Optical fill level control in production

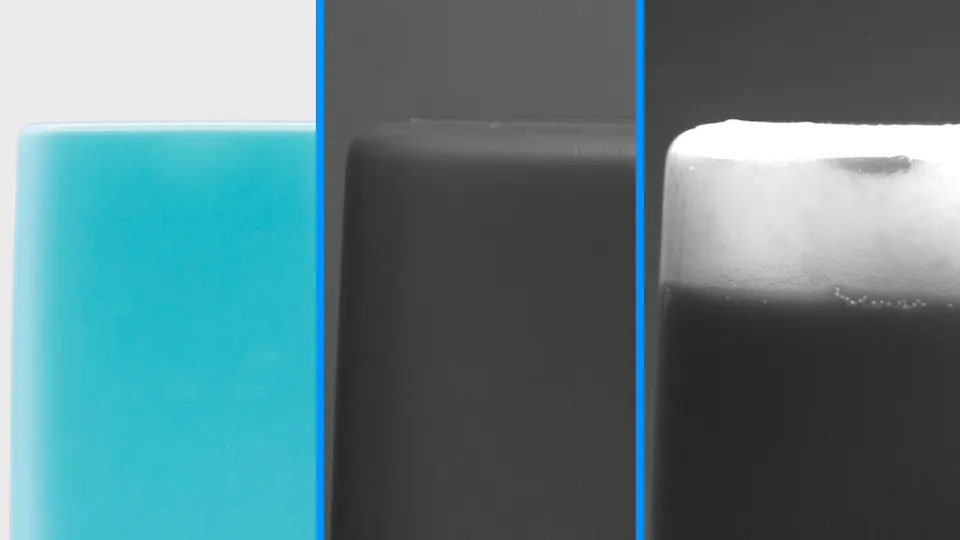

Machine vision systems reliably detect the fill level of liquids, powders or solid products - quickly, precisely and without contact.

Fill level monitoring is a central task in automated production lines. It ensures that bottles, vials, pouches or blister packs are filled correctly and completely. Optical systems based on machine vision work contact-free, deliver results in real time and can distinguish more than just "full or empty". They also check the uniformity, position and quality of the filling product - regardless of whether it is a liquid, granulate or solid product.

Get in touch with usWhy optical level control is important

Ensure quality and product safety: A correct fill level ensures that customers receive exactly what is declared. Deviations not only jeopardize satisfaction, but also compliance with regulatory requirements. Visual inspection ensures that every product meets the defined standards.

Increase efficiency: Overfilling wastes material, underfilling leads to rejects or returns. Precise control reduces losses, avoids reworking and lowers production costs in the long term.

Wide range of applications: Optical fill level inspection is not limited to liquids. Powders, granulates, tablets or blisters can also be reliably inspected. This makes it suitable for a wide range of industries - from food and pharmaceuticals to consumer goods.

Challenges in optical level control

The implementation of reliable dimension and shape control is challenging. Different materials, production speeds and environmental conditions place special demands on the systems used. Typical challenges are

Different materials and packaging

Transparent bottles, PET containers or blister packs are well suited, while opaque cans or metal packaging make visual inspection impossible. Systems must therefore be adapted to suitable packaging types.

High line speeds

In beverage and pharmaceutical production, several hundred products often move along the conveyor belt every minute. Vision systems must record and process the fill level in real time without slowing down the production flow. Short exposure times and robust algorithms are crucial here.

Variability of the filling material

Liquids can foam, powders can form uneven surfaces and tablets can slip in the blister. A vision system must be robust enough to detect such fluctuations and still provide precise information about fill level and completeness.

Suitable machine vision technologies

For optical fill level inspection, it is crucial that the product can be made visible - for example through glass bottles, PET containers or blister packs. Standard cameras reach their limits with opaque materials. In such cases, special technologies such as SWIR (short wave infrared) cameras are used, which make certain plastics permeable and can visually detect the fill level.

Depending on the product and requirements, different approaches are also available: modular industrial cameras with external evaluation, compact smart cameras for standardized tasks or 3D systems for precise volume analysis.

Get in touch with us

Industrial cameras with external processing

Deliver high-resolution images and evaluate them on an industrial PC or embedded controller - maximum flexibility, but with more integration effort.

- Freely combinable (optics, software, trigger)

- Suitable for combined tests (fill level + presence/position/seal)

- Scalable for complex lines and high cycle rates

Smart cameras

Combine camera, processor and evaluation software in one device - compact and quick to integrate for clearly defined level tasks.

- No external PC, low footprints

- Fast commissioning, standardized tools

- Ideal for stable products/containers and limited space

3D systems

Detect height or volume profiles and are suitable when topography is decisive - for example, with open products or bulk goods.

- Volume/height check independent of color/contrast

- Robust for irregular surfaces (powder mountains, baked goods, tablet layers)

- Supplements 2D if pure edge/meniscus detection is not sufficient

The CHROMOS way to the optimum solution

Analysis of requirements

We look at products, packaging and production conditions in order to define the right vision solution for the respective fill level control.

Selecting the right system class

Whether a modular industrial camera, compact smart camera or 3D system - we select the technology that fits the process reliably and economically.

Integration and adaptation

The systems are integrated into the production line in such a way that results are available in real time and flow seamlessly into control systems or documentation.

Support during operation

We provide local service, training and support to ensure that the systems deliver stable results in the long term and can be flexibly adapted to new requirements.

Contact us

Our experts will be happy to help you. Get in touch with us!