Product packaging is extremely important. No matter how good and beautiful the product inside may be, if the packaging has flaws, this is a flaw that puts customers off. After all, the outside always reflects on the inside. Many potential customers also judge the price of a product by the appearance of the packaging. If the packaging is broken or damaged, a customer is not prepared to pay the original price.

Companies must therefore do everything they can to offer consistent quality throughout. Customers want the same quality every time they buy a product. They are also prepared to pay more for this.

Many industries around the world rely on the high quality of Swiss products. The quality of luxury products in particular is world-renowned, but machines for production are also popular.

Quality control is a step in the production process that is extremely important in order to guarantee a consistent external appearance and quality.

Machine vision vs. deep learning

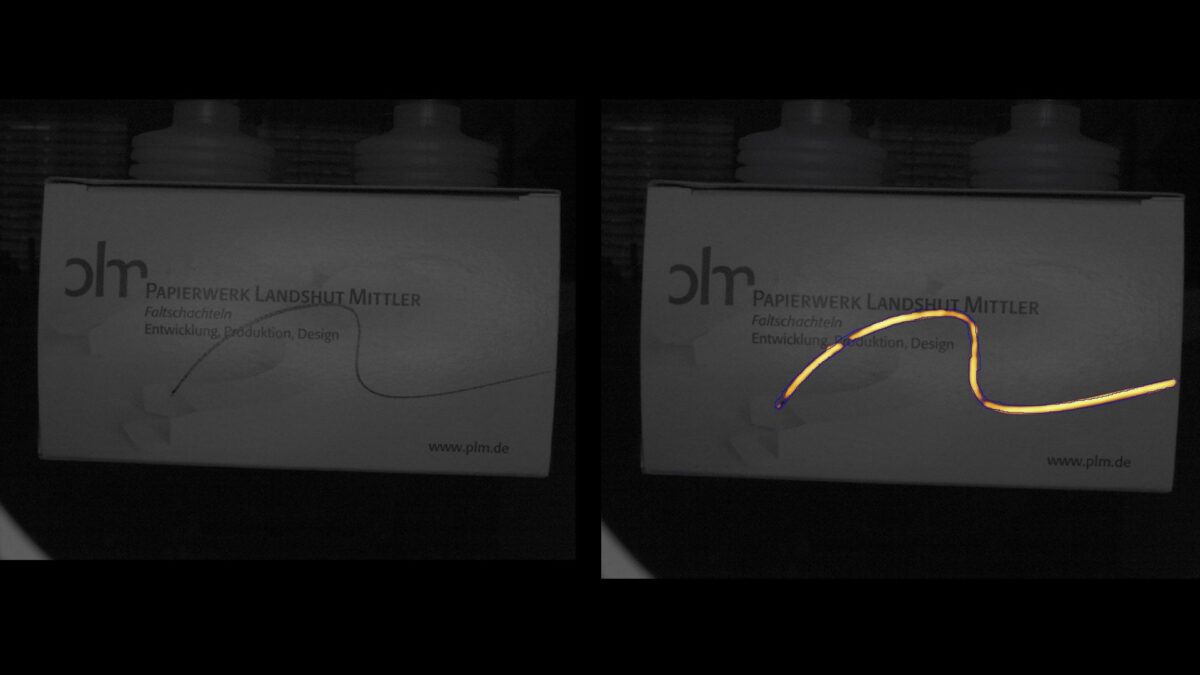

Conventional machine vision does this quite well, but often fails when it comes to scratches, cracks, oil stains, fingerprints and wrinkles. That's why you need more than machine vision. You need artificial intelligence that reliably detects these defects.

Retina Deep Learning software is one of the possibilities. This software reliably detects such errors and is easy to use.

The deep learning software processes the images directly on the production line completely independently and can make decisions within fractions of a second. A fast internet connection is therefore not necessary.

Another advantage of the Retina Deep Learning software is that it is quickly ready for use. Only a relatively small number of images are required for training and testing. Playing through the epochs also only takes minutes and not hours or days, as with other solutions.