Binder Jet metal 3D printing is increasingly establishing itself as a key technology in industrial production. The Desktop Metal Shop System, the world's best-selling system of its kind, enables companies to produce metal parts in medium quantities in a cost-efficient and flexible manner. It offers a fast and economical alternative to traditional manufacturing processes such as milling, precision casting or metal injection molding (MIM). Small and medium-sized companies in particular benefit from the opportunity to speed up their production processes, optimize supply chains and guarantee the highest quality standards. Three practical examples are presented below that impressively demonstrate how Desktop Metal Shop System is used in industrial production.

Efficient supply chains and on-demand production at Azoth 3D

Traditional production processes such as machining, investment casting or metal injection molding (MIM) are often associated with long lead times that can cause weeks of production delays. Azoth 3D specializes in manufacturing precision parts using production-ready additive technologies. The company uses the Desktop Metal Shop System for metal binder jet 3D printing to create prototypes, run pilot series and go straight into production without additional tooling. This allows Azoth to reduce lead times for stainless steel parts from up to four weeks to just 10 to 15 days. At the same time, printing multiple iterations enables faster testing and design optimization.

Azoth integrates binder jetting into a comprehensive supply chain management solution that enables customers to convert physical inventory to digital and produce parts on demand with no minimum order quantity. The "Take One Make One" (TOMO) strategy eliminates supply chain disruptions through qualified on-demand production of metal components.

The screw placement grippers shown below are integrated into a robotic arm to grip and place thousands of screws on an assembly line every day. Although these parts appear simple to machine at first glance, the complex teeth in the design would require precision machining and multiple tool changes.

"These grippers are the perfect TOMO example. They are more cost-effective to manufacture with binder jetting and can be provided with a delivery time of just 10 days instead of eight weeks."

Cody Cochran

Co-founder and managing director of Azoth

By using the Shop System for medium-sized production, Azoth is able to produce 1,400 of these end products per day from 17-4PH stainless steel, heat-treated to H900, replacing traditionally machined tool steel components.

Download complete Azoth case studyPrecision through sinter correction: ABCorp's success story

ABCorp is one of the oldest manufacturing service providers in the US with a history of over two hundred years. At its 21,000 square foot facility in Boston, the company offers vertically integrated production for a variety of products. After initial experience with polymer 3D printing, the company turned to Desktop Metal Shop System to produce metal end-use parts in a functional production environment for the first time.

In addition to the user-friendly store system, a decisive factor for the immediate success of ABCorp's binder jetting processes is the Live Sinter software from Desktop Metal. This manufacturing preparation software provides advanced simulation tools to predict and correct errors in the sintering of 3D printed parts.

"One of my biggest concerns when investing in this technology was the sintering furnace and the potential frustration of failing so late in the process. With Live Sinter, I am thrilled with our success in the sintering furnace."

Neil Glazebrook

Vice President 3D Solutions at ABCorp

Instead of printing a part straight and running the risk of warped specifications, Live Sinter™ creates a negative compensation geometry that achieves the desired dimensional tolerances during sintering. This unique distortion compensation helps ABCorp increase success rates and reduce costs. "I no longer need to use sintering contactors and can therefore save on the cost of them. I use Live Sinter for everything and it makes us more competitive," says Glazebrook.

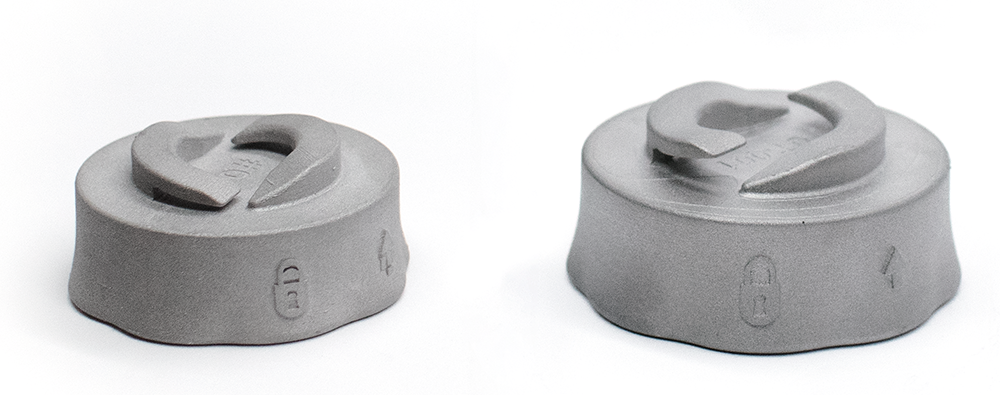

In conventional binder jetting production, the overhangs of the connectors in this denture weight shown below would require support structures in the furnace. By simulating warpage and distortion during sintering with Live Sinter, ABCorp can print a negative offset geometry that sinter straight.

Optimization of production capacities: Jade Groupe relies on Binder Jet 3D printing

Jade Groupe produces luxury fashion accessories exclusively for the prestigious LVMH Moët Hennessy Louis Vuitton group. The company covers the entire production cycle in its metal workshops, from injection molding and polishing to electrochemical coating and quality control. Jigs and fixtures are essential for production, but require expensive tools and long lead times, which can delay the market launch of end products.

"The high demand for tools, fixtures and other mechanical equipment overloads our specialized workshop, resulting in very long lead times and affecting production efficiency. Desktop Metal's systems speed up our production process by taking on some of the CNC workload."

Pedro Domingues

Additive Manufacturing Application Engineer at Jade Groupe

As the market for luxury goods grows, bespoke hardware is crucial to create a unique brand identity and signal quality. By adopting additive manufacturing, Jade Groupe can produce value-added hardware from customized tooling without the investment and long lead times of traditional production.

The wrench adapter pictured below was needed to standardize the process of closing an oven door on a production line. This seemingly small step was crucial, as an entire sintering run could fail if the pressure applied to the seal was inaccurate. Digital production with the Desktop Metal Shop System allowed the team to quickly create a part to solve this specific production problem without disrupting CNC production or ordering a standard part. Optimizing the design of this adapter for binder jetting reduced the weight by nearly half, and in-house production allowed for better process control.

Find out more about the Desktop Metal store system:

Contact us

Our experts will be happy to help you. Get in touch with us!