Machine vision in the food and beverage industry

Reliably automate quality control, packaging inspection and traceability

The requirements for machine vision systems in the food and beverage industry are high: hygiene standards, traceability and error-free packaging inspection are key. Whether checking fill levels, checking labels or reading codes - modern machine vision solutions make a decisive contribution to optimizing processes and ensuring product safety.

Get in touch with usWhy machine vision is important in the food and beverage industry

Reliably comply with product safety and hygiene requirements

Automated image processing helps to reliably detect contamination, damaged packaging or incorrectly positioned labels - even with varying formats and high line speeds.

Meet traceability and legal requirements

The automatic reading and checking of barcodes, data matrix codes or batch numbers enables traceability and labeling requirements to be implemented efficiently.

Making production processes more efficient and robust

Machine vision systems enable continuous inline inspection - without manual intervention. This improves process reliability and prevents faulty products from reaching the next processing step in the first place.

Challenges

The marking of batch and serial numbers places high demands on precision and production reliability. In particular, integration into existing processes and the avoidance of misprints are crucial for reliable traceability.

Different packaging formats and materials

From PET bottles and cardboard packaging to metal cans: the variety of packaging shapes and materials places high demands on lighting, image capture and evaluation.

High cycle rates and short test times

Production lines in the food industry often operate at extremely high speeds. Image processing must inspect reliably and in real time - without slowing down the line.

Strict hygiene and cleaning requirements

All components used must either be positioned outside the hygiene area or designed to withstand the cleaning processes.

Typical applications in the food and beverage industry

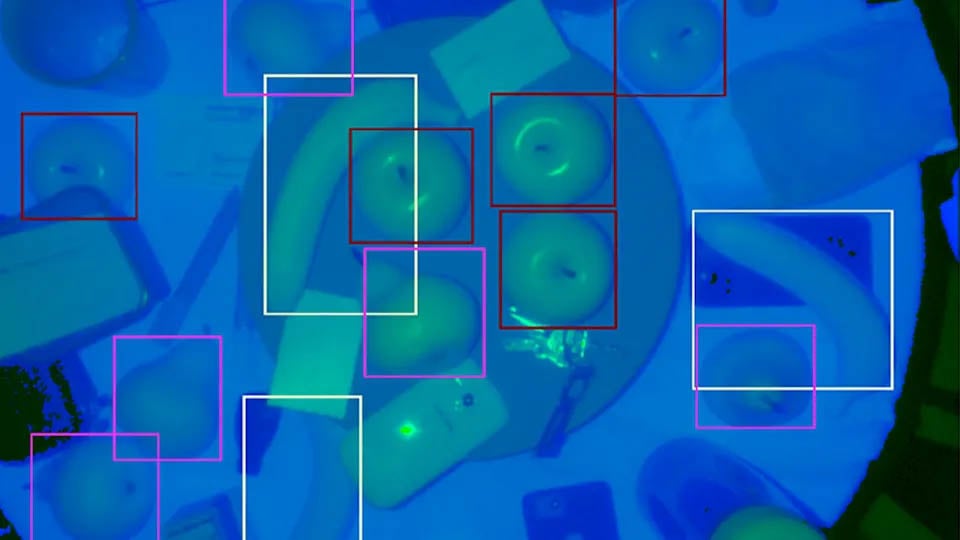

Whether packaging, label or contents - machine vision systems record critical features inline and in real time. This allows errors to be detected at an early stage and processes to be safeguarded efficiently. The following applications are particularly common in the food and beverage industry:

Fill level control

Camera systems check inline whether containers are filled correctly - regardless of shape, volume or transparency. Reliable detection is possible even at high line speeds.

Label and packaging control

Image processing systems record the position, content and legibility of labels and packaging. This allows incorrect placement, incorrect varieties or faulty batches to be detected at an early stage - even before they reach the point of sale.

Quality and integrity check

Cameras detect damage, leaks or missing components - for example on sealing surfaces, lids or film packaging. Visual features such as colour deviations or product residues can also be automatically detected, sorted or ejected.

Code reading and traceability

Machine reading and validation of barcodes, data matrix codes and best-before dates enables consistent traceability - even with varying formats and print qualities.

Suitable camera technologies

High cycle rates, changing packaging formats and strict hygiene requirements come together in food and beverage production. For image processing solutions to function reliably, the cameras and components used must be carefully selected - tailored to the application, environment and level of integration.

Get in touch with us

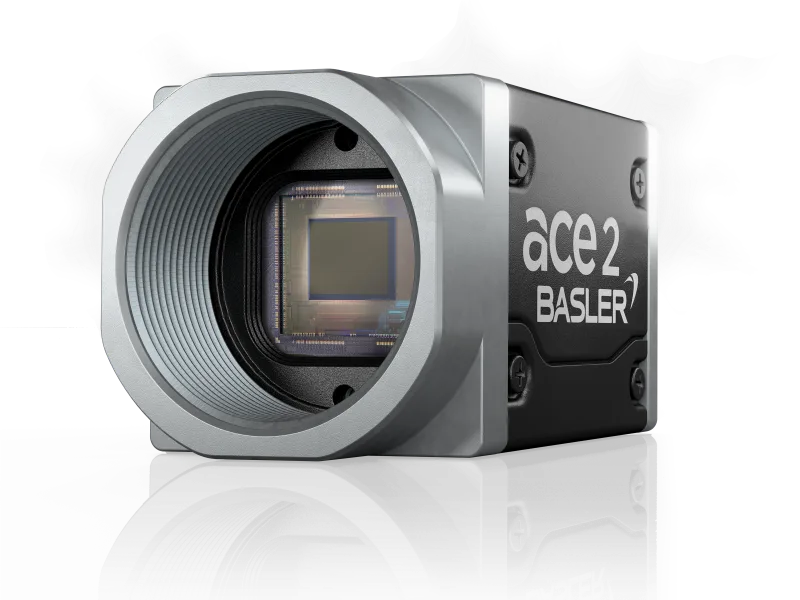

Compact industrial cameras with a high frame rate

Bottle inspection, fill level control or label inspection often require high resolutions and fast image processing - even where installation space is limited.

- GigE, USB3 or CoaXPress, depending on the integration environment

- Global shutter for precise shots during movement

- CMOS sensors with high light sensitivity

- Optional: NIR, SWIR or UV cameras for special applications

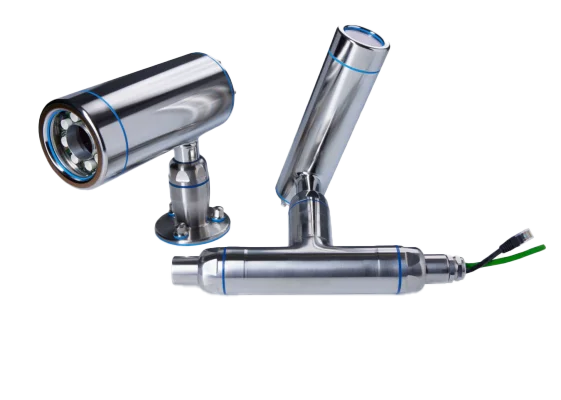

Hygienic components and protective housing

In open or damp production environments, cameras must either be installed outside the cleaning area or protected accordingly.

- Protective housing with IP65/IP67 protection

- Stainless steel or anodized housing for aggressive cleaning agents

- Cut-off wheels and compressed air flushing in direct proximity to the line

- Temperature-stable solutions for refrigerated production areas

Matching lenses

The lens influences image quality, sharpness and field of view - and must be precisely matched to the camera, working distance and object size.

- Robust C-mount lenses for industrial environments

- Fixed focal lengths with locking mechanism to prevent misalignment

- Telecentric lenses with high accuracy

- Selection depending on sensor size and resolution

Lighting

Lighting direction and type of illumination determine contrast, recognizability and testability. The right lighting is crucial for stable results.

- Incident light, transmitted light, line or ring lighting

- Homogeneous diffuse illumination for glossy surfaces

- Wavelengths in the visible or near IR range

- Triggerable high-power LEDs for fast cycles

Software for automatic evaluation

Whether for code inspection, label reading or position detection: image processing software with predefined inspection tools enables typical applications to be implemented quickly - and can be flexibly integrated into existing systems.

Learn more

The CHROMOS way to the optimum solution

Requirements analysis and feasibility test

Every application in food and beverage production has its own requirements - depending on the packaging, product shape, speed and test environment. We analyze your task and test the technical feasibility under realistic conditions.

Component selection and test setup

Based on your objectives, we put together the right camera, optics, lighting and evaluation software. We simulate the test process in laboratory setups and optimize the detection - for robust results with changing products and batches.

Integration into existing processes

Image processing is seamlessly integrated into existing lines - whether in continuous packaging processes, at transfer points or in interaction with handling systems. Results can be transmitted directly to control systems or documented.

Support during operation and in the event of changes

We continue to support you even after commissioning - with adaptations for product changes, optimizations during operation or support for software, interfaces and data evaluation.

Contact us

Our experts will be happy to help you. Get in touch with us!