YIZUMI SpaceA Series

High-performance FGF 3D printing technology for industrial production

The YIZUMI SpaceA series sets new standards in industrial production with its advanced Fused Granulate Fabrication (FGF) technology. Designed for demanding production environments, the S-Line, B-Line and C-Line models enable companies to scale efficiently from one-offs to mass production. Thanks to the use of thermoplastic pellets, the SpaceA series offers a cost-effective, high-quality production option. With the ability to shorten production cycles, expand material selection and make manufacturing processes more flexible, the SpaceA Series is the key to optimizing your production - from complex components to integration into existing lines.

Get in touch with us

The advantages of the SpaceA series at a glance

With its innovative FGF technology, the SpaceA series offers adaptability and efficiency that transforms modern production environments. Scalability, automation potential and a wide range of materials are the cornerstones of these advanced 3D printing systems.

Scalability

- Supports various robots

- Modular concept for easy scalability and customization

- Supports complex 3D designs

Automation potential

- Integration of AM processes into established process chains

- High potential for process combinations and economic benefits

- Fully automated production approach

Variety of materials

- Use of thermoplastic pellets

- Low costs

- Easy availability

- Already certified materials (PA, PP, PMMA, PPA, PC, ...)

Productivity

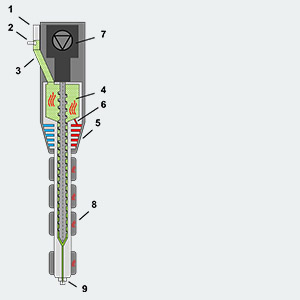

- Screw extrusion approach

- Throughput is scalable by varying revolutions per minute (RPM)

- Up to 28 times higher throughput compared to standard FLM

The SpaceA series stands for future-oriented production that is defined by maximum efficiency and adaptation to a wide range of production requirements. With FGF technology from YIZUMI, you are making an investment that is characterized by scalability, automation and a wide range of materials and takes your production to the next level.

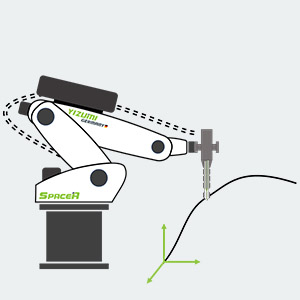

SpaceA S-Line: Maximum flexibility in a compact format

The SpaceA S-Line defines the standard for all-in-one 3D printers and offers impressive flexibility for a wide range of manufacturing tasks with KUKA arm sizes from 0.9 to 2.5 meters. This series is characterized by a complete feature set that includes the following:

- Material dryer for optimum preparation of the print material,

- Material conveyor for continuous material flow,

- Screw extruder for high print quality and speed,

- Industrial robots for precise and repeatable movements,

- Integrated control and software package for easy operation.

The compact and flexible design of the S-Line makes it possible to set up these systems almost anywhere without the need for a fixed installation. Thanks to the plug-and-play solution, production can begin immediately once the system has been moved to the desired location using a pallet truck. This makes it much easier to start or expand production, as neither fixing the system nor additional accessories or software are required.

The modular design of the S-Line makes it possible to adapt the system to changing production requirements even after the initial installation. For example, the extruder can be upgraded from a throughput of approx. 3.5 kg/h to up to 10 kg/h or a conveyor belt can be integrated to increase the level of automation of the system for series processes.

Get in touch with us

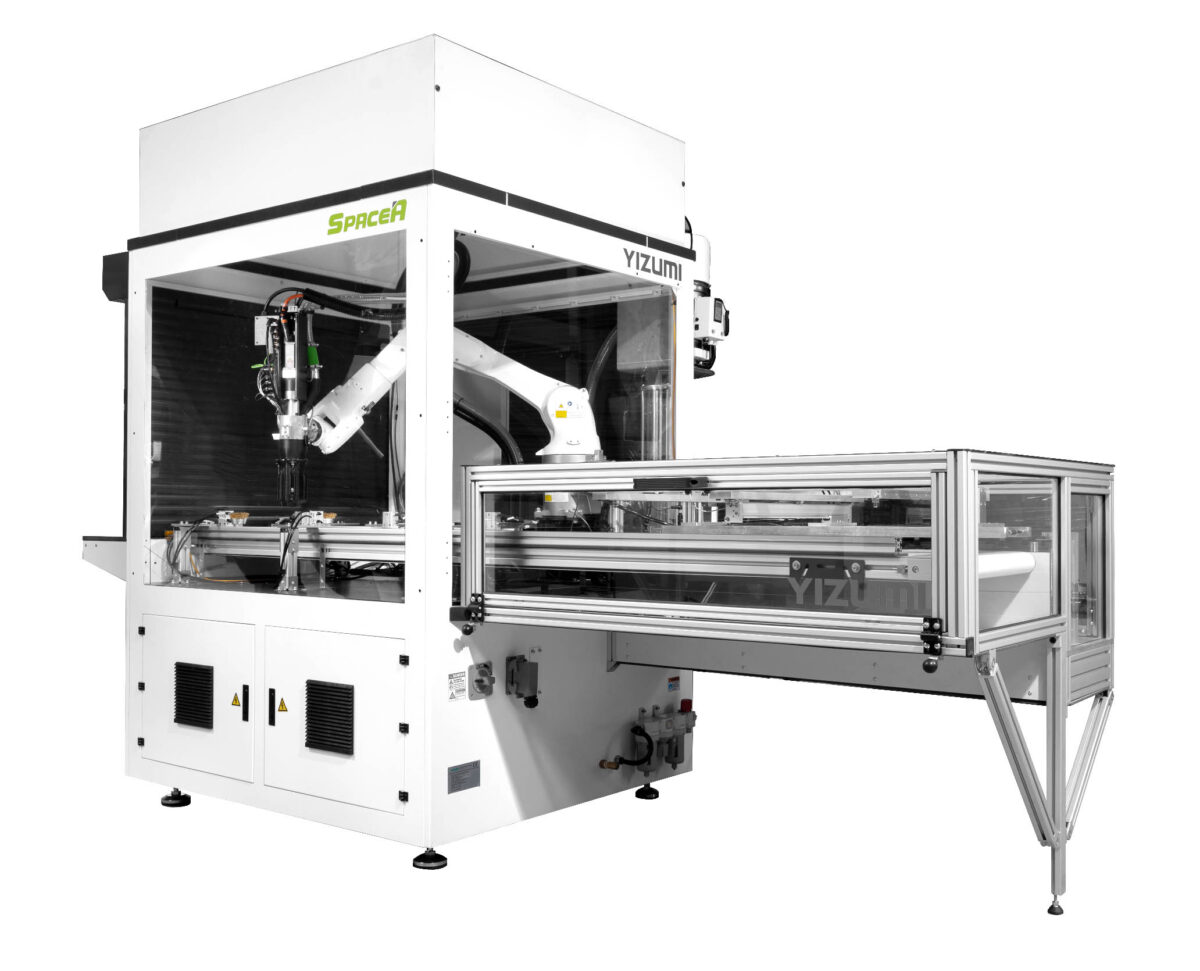

SpaceA B-Line: The large-format solution for demanding production requirements

The SpaceA B-Line expands the range of FGF 3D printers with a powerful solution for large-format and high-volume production tasks. With a KUKA arm reach of 1.6 to 3.9 meters, the B-Line is ideal for the production of large components and offers an exceptional combination of speed, precision and throughput. The outstanding features of the B-Line include:

- High throughput: Thanks to its advanced extrusion technology, the B-Line enables a throughput of up to 20 kg/h, which ensures fast production of large-format components.

- Freely accessible production cell: The open design facilitates access and handling of the produced parts, which increases efficiency in the production process.

- Wide range of applications: Thanks to its long reach and high throughput, the B-Line is particularly suitable for industries that require large, complex components with a high material density.

- Complete solution: The B-Line is supplied as a complete system, including material dryer, material conveyor, screw extruder and industrial robot, controlled by an intuitive software package.

The SpaceA B-Line stands for innovation and productivity in large-format 3D printing production. It is specially designed for companies that do not want to compromise in their production and are looking for a robust, reliable solution for the production of large-volume components. With the B-Line, you can rely on efficiency and precision to achieve your production goals and set new standards in your industry.

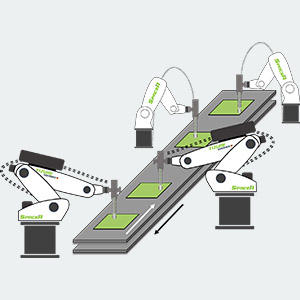

Get in touch with usSpaceA C-Line: Tailor-made machining centers for the highest demands

The SpaceA C-Line represents the pinnacle of customization and automation within YIZUMI's SpaceA series. Designed to meet specific, highly complex production requirements, the C-Line offers a fully customizable solution that can be seamlessly integrated into existing manufacturing processes. Characteristic features of the C-Line include:

- Fully automated production: By integrating advanced control systems and automation technologies, the C-Line enables an end-to-end automated production process from the material feed to the finished component.

- High degree of customization: The C-Line is configured based on the specific needs and requirements of each customer, allowing precise adjustment to individual production targets.

- Expandable process integration: In addition to 3D printing, further processing steps such as post-processing, quality control and assembly can be integrated into the C-Line, providing an efficient complete solution for production.

- Proven YIZUMI quality and reliability: Like all SpaceA models, the C-Line also benefits from YIZUMI's many years of experience in the development and manufacture of production technology, which guarantees the highest quality and operational reliability.

With the SpaceA C-Line, YIZUMI is targeting companies that do not compromise on manufacturing technology and want to expand their production capacity with a highly customizable, automated and efficient solution. The C-Line represents the future of manufacturing - a future defined by innovation, precision and adaptability.

Get in touch with us

Contact us

Our experts will be happy to help you. Get in touch with us!