In 2025, label and packaging printing will be at a point where existing developments are noticeably intensifying and having an impact on new fields of application. Many of the defining trends - sustainability, digitalization, automation, greater product safety, intelligent functions and user-friendly formats - are not entirely new phenomena, but have been part of the industry debate for years. What is new is that they are now being implemented more broadly, more consistently and often in combination, opening up new areas of business. We have summarized the most important trends.

Sustainability as a long-term driver

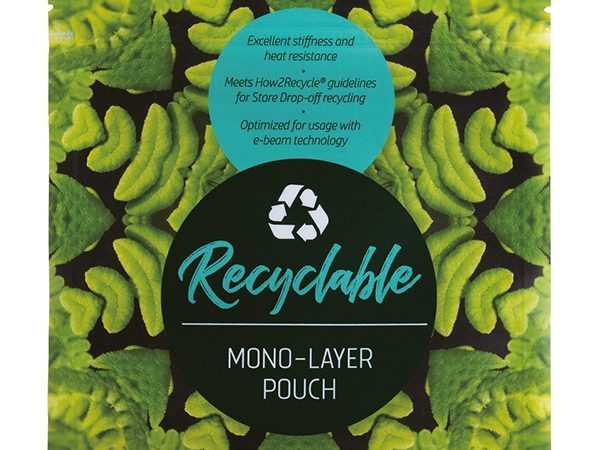

The topic of sustainability has been a key benchmark for the packaging industry for many years - and in 2025 this demand will visibly increase across the board. Stricter regulatory requirements - in particular the European Packaging and Packaging Waste Regulation PPWR, which came into force in February 2025 - increasing environmental awareness and growing consumer expectations mean that recyclable, resource-saving and CO₂-reduced solutions are no longer seen as an additional benefit, but as the standard. In flexible packaging, mono-material concepts that are easier to process in existing recycling systems and reduce transportation costs thanks to their low weight are gaining in importance. Developments aimed at improving recyclability can also be seen in label printing - for example through thinner films, optimized carrier materials or the use of alternative substrates. These material innovations are increasingly being combined with processes that reduce waste, for example through more precise print preparation and automated quality assurance. The direction has been set for years - the difference today is that sustainability not only shapes individual product lines, but is integrated into the entire production strategy.

Convenience and suitability for everyday use

Convenient, easy-to-handle packaging has long been an established success factor - in 2025, this trend will prevail in even more product categories. Stand-up pouches, resealable sachets, squeeze packs and easy-open pouring solutions are now standard in numerous markets, from snacks and baby food to care products and nutritional supplements. Flexible packaging scores points here with its low weight, space-saving storage and the ability to combine protective and convenience functions. In label printing, a clear, easy-to-read design supports user-friendliness: variable data such as shelf life or batch information, clear product labels and multilingual content can be quickly adapted using digital technology. The focus on suitability for everyday use is also supported by changing lifestyles - more single households, mobile working patterns and the desire for immediate availability have led to packaging solutions being increasingly adapted to the context of use.

Digitalization and personalization

Digitization has already had a significant impact on label printing - with shorter set-up times, flexible choice of motif, variable data printing and cost-effective production of even the shortest runs. These principles are also increasingly being applied to flexible packaging. While the proportion of digital printing was low for a long time, it is now accelerating significantly. The ability to adapt packaging regionally or seasonally, individualize series or quickly implement limited editions opens up new scope for marketing and product differentiation. Hybrid technologies that combine digital flexibility with the efficiency of conventional processes help to optimize production costs while expanding the portfolio of variants. This development is not entirely new - but it shows that tried-and-tested digital concepts from label printing are increasingly establishing themselves as the standard in adjacent packaging segments.

Intelligent packaging and e-commerce

The integration of digital elements into packaging began years ago in the label sector - QR codes, NFC chips and variable serial numbers are well-known tools for providing authenticity, traceability and additional information. In 2025, it will become clear that these functions are now also being systematically integrated into flexible packaging. This is not just about marketing, but also about efficiency and security in the supply chain. The ongoing e-commerce boom is reinforcing this trend: packaging must be able to withstand shipping loads while also being lightweight, space-saving and visually appealing. Smart markings offer the opportunity to track products throughout transportation, simplify returns processes and provide consumers with additional content directly on the packaging. This development is also evolutionary, not revolutionary - but its increasing widespread implementation makes it a defining factor in the current market landscape.

Product safety and barrier technologies

The requirements for product protection and shelf life have increased continuously in sensitive markets such as food, pharmaceuticals and cosmetics. Advances in high-barrier films, special coatings and low-migration adhesives now enable longer shelf life, better protection against moisture, oxygen or light and greater protection against contamination. Flexible packaging benefits here in particular, but these technologies are also used in the label sector, for example for sleeves or security labels. What is new is not the objective, but the breadth of implementation: what was only conceivable for certain premium products a few years ago is now increasingly becoming a standard requirement in series production.

Automation and supply chain resilience

Automated processes in prepress, printing and finishing have long been key to reducing costs, ensuring quality and responding to the shortage of skilled workers. In 2025, it is clear that these automation solutions will now be used much more widely. Digital workflows that process data end-to-end from order entry to final inspection will reduce error rates and speed up production. AI-supported inspection systems, automatic color control and robot-supported material logistics enable greater production reliability and flexibility. At the same time, these systems support the resilience of supply chains: production capacities can be shifted more quickly between locations and just-in-time concepts can be implemented even when demand fluctuates. For companies that have primarily manufactured labels up to now, this means the opportunity to align existing systems and workflows with an expanded product portfolio without having to reinvent fundamental processes.

Combined solutions make the difference

The combined use of several trends results in particularly efficient solutions: For example, digital printing on flexible, environmentally friendly mono-materials enables the production of individual, sustainable pouches in small quantities. Downstream pouch production on compact, automated pouch machines and intelligent packaging technologies (e.g. QR-ginger, variable data, barrier functions) creates modular production chains that can be flexibly scaled. This combination is particularly attractive for products with high customization potential - such as regional editions, limited drops or personalized series in cosmetic or specialized food segments.

Conclusion and recommendation for Labelexpo visitors

The key developments - sustainability, convenience, digitalization, intelligent functions, product safety and automation - are not new, but their implementation is becoming more comprehensive, faster and more self-evident.

For visitors to Labelexpo, this means focusing specifically on solutions that bring these established trends to the masses: production systems that enable a seamless transition between label and flexible packaging, materials and designs that facilitate recycling and resource conservation, technologies for variable data and personalized series in short runs as well as automated workflows that increase both efficiency and flexibility. Those who identify the right investment areas here can not only serve existing markets, but also open up new business areas and position themselves as a flexible partner for a wide range of customer requirements in the long term.