SLS 3D printers impress with many advantages

SLS stands for Selective Laser Sintering. In contrast to the SLA process, no liquid mass is hardened here, but polymer powder is fused in very fine layers. A major advantage of this technology is the fact that no support structures are required.

SLS 3D printers are suitable for companies that want to manufacture customer-specific products or require functioning prototypes. Thanks to the excellent mechanical properties of the materials, it is also possible to produce ready-to-use finished parts.

THE ADVANTAGES OF THE SLS PROCESS AT A GLANCE

- Works without support structures

- Very high resolution

- Movable, connected parts possible

- Non-fused material can simply be recycled.

- Simple post-processing

- Low printing costs per unit

- Outstanding material properties

SINTERIT 3D PRINTER

The SLS 3D printers from Sinterit reliably print the finest structures and coherent, moving parts. Thanks to the advanced process, no support structures are required.

Sinterite Lisa X

CHF 24'189.00 plus VAT. The new and compact SLS 3D printer from Sinterit offers an exceptionally high printing speed and a very large build volume.

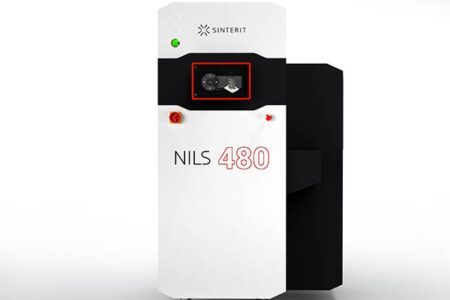

Sinterite NILS 480

CHF 65'989.00 plus VAT. The Sinterit NILS 480 is the new standard for industrial SLS 3D printing

Sinterit Lisa Pro

CHF 18'139.00 plus VAT. The Sinterit Lisa Pro impresses with its excellent price/performance ratio.

Sinterite Lisa

12'639.00 CHF plus VAT. The user-friendly desktop SLS 3D printer from Sinterit

SINTERITE AS A SET

Get your Sinterit products in one of our sets and benefit from advantageous conditions. We offer different configurations for the diverse requirement profiles of our customers.

Sinterite Entry Set

17'039.00 CHF plus VAT. Sinterit Lisa 3D printer entry set with many accessories.

Sinterit Industrial Set

94'589.00 CHF plus VAT. The Sinterit Industrial Set with the NILS 480 and the matching accessories for the best workflow.

Sinterit Performance Set

47'289.00 CHF plus VAT. The set for maximum desktop performance with the Sinterit Lisa X and the most powerful accessories.

Sinterite Open Set

30'789.00 CHF plus VAT. Sinterit Lisa Pro SLS 3D printer in Open Set with many accessories.

SINTERIT ACCESSORIES

With our accessories for your Sinterit printer, you can take post-processing and material handling in your SLS printing workflow to a new level.

Sinterit sandblaster SLS

1'749.00 CHF plus VAT.

The Sinterit SLS sandblaster for even better cleaning of your 3D objects.

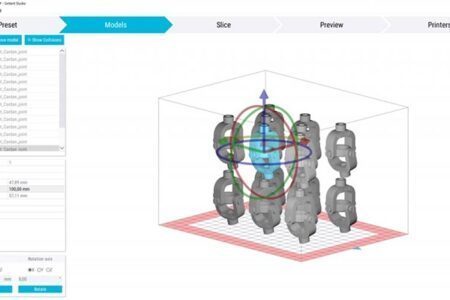

Sinterit Studio Software

The software for your Sinterit SLS 3D printer.

Sinterit Powder Handling Station

11'539.00 CHF plus VAT.

Efficient and clean post-processing and powder recovery.

Sinterit powder tool set

from CHF 539.00 plus VAT.

Special tools for the entire printing process.

Sinterit ATEX vacuum cleaner

3'839.00 CHF plus VAT.

The safe and powerful vacuum cleaner from Sinterit.

Sinterit machine frame

539.00 CHF plus VAT.

Sinterit machine frame for even more flexibility.

Sinterite powder sieve

2'739.00 CHF plus VAT.

Sinterit powder sieve for processing used powder.

Sinterit sandblaster

869.00 CHF plus VAT.

The Sinterit sandblaster for cleaning and finishing your 3D objects.

CONTACT

Our experts will be happy to help you. Get in touch with us!