Labeling film packaging

Variable coding on flexible packaging - reliable, high-contrast and process-safe

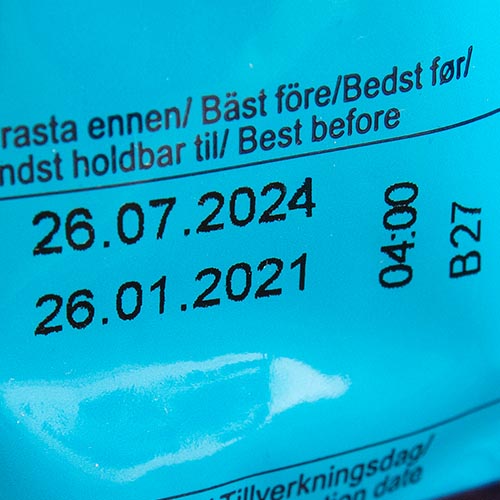

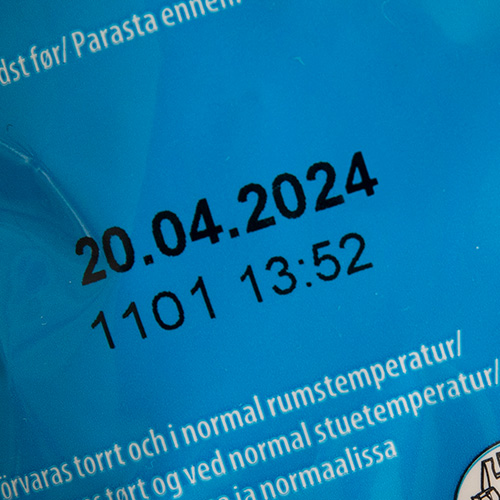

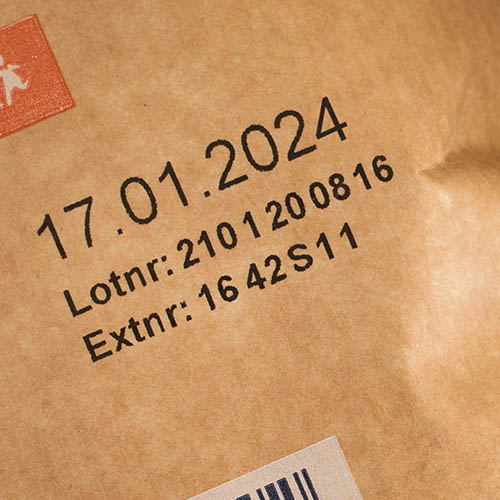

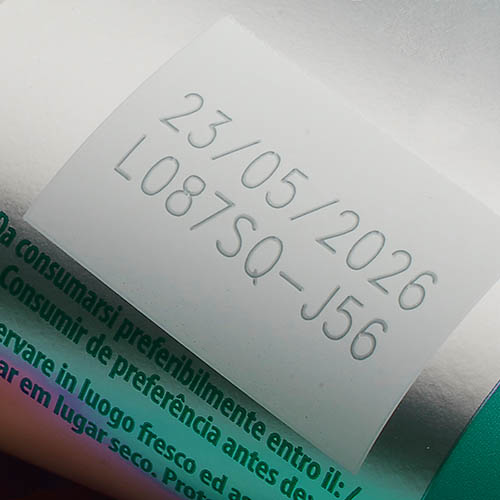

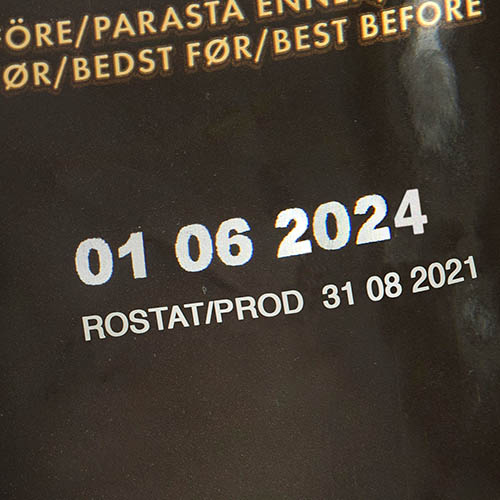

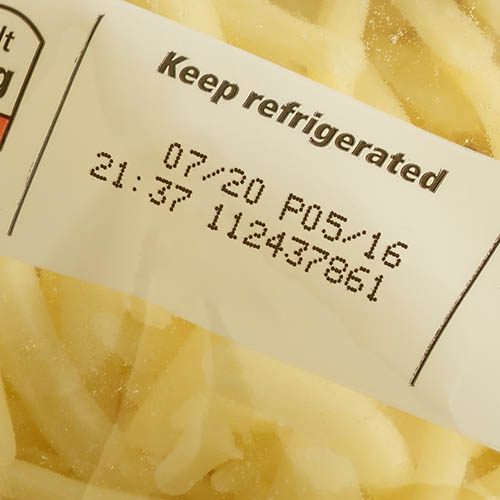

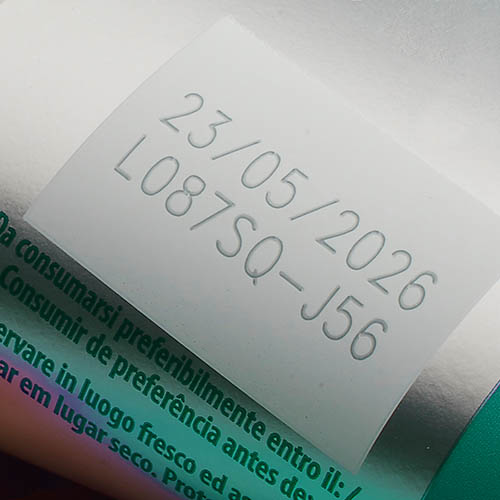

Flexible packaging made of film is now standard in the food, pharmaceutical and consumer goods industries. Whether flowpacks, pouches, stickpacks or sachets - best-before dates, batch numbers, barcodes or UDI codes must be applied to them precisely and legibly.

For reliable marking on films, it is not only the print quality that counts, but also the adhesion to smooth surfaces, the drying time, the contrast and the resistance to abrasion, heat or packaging processes. In this article, we show which technologies can be used for reliable industrial marking on films.

Get in touch with usWhy is the labeling of film packaging important?

Ensure traceability: Batch or time codes on film packaging enable seamless traceability - even with high cycle times or automated packaging lines. This ensures compliance with legal requirements and quality assurance.

Product safety & information: Best-before dates, production times or other variable information must also be clearly legible and durable on glossy, flexible or thermoformed surfaces - even when exposed to moisture, heat or static electricity.

Protect brand integrity: Clear, tamper-proof codes strengthen trust in the brand - especially for promotional packaging, export products or applications with a high risk of tampering.

Challenges in the labeling of film packaging

Film packaging places special demands on coding. The combination of material properties, processing steps and production speed calls for sophisticated solutions:

Difficult surfaces

Many films are smooth, glossy or specially coated - this makes it difficult for inks to adhere or laser markings to be read.

Deformation in the process

The surface can deform during sealing, cutting or thermoforming - coding must remain legible even after the packaging step.

High speed

Packaging lines work at high cycle rates. The marking must remain precise and reliable - even with changing formats.

Static

charging

Plastic films tend to become electrostatically charged. This can affect the ink distribution or impair the coding quality.

Suitable technologies

Various technologies are used for marking film packaging, depending on the application - including thermal transfer printing (TTO), laser and continuous inkjet (CIJ).

The most suitable solution depends on the type of film, the packaging process and the requirements for legibility, durability and production speed, among other things.

Thermal transfer printing (TTO)

TTO printers apply high-resolution codes directly to flexible packaging films - without contact and with high precision. Particularly suitable for:

- Intermittent or continuous packaging processes (FFS machines)

- razor-sharp texts, barcodes or graphics

- Variable data at high cycle rates

Continuous Inkjet (CIJ)

CIJ printers with specially formulated inks enable flexible and reliable labeling of a wide range of film types. Particularly suitable for:

- Flexible adaptation to different packaging materials

- Quick-drying inks, even on surfaces treated with lubricants

- Labeling in high-speed lines

Thermal Inkjet (TIJ)

TIJ systems offer a compact solution for simple coding tasks on films - ideal where space is limited and printing requirements are clear. Particularly suitable for:

- Small barcodes, data matrix codes or plain text

- Packaging lines with low to medium throughput

- Solvent-free applications

Laser

Lasers mark film packaging without contact - either by removing material (e.g. with coated or lacquered films) or by a light-based reaction on the surface (e.g. with monofilms). Particularly suitable for:

- Permanent, abrasion-resistant markings without ink

- High line speeds

- Applications with recyclable materials or high hygiene requirements

The CHROMOS way to the optimum solution

Understanding requirements

You describe your application to us - we clarify materials such as monofilms, multilayer films or coated substrates as well as the production environment, packaging process (e.g. FFS) and requirements for legibility, durability and positioning of the codes.

Suggest technology and solution

Based on your situation, we will show you suitable technologies and implementation options - for example thermal transfer printing, CIJ or laser solutions - for reliable and process-safe marking on film packaging.

Testing feasibility

In realistic tests, we check the legibility, durability and material compatibility of the marking - tailored to your packaging line and the specific requirements of your film materials.

Integration and support

We support you with selection, integration and commissioning - with experienced technical support and comprehensive expertise in flexible packaging labeling.

Our tip: Get advice from our experts

Not every film packaging is the same - and not every marking technology is suitable for every material, packaging process or product design.

We help you to find the right process for your production line and your packaging - high-contrast, process-reliable and permanently legible.

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!