Labeling eggs and egg cartons

Secure coding of eggshells and packaging - traceable, food-safe and reliable

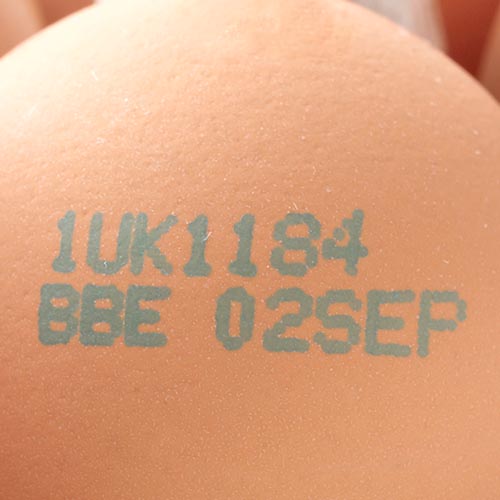

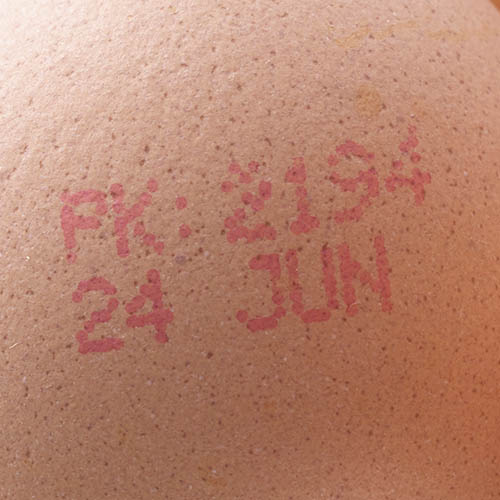

The labeling of eggs is required by law and serves to ensure traceability and product safety. Each egg shell must be marked with a producer code that provides information about the farming method, country of origin and farm number. In addition, production dates, best-before dates and batch numbers are often printed on packaging such as egg cartons. To ensure that this information is clearly legible and abrasion-resistant, specially adapted printing technologies are used that can be seamlessly integrated into existing production processes.

Get in touch with usWhy is the labeling of eggs and egg cartons important?

Ensure traceability

The coding on the eggshell enables complete traceability back to the producer. This enables a quick and efficient response in the event of product recalls or quality problems.

Visibility in retail and logistics

Not only the egg itself, but also the egg carton carries important information such as production date, best-before date or batch codes. This data ensures smooth logistics processes and makes warehousing easier.

Food safety and legal requirements

In the EU and Switzerland, the labeling of eggs is mandatory. The inks used must be food-safe, abrasion-resistant and easy to read in order to comply with legal requirements.

Challenges in the labeling of eggs and egg cartons

The marking of eggs and egg cartons places specific demands on printing technology, adhesion and legibility. The combination of sensitive shell and carton packaging in particular requires precisely coordinated systems.

Delicate eggshells

The surface of an eggshell is porous and sensitive to mechanical stress. The printing technology must work gently to avoid cracks or breaks.

High cycle rates in the sorting system

Modern egg production lines operate at speeds of up to 30,000 eggs per hour. Labeling must be reliable, accurate and without delays.

Food-safe inks and cardboard adhesion

The coding on the eggshell requires certified inks that are suitable for direct food contact. At the same time, the marking on egg cartons must remain abrasion-resistant and easy to read.

Suitable technologies

Various printing technologies are used for marking eggs and egg cartons. Gentle treatment of the sensitive shell, food-safe inks and reliable adhesion to carton packaging are crucial. The following technologies have proven themselves in practice:

Get in touch with us

Continuous Inkjet (CIJ)

Direct printing on eggshells is usually carried out using continuous inkjet systems. These enable clear, high-contrast marking that complies with legal requirements.

- Food-safe inks for direct contact

- Quick-drying and abrasion-resistant on the porous surface

- High line speed of up to 30,000 eggs per hour

Thermal Inkjet (TIJ)

Thermal Inkjet (TIJ) is not only suitable for coding on egg cartons, but also for high-resolution labeling directly on the egg shell. The technology allows detailed information such as producer codes, production data or even QR codes to be applied cleanly and precisely. The advantages lie in the fine resolution and flexibility when printing small characters and complex symbols.

- Ideal for smooth cardboard surfaces and direct labeling on eggshells

- High print quality for 2D codes, QR codes and product information

- Quick-drying, food-safe inks for clearly legible markings

- Flexible for varying content and small print images

Laser marking

Egg cartons can also be marked using a laser. Packaging made of cardboard (pulp fiber) or plastic packaging for boiled eggs is particularly suitable. Laser engraving ensures permanent, smudge-proof marking, which is particularly advantageous in automated lines. In addition, there is no need for consumables such as ink or labels.

- Permanent engraving on cardboard and plastic packaging

- Fully automated line integration into existing packaging processes

- No consumables, less maintenance

The CHROMOS way to the optimum solution

Requirements analysis

We work with you to check the specific requirements of your production line - from the line speed to the material properties of the eggshells and cartons.

Technology selection based on real conditions

Based on the analysis, we select the appropriate printing technology - whether CIJ for direct egg coding or TIJ for packaging coding. In doing so, we take into account both the legal requirements and the individual production conditions.

Test printing and process integration

We carry out test prints under real conditions and check the legibility, adhesion and food safety of the marking. We then integrate the printing systems seamlessly into your existing line.

Support and optimization

Our team accompanies the commissioning and offers you comprehensive technical support. We are also on hand to assist you with changes to your line - flexibly and reliably.

Our tip: Get advice from our experts

Whether egg trays or cardboard packaging - the right printing technology determines legibility, durability and legal compliance. Test marking in advance provides clarity and ensures that your production runs smoothly.

Get in touch with usCase study: Efficient labeling at The Lakes Free Range Egg Company

British egg producer The Lakes Free Range Egg Company has equipped its production lines with a fully automated laser marking system. In collaboration with Moba and a modern packaging line, egg cartons made of cardboard and plastic are marked permanently and abrasion-resistant - without any consumables.

The marking is carried out with precise production data directly on the packaging. The lasers are fully integrated into the five packaging lines and work seamlessly with the Moba Omnia egg graders. This has not only enabled the company to increase production capacity, but also to reduce maintenance costs.

"The laser systems have significantly improved our lines. The time and cost savings as well as the high quality and speed are a real step forward. We feel well positioned for the future."

- Mark Gaskin, Managing Director, The Lakes Free Range Egg Company

Application examples

Contact us

Our experts will be happy to help you. Get in touch with us!