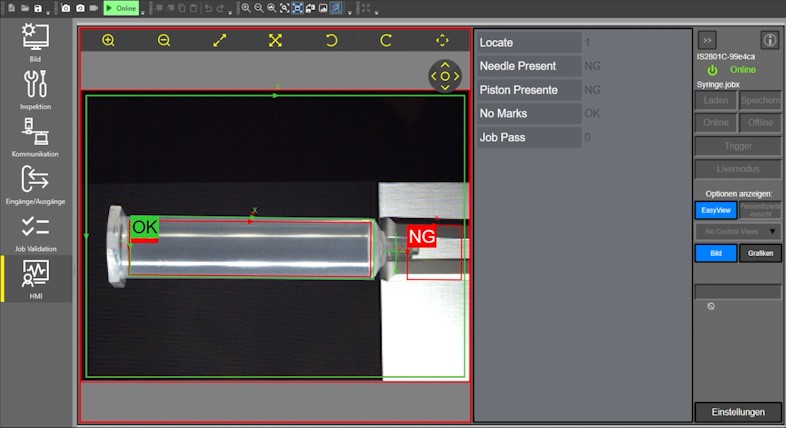

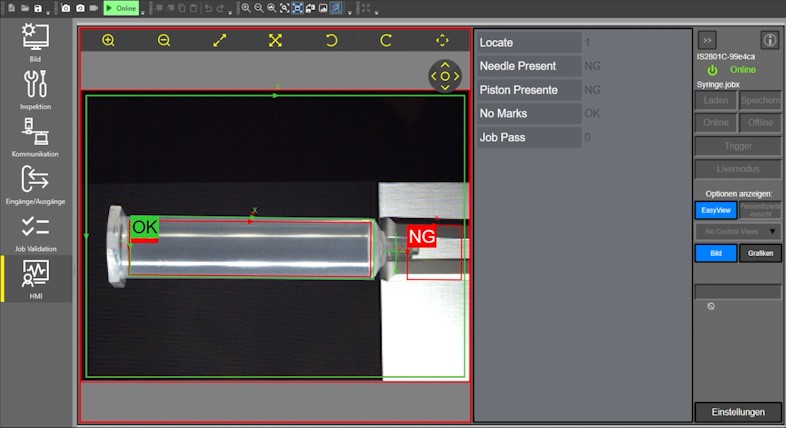

Visual completeness check in production

Machine vision systems ensure that all parts are present, correctly positioned and undamaged - reliably and inline.

The completeness check is one of the central tasks of automated quality assurance. It involves more than just counting parts: Machine vision systems check whether all the intended elements are present, correctly arranged and in perfect condition. In this way, blister packs in the pharmaceutical industry, product sets in the consumer goods sector or assemblies in assembly can be monitored seamlessly. The result is stable processes, fewer rejects and consistently high product quality.

Get in touch with usWhy the visual completeness check is important

Ensure quality and safety: Missing or incorrectly positioned parts can lead to malfunctions, safety risks or complaints. A visual completeness check ensures that every product meets the specifications and functions reliably.

Efficiency and cost control: Errors that only become apparent at the end of the line or at the customer's premises cause rework, rejects and additional costs. Inline inspections with machine vision detect deviations immediately and enable quick corrections to be made in the process.

Versatile application options: Whether blister packs in the pharmaceutical industry, sets in the consumer goods sector or assemblies in assembly - vision systems can be flexibly adapted to different products and packaging types. This means that the completeness check covers a wide range of applications.

Challenges in the optical completeness check

The optical completeness check sounds simple at first glance, but often proves to be complex in practice. Different products, packaging and production conditions place high demands on cameras, optics and algorithms. For systems to work reliably, they must be robust against disruptive factors and deliver precise results even at high cycle rates.

Variety of products and packaging

From transparent blisters and cardboard packaging to complex assemblies - each variant places different demands on image capture and evaluation. Systems must be flexibly configurable in order to reliably cover different formats.

Detection of small or similar parts

In pharmaceutical or electronics applications, components often differ only minimally in shape, color or size. High resolution and stable algorithms are required for systems to reliably detect these differences.

Production conditions in the line

Reflections, changing light conditions, overlapping or obscured parts can make detection difficult. Vision systems must be robust against these disruptive factors in order to deliver reliable results under real conditions.

Suitable machine vision technologies

Completeness checks require systems that work reliably and flexibly. Depending on the product and requirements, different approaches are used - from classic industrial cameras to compact smart cameras and 3D systems. AI-supported processes also play a supplementary role today when conventional image evaluation reaches its limits, for example in the case of varying surfaces or components that are difficult to distinguish.

Get in touch with us

Industrial cameras with external evaluation

For variable products and formats: Camera + optics provide the images, the evaluation runs on an industrial PC or controller. Maximum flexibility for extensive inspections.

- Freely configurable (resolution, optics, algorithms)

- Combined checks: Presence, position, orientation, integrity

- Scalable for multiple cameras, large image fields and high cycle rates

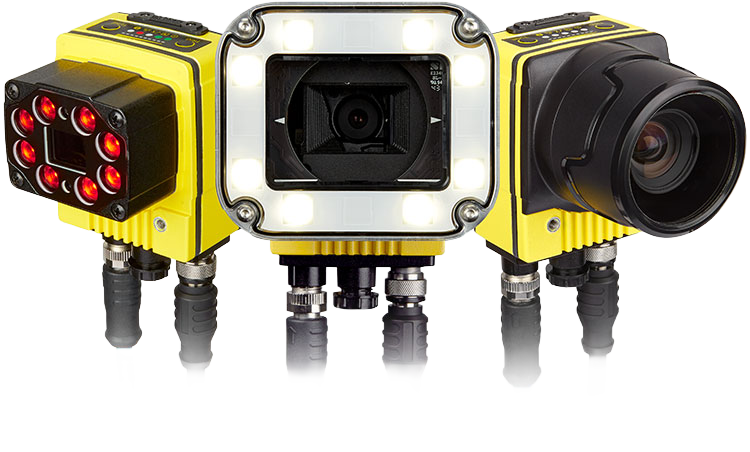

Smart cameras

All-in-one devices with integrated evaluation. Ideal when layouts are clearly defined (e.g. blisters, sets) and fast integration is required.

- No external PC, low footprints

- Fast commissioning with standardized tools

- Stable with recurring formats and fixed tolerances

3D systems

When height and depth are relevant: 3D captures Z information and recognizes missing/twisted parts even with complex geometries.

- Checks position, stacking heights and distances in Z

- Robust with uneven backgrounds and overlays

- Suitable for assemblies, plug connections and assembly stations

AI-supported processes

Supplement classic image processing when parts differ only minimally or vary greatly.

- Recognizes subtle differences in shape, color, texture

- Robust with layer variations, partial coverings and mixed assortments

- Can be adapted to new variants with practical data

The CHROMOS way to the optimum solution

Analysis & feasibility

We test products, formats and tolerances and carry out preliminary tests to determine which vision technologies offer the greatest benefits. In this way, we ensure that the solution is reliable and economical.

System selection and test setup

Cameras, optics, lighting and software are optimally combined and tested in test environments. This ensures that the completeness check remains stable even with changing products.

Integration into the production line

Our systems can be seamlessly integrated into PLCs, databases or process control systems. Results are available in real time and can be used for documentation and traceability.

Support during operation

We provide assistance with product changes, process optimization and ongoing operation - with local service, support and training for your team.

Contact us

Our experts will be happy to help you. Get in touch with us!