Optical packaging inspection and seal control

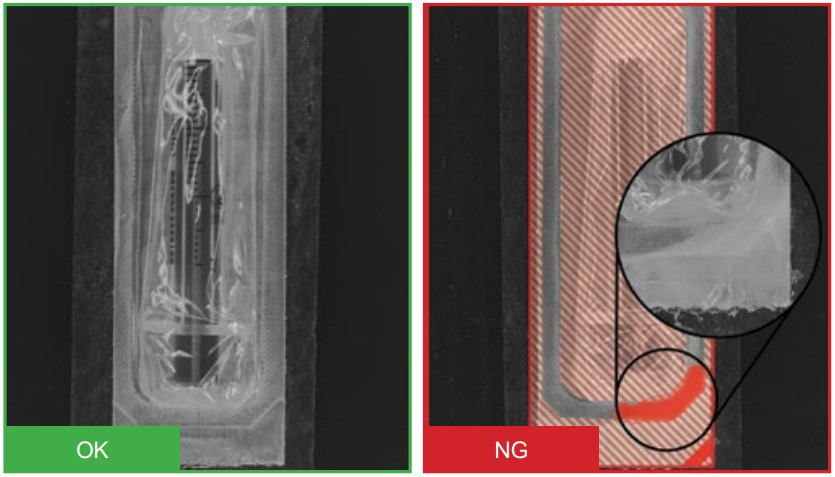

Machine vision systems check packaging and seal seams for defects, damage and incomplete closures - inline and reliably.

In industrial production, not only the products themselves, but also their packaging must meet the highest quality standards. Optical systems detect whether sealing seams are closed correctly, whether packaging is free of creases or inclusions and whether labels have been applied correctly. Defective packaging can therefore be sorted out at an early stage before it leads to complaints, safety risks or production downtime. Machine vision therefore makes a significant contribution to process reliability, product protection and brand quality.

Get in touch with usWhy is optical packaging inspection important?

Ensuring product safety: A faulty seal seam can have serious consequences in the food or pharmaceutical sector. Optical systems ensure that packaging is reliably sealed and product safety is guaranteed at all times.

Avoid complaints and rejects: Damaged packaging, incorrectly positioned labels or open areas lead to returns and costs. Thanks to the inline inspection, errors are detected immediately and affected products are automatically ejected.

Ensure brand quality: Packaging is often the first thing customers see. Clean, flawless packaging strengthens trust and underlines the quality perception of a brand. Machine Vision ensures that every item meets this requirement.

Challenges when using vision systems

The optical inspection of packaging and sealing seams involves special requirements. Different materials, high cycle rates and varying defect patterns require robust and precise solutions. In order for vision systems to work reliably, they must be adapted to the real production conditions.

Different materials and films

Packaging often consists of transparent, metallized or multi-layer films that are highly reflective. These properties make it difficult to detect defects and make coordinated lighting and image capture essential.

High line speeds

Hundreds of units are processed every minute in packaging lines. Vision systems must detect and evaluate the smallest deviations within milliseconds and, if necessary, trigger a rejection - without interrupting the production flow.

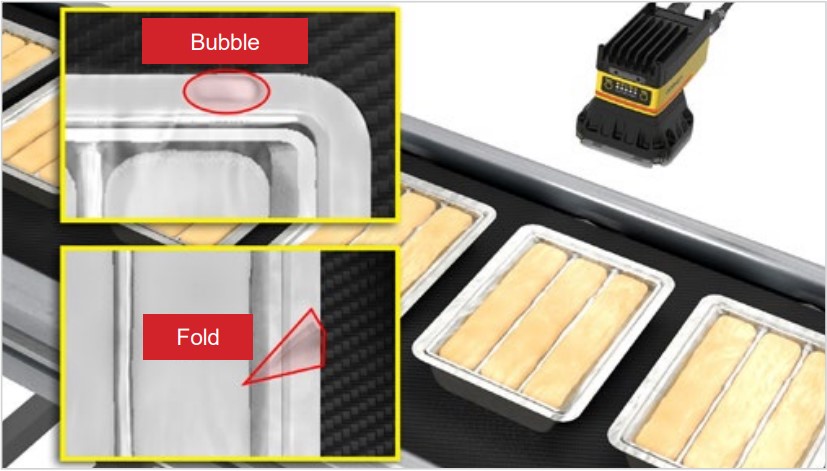

Varying error patterns

Wrinkles, inclusions, foreign bodies or incomplete seals occur in very different forms. Systems must be so robust that they can also reliably detect and classify irregular and rare defects.

Suitable machine vision technologies

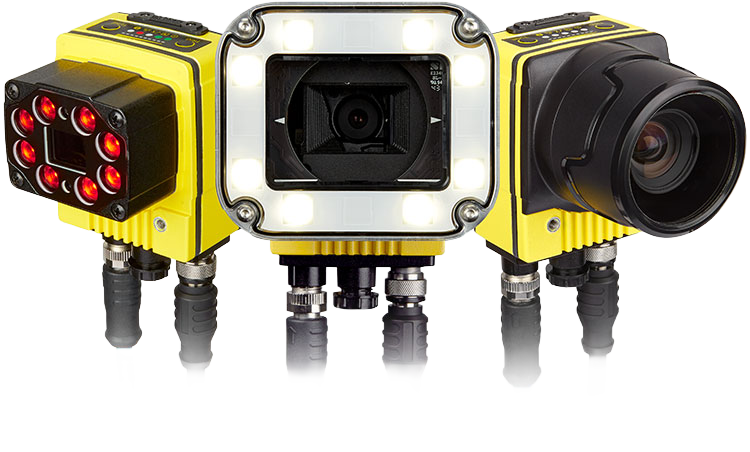

The inspection of packaging and sealing seams requires systems that can reliably distinguish between faultless and faulty products - even with difficult materials and at high speeds. Different approaches are used depending on the requirements: from flexible industrial cameras and compact smart cameras to AI-supported processes.

Get in touch with us

Industrial cameras with external evaluation

The combination of industrial camera and powerful software offers maximum flexibility for packaging and seal inspection.

- Freely selectable optics and lighting for different materials

- Precise analysis even with complex error patterns

- Expandable for multi-camera solutions and large line widths

Smart cameras

Compact systems with integrated evaluation, which are particularly suitable for standardized tasks.

- Simple integration into existing lines

- Stable with clearly defined error characteristics

- Low space requirement and fast commissioning

AI-supported processes

Deep learning algorithms recognize errors that are difficult to detect using conventional rules. This means that even varying or irregular deviations can be reliably identified.

- Robust against changing defect patterns such as creases or open areas

- Able to learn on the basis of practical image data

- Supplements existing systems and increases reliability

The CHROMOS way to the optimum solution

Analysis and consulting

We evaluate products, packaging materials and line speeds and determine which vision technologies are best suited for reliable packaging and seal inspection.

Test setup and validation

In realistic tests, we combine cameras, optics and lighting to ensure the detection of typical error patterns. This allows us to prove the practicality of the solution at an early stage.

Integration into the production line

Our systems can be seamlessly integrated into existing systems - including interfaces to PLCs, databases and reject mechanisms. Results are available in real time and ensure stable process control.

Support and further development

We support operations with local service, training and adaptations to new types of packaging or product variants. This keeps quality assurance up to date in the long term.

Contact us

Our experts will be happy to help you. Get in touch with us!