Labeling products

Requirements, technologies and solutions for different packaging materials

Product labeling is a central component of industrial processes. It fulfills regulatory requirements, enables traceability and supports internal processes in production and logistics. The technical requirements vary greatly: material properties, line speeds and environmental conditions influence the choice of suitable technology.

This page provides an overview of typical challenges, available processes and tried-and-tested solutions for marking different types of packaging - from plastic to corrugated board.

Why is product labeling important?

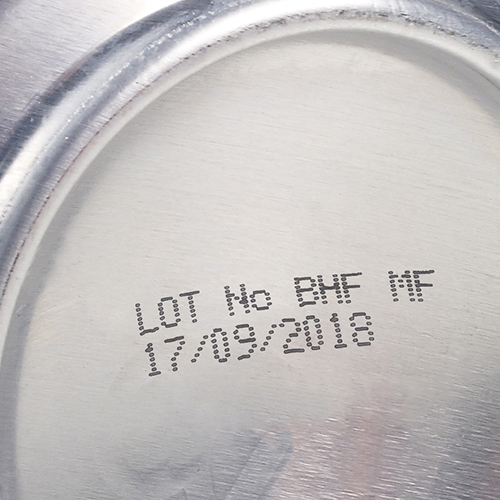

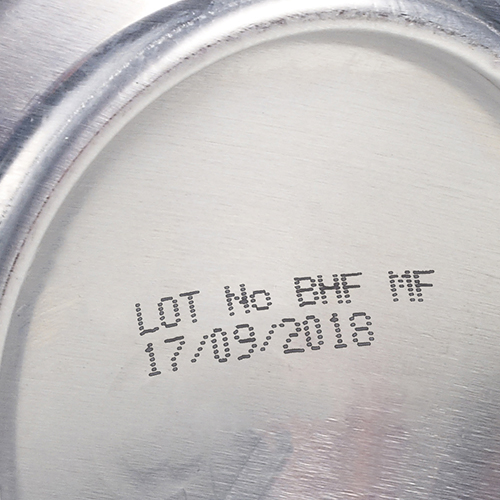

Ensure traceability:

Serial numbers, batch codes or time stamps enable seamless tracking - especially in the event of recalls or for proof of legal requirements.

Control production and logistics processes:

Clearly legible markings simplify the internal flow of materials, automatic identification in systems and warehouse and shipping logistics.

Provide information for end users:

Best-before dates, production times or other variable information are required for the proper use, sale or archiving of products.

Document quality assurance:

Standardized coding can be used to systematically track compliance with production parameters, test intervals or material batches.

Challenges in product labeling

The requirements for an industrial labeling solution depend on several factors - including the packaging material, the production environment and the technical conditions of the line. Typical challenges that need to be considered during selection and implementation are summarized below:

Material properties

Whether plastic, cardboard, metal or flexible film - every surface has its own physical properties. Absorbency, smoothness, coating or structuring influence the selection of the appropriate process.

Number of cycles and speed

High line speeds are standard in many industries. Marking must take place in real time without disrupting the production flow - with consistent precision and legibility.

Environmental influences

Condensation, cleaning processes, dust or temperature fluctuations can impair the adhesion and legibility of the marking. The technology must be designed to be correspondingly robust.

Shape and space conditions

Curved, structured or very small surfaces require precise alignment and flexible adjustment of the print position. Changing packaging formats must also be taken into account.

Data integration

Serial numbers, production times or batch codes are often taken directly from ERP or control systems. The marking solution must be able to handle variable data reliably.

Readability and durability

Depending on the requirements, high-contrast, abrasion-resistant or tamper-proof markings are necessary - especially for long storage times, export products or safety-relevant applications.

Suitable technologies

Industrial marking is carried out using different processes, each of which has specific strengths in terms of print image, speed, integration and material compatibility. Whether with ink, laser or label - each technology is based on its own physical principle and is particularly suitable for certain requirements.

Get in touch with us

Continuous Inkjet (CIJ)

In this process, a fine ink jet is continuously generated and directed onto the product.

- High line speed and cycle stability

- Suitable for uneven or damp surfaces

- Large selection of inks for different materials

Thermal Inkjet (TIJ)

TIJ printing systems work with heated nozzles that produce tiny ink droplets through vaporization.

- Very good print quality for text and 2D codes

- Compact, low-maintenance and easy to integrate

- Ideal for smooth, coated or sensitive surfaces

Drop-on-demand (DOD) / large character printer

Ink is only ejected from individual nozzle chambers as required - for large, high-contrast characters.

- Large character height and good legibility at a distance

- Robust against environmental conditions

- Flexible print fields for changing packaging sizes

Thermal transfer printing (TTO)

TTO systems transfer color pigments from a ribbon to the substrate using a heated print head.

- Clean print image with high durability

- Particularly suitable for flexible packaging

- Integration into intermittent or continuous processes possible

Laser marking

A bundled beam of light changes the surface of the material by ablation, engraving or color change.

- Permanent, smudge-proof marking without consumables

- Variants: CO₂, fiber or UV laser for different materials

- Precise, low-maintenance technology for high cycle rates

The CHROMOS way to the optimum solution

Understanding requirements

Together we clarify materials, line conditions, print content and requirements for legibility, adhesion and durability.

Propose technology and solution

Based on the circumstances, we show you suitable processes - including technical variants and integration options.

Testing feasibility

We test print quality, adhesion, material compatibility and process integration in realistic trials.

Integration and support

From selection to installation and commissioning - with technical expertise and support throughout the entire project.

Our tip: Get advice from our experts

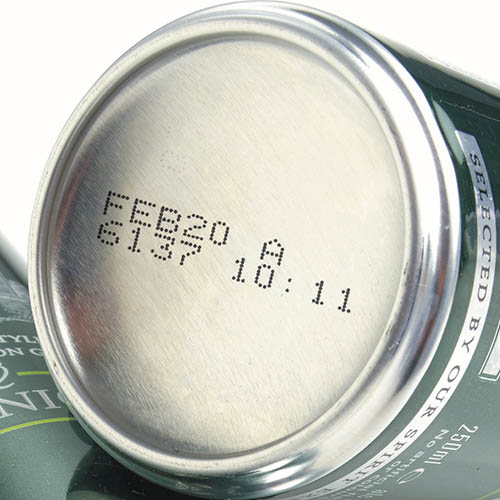

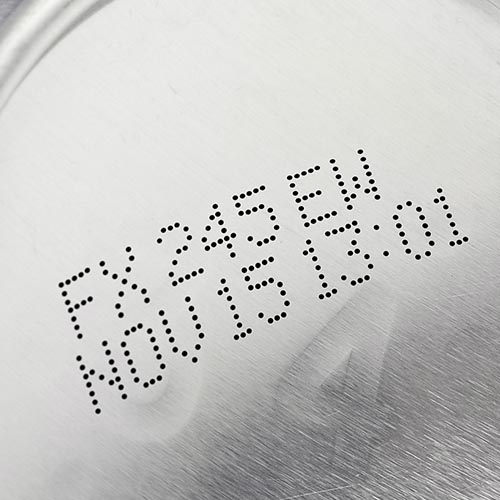

Not every can is the same - and not every marking technology is suitable for every material or product design.

We help you to find the right process for your line and your cans - high-contrast, reliable and permanently legible.

Case study: Can marking with fiber laser at Pepsi Bottling Ventures

Pepsi Bottling Ventures, the largest independent Pepsi bottler in North America, relies on fiber laser technology from Domino to code its beverage cans. The system delivers reliable, easy-to-read codes even in condensation - at up to 60,000 cans per hour.

"Production line efficiency has improved, production costs have decreased, as have customer complaints about poor print quality."

- Sabri Kundakcioglu, Vice President of Engineering, Pepsi Bottling Ventures

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!