Label lids and closures

Secure coding on plastic and metal fasteners - high-contrast, durable and suitable for lines

Caps and closures are usually marked in confined spaces and at high line speeds. Quick-drying, abrasion-resistant marking is particularly important on plastic caps, snap-on lids or screw caps. This requires precise print images that adhere reliably and remain permanently legible, even on curved or structured surfaces. At the same time, printing systems must be able to be integrated into existing production lines continuously and without disruption - even with varying shapes, materials and format orientations.

Get in touch with usWhy is the labeling of lids and closures important?

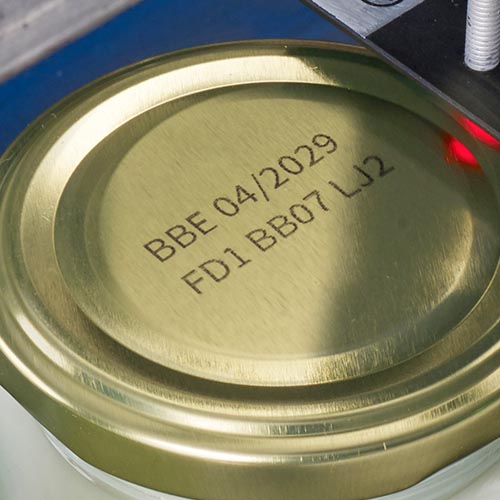

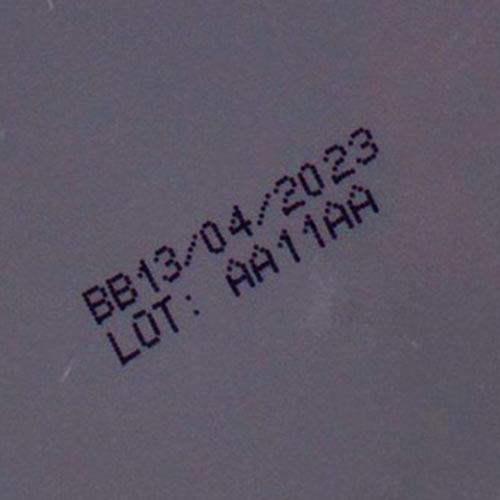

Ensure traceability

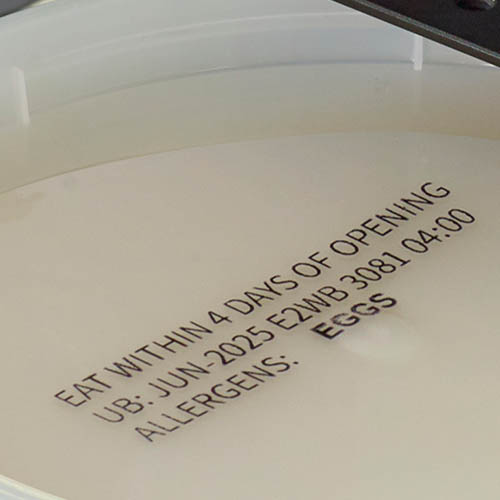

Production data such as batch, filling time or best-before date are often placed on the lid - clearly visible and directly linked to the product.

Legibility at the point of sale

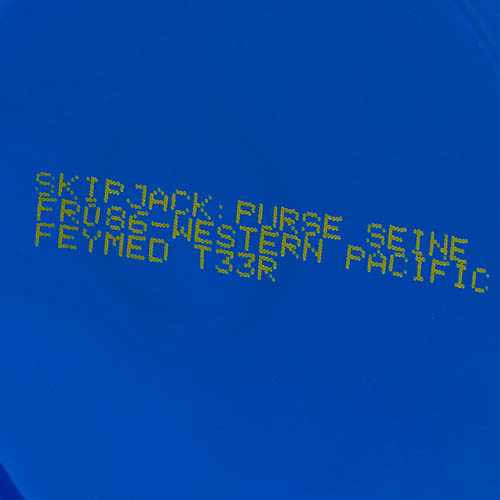

Especially for beverages and packaged foods, the lid marking is often the only clearly visible coding for retailers and consumers.

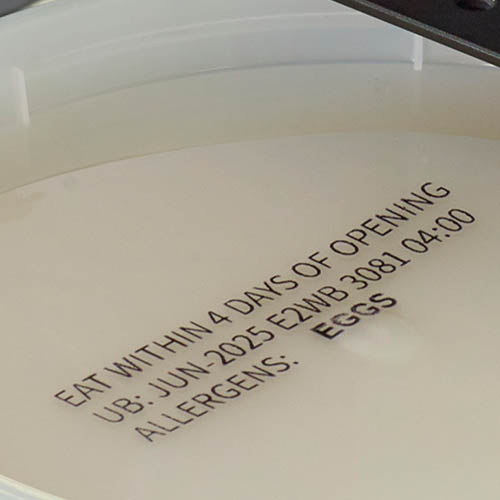

Meet legal requirements

In many industries - such as food, beverages and pharmaceuticals - tamper-proof and permanent labeling is mandatory.

Challenges in the labeling of plastic bottles

Depending on the type of lid and production environment, there are special requirements for the print image, drying and legibility. These three points are among the most common challenges:

Limited space on the surface

Lids often only offer a few square centimetres of space for printed content. The labeling must therefore be particularly compact, but still clearly legible.

Irregular or curved shapes

Many closures are textured, ribbed or domed. The printing technology must be able to handle varying surfaces reliably.

Short cycle times and fast lines

In high-speed lines, only a fraction of a second remains for marking. Ink must dry quickly and the print must be positioned reliably.

Suitable technologies

Three main printing technologies can be used for marking lids and closures - e.g. made of PE, PP or metal. The most suitable solution depends on the material, line speed and surface structure. Decisive factors are the adhesion of the marking, its legibility on small surfaces and its suitability for curved or irregular shapes.

Get in touch with us

Continuous Inkjet (CIJ)

CIJ printers are the first choice for closures with a high cycle rate. They process fast-drying inks, adhere securely to plastic and enable clean codes even on round or structured surfaces.

- High line speed with variable product position

- Good adhesion inks for PE, PP and painted metal closures

- Suitable for production data, MHD and batch codes

Laser marking

Lasers mark permanently and without consumables. If the lid material is suitable - e.g. with black or specially additivated surfaces - a high-contrast, abrasion-resistant code is created directly in the material.

- no ink, no drying time

- Forgery-proof and permanent engravings

- depending on color, additives and surface structure

Thermal Inkjet (TIJ)

TIJ systems are primarily used for flat or precisely guided lids. They enable high-resolution print images with low maintenance requirements.

- Ideal for synchronized lines with a defined product position

- High print resolution for texts, logos or 2D codes

- Quick changeover for format changes

The CHROMOS way to the optimum solution

Requirements analysis

We check what requirements your line has in terms of drying, adhesion, print image and speed - and which materials are in use.

Technology selection based on real conditions

Whether plastic lids, metal closures or special shapes: we select the right printing technology based on specific requirements and material properties.

Test marking on original parts

In our application laboratory, we test the coding directly on your products - under realistic conditions and with different systems.

Integration, support and further development

Our specialists provide support with integration into your line, train your team and are also on hand to help with changes or new product formats.

Our tip: Get advice from our experts

Small surface area, high speed, demanding material - the best way to determine the right technology is to test it. We provide you with practical and application-specific advice.

Get in touch with usApplication examples

Contact us

Our experts will be happy to help you. Get in touch with us!