Text and image: Sima Toltzis Morad, Global Commercial Printing Segment Manager at HP Indigo

The commercial printing industry is undergoing the fastest transformation in its history. Changing customer needs, skills shortages, rising costs, limited access to capital, a shrinking traditional print market and disrupted supply chains are forcing printers to make strategic decisions.

Three key questions are currently preoccupying many entrepreneurs:

- How can I increase the profitability of my business?

- How can sales be increased?

- And how can I effectively meet the challenges in the HR area?

As difficult as these challenges are, they also offer opportunities for new growth. HP Indigo believes that with the right innovations in digital printing, companies can turn these hurdles into competitive advantages through new revenue streams, more efficient processes and a strengthened market position.

Standing out in a stagnating market

Although the entire commercial printing market is expected to shrink by 2% annually until 2028, a closer look reveals that digital printing is clearly on the rise: Digital printing is clearly on the upswing. While the analogue sector is expected to decline by 3% between 2024 and 2028, digital commercial printing is forecast to grow by 5.4%.

(Sources: SMITHERS, HP, print market data)

This trend is being driven by a fundamental change in print jobs: High-quality applications in general commercial printing (GCP), photo products, advertising materials and on-demand publishing are becoming increasingly important. At the same time, the volume of transactional printing and traditional office jobs is continuously declining.

Digital printing helps to overcome key challenges arising from the changing structure of print jobs. It enables commercial print shops to offer exactly the products and services that modern print customers expect.

Decreasing print runs and shorter lead times

Regardless of the order, the print runs are getting smaller and smaller. The days of producing tens of thousands of catalogs at once are over. Typical print jobs comprise around 2,500 copies for catalogs and less than 4,000 copies for brochures. Almost 70 % of all direct mailings have a print run of less than 10,000 copies. The volume of small print runs is expected to increase by 12.5 % by 2028. This underlines the growing importance of digital commercial printing.

(Source: Smithers-Pira, Future of Print to 2030, June 2020, Keypoint Intelligence, survey of 165 print service providers in the USA, commissioned by WE and APJ, June 2021)

Web2Print and e-commerce platforms are setting new standards in terms of time to market - with average delivery times of just 1 to 3 days. This increases the pressure on the industry to move towards faster, more efficient and automated processes with seamless traceability.

AI-based image generation and personalized printing

AI design tools and the boom in e-commerce have democratized creative design. Today, over 34 million images are already generated by AI every day - enabling highly dynamic, changeable order creation. This development is particularly strengthening the micro-order segment. This goes hand in hand with the growing expectation of tailor-made communication: more than two thirds of US print shops already produced personalized print products in 2024.

(Source: NAPCO Annual Commercial Print Industry Trends and Strategies Survey

Digital printing as a sales driver

Although digital printing currently only accounts for around 5% of the commercial printing volume, it already accounts for around 25% of the industry's turnover - a clear indication of its economic relevance. HP Indigo recommends a hybrid production model consisting of analog and digital machines. A strategic ratio of 80% standard jobs to 20% high-margin specialty jobs has proven to be ideal for ensuring sustainable profitability.

Offset quality and digital flexibility

HP Indigo Liquid-Electro-Photography (LEP) technology is at the heart of the transformation. It combines offset quality with the advantages of digital production - such as flexibility, job changes and media compatibility. This means that both coated and uncoated substrates can be used - with no visible differences for customers. A practical example: the Heenemann print shop in Germany shifted two million B2 sheets to HP Indigo machines within a year and achieved company growth of 20% as a result.

Focus on productivity and versatility

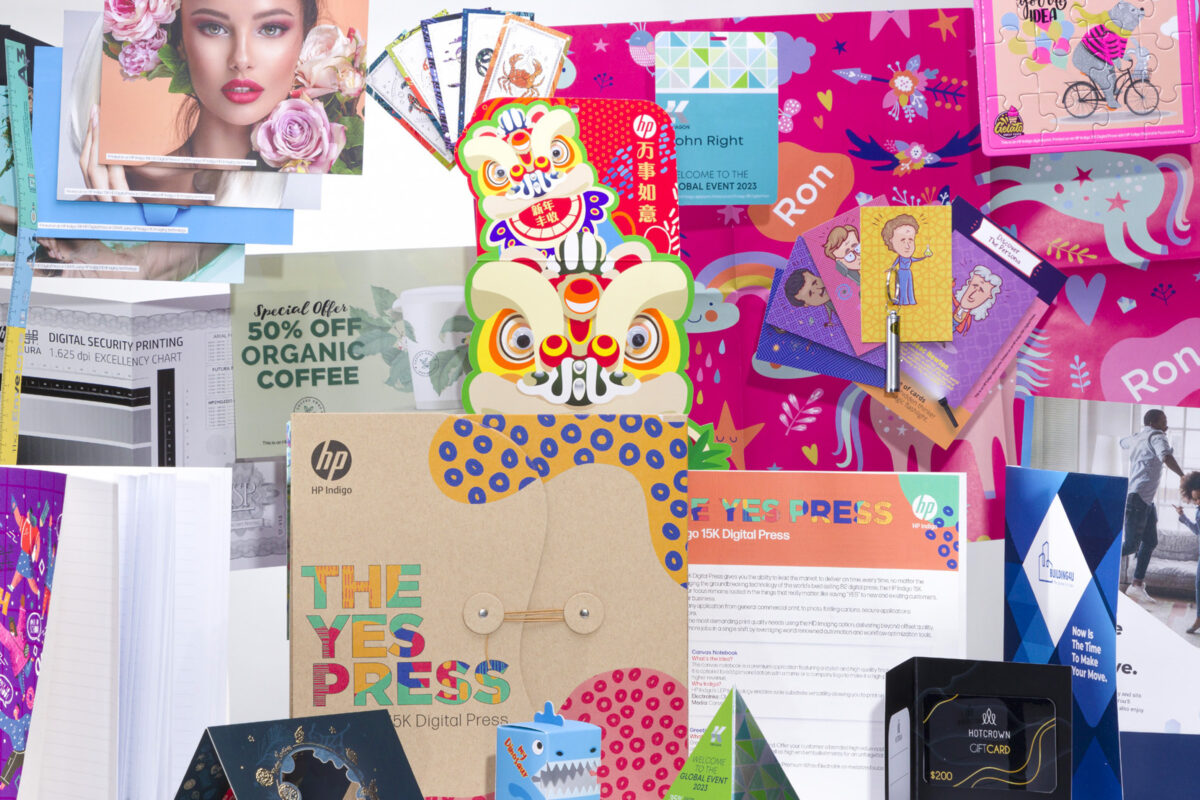

The HP Indigo 120K Digital Press processes up to 50,000 double-sided B2 sheets within 24 hours. This makes it the ideal solution for short and long jobs under deadline pressure. With machines such as the HP Indigo 18K (B2) and HP Indigo 7K (A3), a wide variety of applications can be realized: Photo products, packaging, direct mailings or folding boxes. Over 3,300 certified substrates and special inks enable high-quality, differentiated print products.

The US printing company Anstadt describes this versatility as a real game changer: the company has developed from a traditional commercial printer into a diversified provider for e-commerce, cardboard packaging, advertising displays and more - all produced digitally with HP Indigo.

Growth through partnerships and automation

HP Indigo offers more than just technology. Strategic partnerships with platforms such as Canva, Fiverr and Lightricks help customers to tap into new areas of business. For example, Blooming Color has increased its revenue by 40% in three years through these partnerships. The company also benefits from intelligent automation: error detection, automatic recovery and software-supported control via Power Packs enable hundreds of jobs to be processed with minimal effort. Brian Scott, President of Blooming Color, comments: "Thanks to our HP Indigo presses and automation capabilities, we have been able to turn micro jobs into a high-growth area. Every morning, hundreds of individual jobs are ready for production."

Future-proof through sustainable automation

HP Indigo is consistently investing in sustainable and automated printing solutions - including waste reduction systems, energy-saving processes, greener consumables and end-to-end automation with robotics.

As automation continues to advance, the future of print production is moving towards fully integrated production lines with minimal manual intervention. In this way, HP Indigo is helping printers to remain future-proof, flexible and competitive - balancing "versatility, efficiency and sustainability".

Find out more about our solutions for digital commercial sheetfed printing:

Contact us

Seizing opportunities in digital commercial sheetfed printing? Our experts will be happy to help you. Please contact us.