensate for such effects.

Handling metal powder

Powder bed-based processes such as binder jetting or LPBF work with loose metal powder. This has advantages in terms of material efficiency, but requires careful handling, cleaning and certain protective measures.

Higher entry costs

Compared to plastic printing or filament-based desktop systems, getting started with metal 3D printing is more challenging. On the other hand, it opens up new manufacturing possibilities - such as the production of complex small series without tools.

Binder jetting in practice: Azoth 3D

See how Azoth 3D uses the Desktop Metal Shop System to produce complex metal components in series - quickly, flexibly and without tooling costs.

Further insights:

In our blog post, you can find out more about how binder jetting is changing industrial production and what benefits companies like Azoth are deriving from it:

Practical insights: How Binder Jet metal 3D printing is changing industrial production

What is involved in post-processing in metal 3D printing?

De-powdering and drying

After printing, the unbound powder is removed from the component and stabilized in a drying step - particularly important for binder jetting.

Debinding

The binder contained in the green part is thermally removed. This step is crucial for the subsequent density and structure of the component.

Sintering

The metal is compacted by heating it to just below its melting point. This causes the component to shrink - by up to 20 % depending on the material.

Optional steps

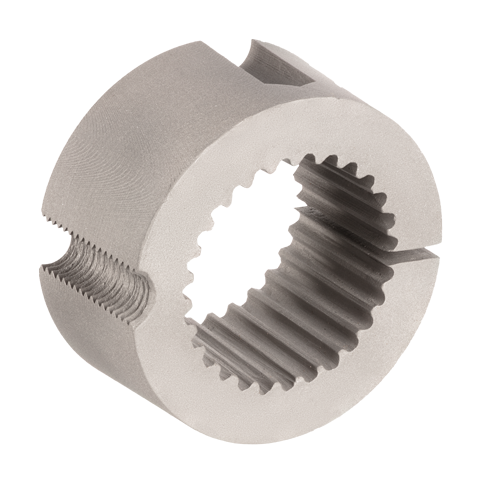

Depending on the application, further work steps such as CNC post-processing, surface finishing, heat treatment or thread cutting follow - as with conventionally manufactured metal parts.

Read our blog post for more detailed information:

Process accessories - for a stable metal 3D printing workflow

Reliable results in metal 3D printing require more than just a good printing system. Depending on the technology, additional process steps such as depowdering, drying and sintering are also required. Desktop Metal offers coordinated devices that can be seamlessly integrated into the overall process - from the research laboratory to series production.

Available as an accessory:

- Powder station - Closed working chamber for safe powder removal and powder recovery

- Drying oven - Removes solvent residues from the green part before sintering

- Sintering furnace (PureSinter) - Compact laboratory furnace, optimized for the InnoventX system

- Store System sintering furnace - Industrial furnace with high throughput, tailored to series production

The right combination of printer and process accessories forms the basis for a stable, reproducible workflow - from development to small series.

Contact and for more information

The CHROMOS way to the optimum solution

Understanding requirements

We analyze your requirements precisely - from the desired component size to material properties and throughput. We also include the production environment in the planning.

Propose technology and solution

Based on the analysis, we select the right 3D printing technology and the optimal device. We plan the entire process together - including material selection and post-processing.

Test feasibility

Our technicians will set up your 3D printer and ensure optimal configuration. We offer training for your team on request.

Integration and support

We are also there for you after the purchase - with reliable support, material replenishment and technical assistance.

Our tip: Get advice from our experts

Not every 3D printer is suitable for every application - and not every printing technology is ideal for all materials, component sizes or production requirements.

We help you to find the perfect solution for your projects - precise, efficient and optimally tailored to your requirements.

Contact us

Our experts will be happy to help you. Get in touch with us!