FGF Pellet 3D printer (Fused Granulate Fabrication)

Large format printing with high material efficiency, short cycle times and low operating costs.

FGF 3D printers (Fused Granulate Fabrication) enable direct 3D printing with thermoplastic granulate - completely without filament or powder. The process is particularly suitable for large, robust components with high unit weights or volumes.

Typical areas of use are applications where speed, cost control and material flexibility are important - for example in mechanical engineering, model making, architecture or structural prototypes.

Compared to other 3D printing processes, FGF systems score points for their high throughput, low material costs and the ability to process recycled or special granulates.

Get in touch with usFGF 3D printer from WASP

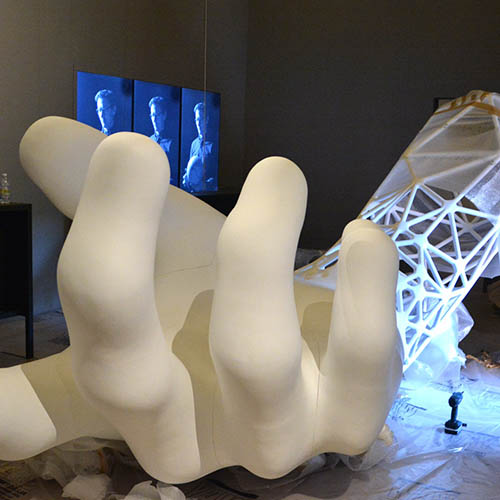

WASP is a pioneer in large-volume 3D printing with granules. The Italian systems combine industrial performance with sustainability and are particularly suitable for architecture, design, research and art. With open system architecture, heating chamber technology and the ability to process recycled or bio-based materials, WASP offer maximum flexibility for big ideas.

Get in touch with us

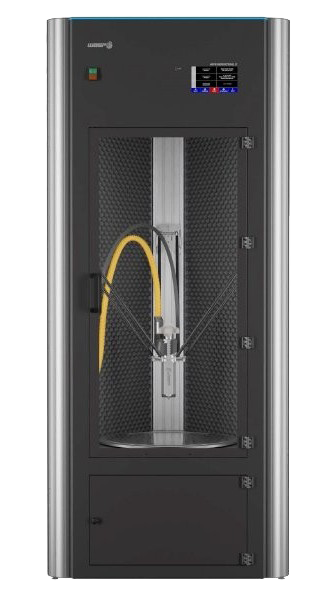

WASP 4070 HDP

The WASP 4070 HDP is a compact, industrial-grade granule printer for anyone who wants to produce large components in a limited space. With a closed build chamber, active build plate control and filter system, it offers clean and stable operation - ideal for research, laboratories or pilot production.

- Special features: Vacuum building plate control, HEPA filter, closed installation space

- Installation space: Ø 400 × 600 mm

- Extruder temperature: up to 350 °C

- Throughput: up to 350 g/h

- Granulate container: 5 L

from CHF 21'000.00

Find out more about the WASP 4070 HDP

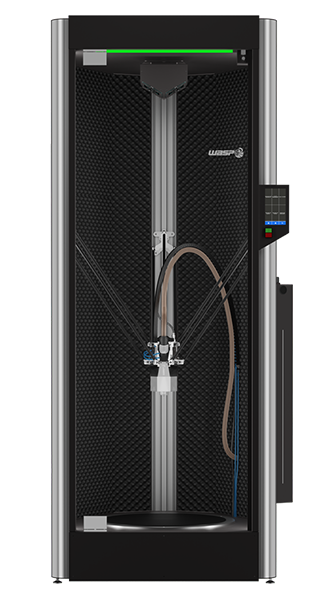

WASP 60100 HDP

The WASP 60100 HDP is aimed at users who want to process larger volumes and more demanding materials. The combination of a liquid-cooled high-temperature extruder and FIRECAP heating chamber allows uniform temperature control - even for long print jobs and technical plastics.

- Installation space: Ø 600 × 1000 mm

- Extruder temperature: up to 500 °C (liquid-cooled)

- Throughput: up to 500 g/h

- Granulate container: 35 L

- Special features: FIRECAP heating chamber, HEPA filter, closed system

WASP 3MT HDP

The WASP 3MT HDP is made for applications on a very large scale. With an installation space of one cubic meter, it is predestined for architecture, mould making or large-volume prototypes. The robust mechanics, powerful heating system and quiet operation make it the first choice for large-scale creative projects.

- Installation space: Ø 1000 × 1000 mm

- Extruder temperature: up to 350 °C

- Throughput: up to 2 kg/h

- Granulate container: 20 L

- Special features: FIRECAP heating chamber, brushless motors, quiet operation

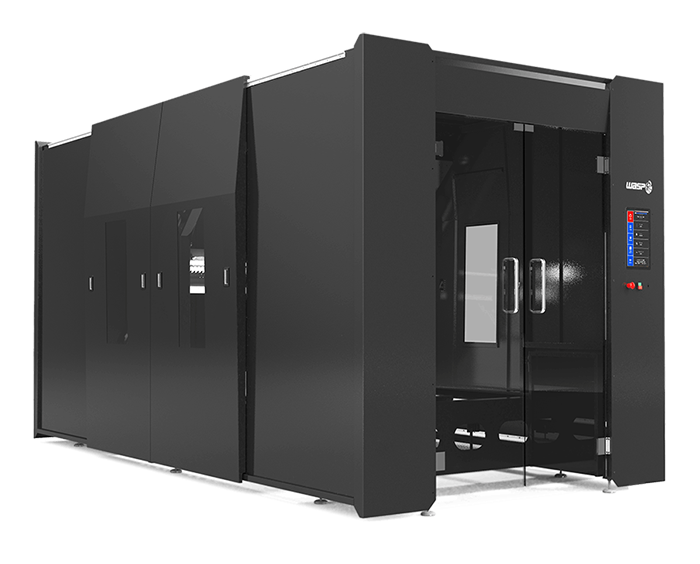

POWER WASP 45 HDP

The POWER WASP 45 HDP is designed for industrial applications with large volumes. With an installation space of up to 1.5 × 1.1 × 1 m, it is ideal for prototypes, molded parts or furniture. The 45° printing technology, heated chamber and automatic pellet drying ensure reliable results with a high degree of material freedom.

- Installation space: 1,500 × 1,100 × 1,000 mm

- Extruder temperature: up to 350 °C

- Layer height: 0.5 - 3 mm

- Throughput: up to 2 kg/h

- Granulate container: 20 l

- Special features: 45° print head, FIRECAP heating system, vacuum bed

FGF 3D printer from YIZUMI

The SpaceA series from YIZUMI offers modular, robot-assisted FGF systems for industrial applications. With KUKA robots, screw extruders and integrated controllers, they enable direct printing with thermoplastic pellets - ideal for the production of large-format components. The series comprises three models that differ in size, throughput and degree of automation.

Get in touch with us

SpaceA S-Line

The S-Line is the compact entry-level model of the SpaceA series - a fully equipped plug-and-play system with KUKA robots from 0.9 to 2.5 m. Thanks to its fixed table, integrated material handling and controller, it is mobile and ready for immediate use - without additional software, set-up or accessories.

- All-in-one: incl. dryer, conveyor, extruder, robot, software

- Plug-and-play: mobile, no foundation required

- Modular: Extruder & automation can be expanded later

- Throughput: approx. 3.5-10 kg/h (depending on extruder)

SpaceA B-Line

The B-Line is the industrial solution for large-format FGF applications. With KUKA arms from 1.6 to 3.9 m and powerful extruders (up to 20 kg/h), it is ideal for large-volume components, high capacity utilization and series-like processes.

- Long reach, high extrusion performance

- Three extruder variants with up to 20 kg/h

- Operation via Beckhoff HMI

- Fixed table, open working environment

- Ideal for series production and high unit weights

SpaceA C-Line

The C-Line is based on the S- or B-Line and can be individually expanded - for example with milling units, camera systems, automatic parts feeding or sensor technology. It is aimed at companies with high demands on process integration, automation and individualization.

Special features:

- Maximum adaptability for hybrid and series processes

- Individual configuration according to customer specifications

- Combination of printing & milling possible

- Fully automated production cells with sensors, cameras and more

What makes FGF 3D printers stand out?

Direct printing with industrial granulate

Instead of filament, FGF works directly with plastic granulate - the same raw material used in injection molding. This significantly reduces material costs and opens up new possibilities in the choice of materials.

High throughput & large components

FGF printers are built for speed and volume. Large nozzles, powerful extruders and massive build platforms enable the printing of large-format objects - efficiently and economically.

Robust technology for harsh environments

The systems are designed for industrial conditions: robust construction, powerful material handling and easy maintenance make them ideal for use in workshops, laboratories and production environments.

Challenges when using FGF 3D printers

As convincing as the advantages of FGF are, the process also places special demands on the technology, environment and material. Those who know and take these into account will benefit from an efficient and economical production process.

Material feed & extrusion

Granulate printing requires constant, reliable feeding. Moisture or uneven granulation can impair the print quality.

Space requirement & environment

FGF printers require more space than typical desktop devices - also for component handling and post-processing.

Limited detail resolution

The process is designed for large, stable structures. FGF is only suitable for fine details to a limited extent.

Not all granules are the same

Not every material works without problems. Flow behavior, additives and composition must match the machine.

???? YIZUMI SpaceA in use

Nikolai Lamat, Business Unit Leader Additive Manufacturing at Yizumi Germany, provides insights into the development and industrial strength of the SpaceA system.

Find out how SpaceA emerged from a research project at RWTH Aachen University and is now successfully used worldwide in the automotive industry, especially for structural components for luxury vehicles - thanks to a wide variety of materials, scalability and international system integration.

The CHROMOS way to the optimum solution

Understanding requirements

We analyze your requirements precisely - from the desired component size to material properties and throughput. We also include the production environment in the planning.

Propose technology and solution

Based on the analysis, we select the right 3D printing technology and the optimal device. We plan the entire process together - including material selection and post-processing.

Test feasibility

Our technicians will set up your 3D printer and ensure optimal configuration. We offer training for your team on request.

Integration and support

We are also there for you after the purchase - with reliable support, material replenishment and technical assistance.

Our tip: Get advice from our experts

Not every 3D printer is suitable for every application - and not every printing technology is ideal for all materials, component sizes or production requirements.

We help you to find the perfect solution for your projects - precise, efficient and optimally tailored to your requirements.

Contact us

Our experts will be happy to help you. Get in touch with us!