Desktop Metal Studio System 2

Print metal parts in 3D in your office in just 2 steps - Print. Sinter.

Discover the Desktop Metal Studio System 2 - your ticket to the world of office-friendly metal 3D printing. This innovative system revolutionizes the prototyping process and opens new doors for design and manufacturing. With its unique combination of Fused Filament Fabrication (FFF) and Metal Injection Molding (MIM), the Studio System 2 enables the fast and efficient creation of prototypes of various designs. Immerse yourself in the next generation of metal fabrication - convenient, powerful and right in your office.

Office-friendly design

The Studio System™ 2 is the world's first metal 3D printing system designed specifically for office use. It requires no solvents or loose metal powder, eliminating the need for additional ventilation or respirators.

Innovative technology

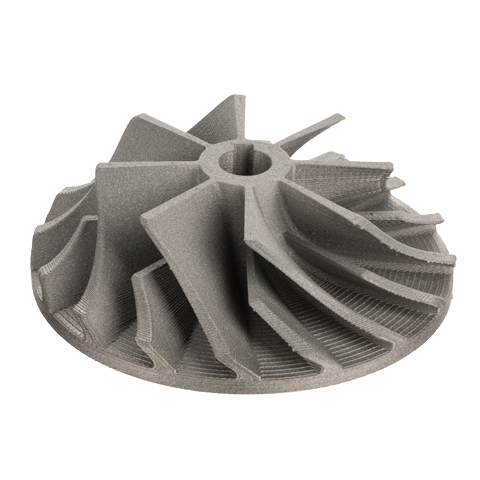

The system uses a unique combination of fused filament fabrication (FFF) and metal injection molding (MIM) to print high-quality metal parts. This technology enables high precision and attention to detail.

High parts quality

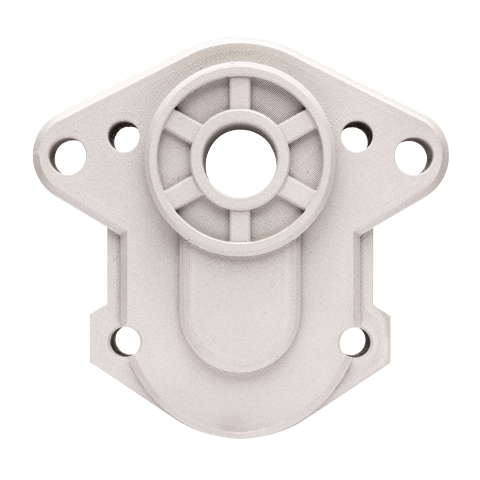

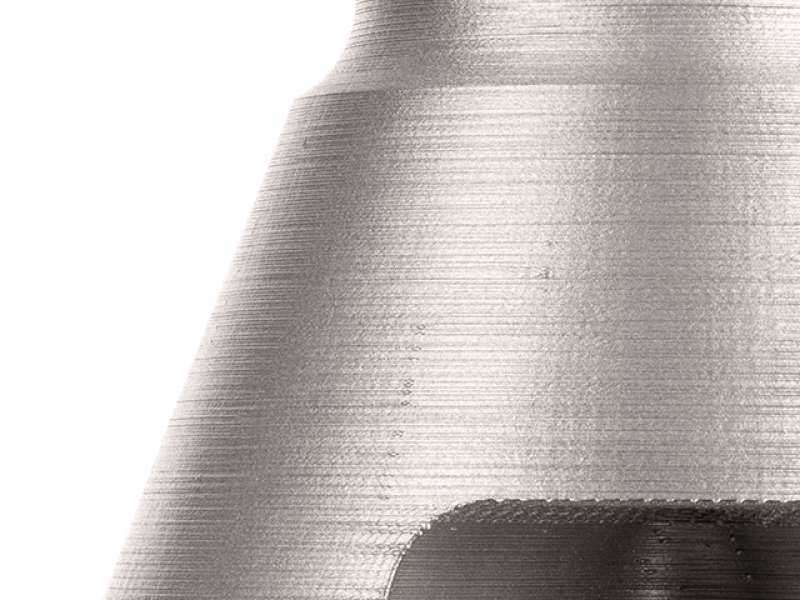

The Studio System™ 2 delivers metal parts of high quality and precision. It enables the production of robust and durable parts that can realize even the most complex geometries with improved surface quality and reduced step formation on the side walls

Two-step process

The Studio System™ 2 uses a simplified two-step process. Printed parts are placed directly into the oven, no solvent debonding is required. This makes the process more efficient and user-friendly.

Customizable printing options

The system allows you to choose between a 250µm and 400µm print head to prioritize print speed or level of detail. The layer height can be set between 50µm and 300µm, depending on the part size and level of detail.

Simple support structures

The Studio System™ 2 features the second generation of "Separable Supports" support structure technology. This makes it possible to print complex geometries with greater reliability and to remove the support structures more easily after the printing process. This results in higher print quality and more efficient post-processing of parts.

Components of the Desktop Metal Studio System 2

3D printers

Unlike laser-based systems, where metal powder is selectively melted, the Studio System 2 uses bonded metal rods, similar to an FDM printer. This eliminates many of the safety requirements often associated with metal 3D printing and opens up new possibilities, such as the use of closed-cell infill material for lightweight strength.

Learn more

| Building volume | 30 x 20 x 20 cm (12 x 8 x 8 in) |

| Print head | 250 around high-resolution nozzle, 400 around standard resolution nozzle |

Sintering furnace

The Studio System 2 furnace was designed to be the most user-friendly sintering furnace. It first heats the parts to remove all binders and then raises the temperature almost to the melting point to provide industrial-grade sintering in an office-friendly package. Pre-programmed temperature profiles matched to each part and material ensure uniform heating and cooling without the stresses that can occur with laser-based systems.

Learn more

| Retort size | 30 x 20 x 17cm (12 x 8 x 6.7 in) |

| Peak temperature | 1400°C (2552°F) |

| Surroundings | Argon, argon-hydrogen mixture, inert vacuum sintering |

Printing process

The printing process with the Desktop Metal Shop System consists of three steps. These enable the efficient production of high-quality metal parts with complex geometries and excellent mechanical properties. The process is precise, reliable and offers high reproducibility of the printed parts.

- Preparation: The secure, web-based software creates construction plans from STL or CAD files and automatically generates fixtures and control parameters based on the geometry and material of the parts.

- Printing: A workpiece is created layer by layer by extruding bonded metal rods. This involves metal powder that is held together by polymer binders. This process is called Bound Metal Deposition™.

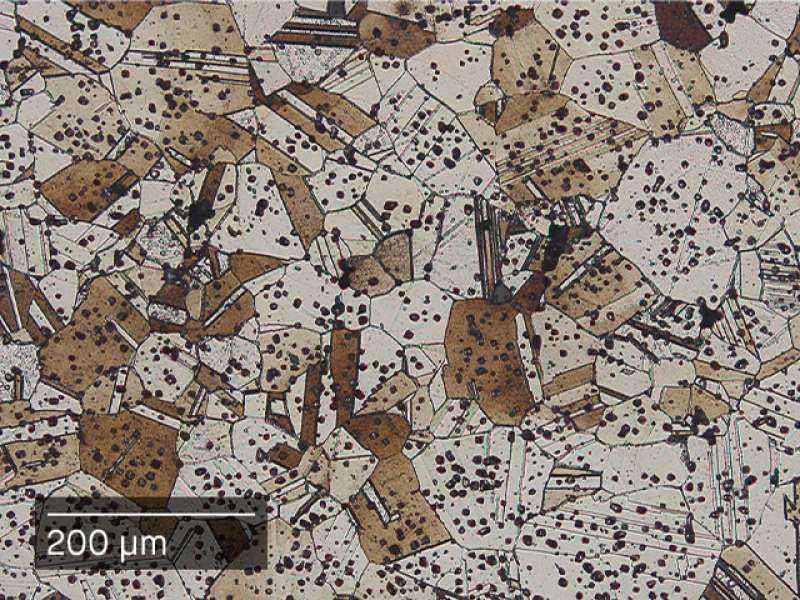

- Sintering: After printing, the workpiece is placed in the oven. When the part is heated to temperatures close to the melting point, the binder is removed and the metal particles fuse together, allowing the part to achieve a densification of up to 98%.

Advantages

Simple, two-stage processing

Manufacturing sophisticated and high-performance metal parts has never been so straightforward. The Studio System 2 revolutionizes this process with its innovative two-stage process, advanced separable fixtures and a fully software-controlled workflow. This enables unprecedented simplicity in the production of bespoke metal parts.

Print first and then sinter directly

The Studio System 2 offers two-stage processing with a completely updated material library. By using new material compositions, printed parts can be placed directly into the oven, eliminating the usual solvent debinding phase. This results in a virtually hands-free and easy-to-use two-stage process.

Software-controlled workflow

You don't need to be a metallurgy or mechanical engineering expert to create complex metal parts. With our Live Studio software, included in Studio System 2, all aspects of part creation - from printing to sintering - are automated. The software automatically scales your part, aligns it so it can be successfully printed and sintered, generates separable fixtures and applies expert metallurgy to optimize manufacturing. Simply upload your design and follow the integrated user interface for step-by-step guidance.

Simple thanks to intelligent support structures

The Studio System 2 is equipped with the second generation of Desktop Metal's Separable Supports technology. This technology automatically creates seams in the support structures and prints a newly formulated ceramic interface material between the support structure and the part. This allows the parts to be easily and manually removed.

High quality parts

Easily produce parts with complex geometries such as undercuts and internal channels. Live Studio, the central software of the Studio System 2, automates complex metallurgical processes. This produces high-quality parts with a density and feature accuracy similar to that of cast parts.

Reliable order processing

The Studio System 2 is based on data and feedback from thousands of prints and hundreds of customers. It has been designed to ensure outstanding part success and excellent surface finish, enabling users to achieve instant success on a wide range of geometries. This is made possible by a completely redesigned material platform, updated interface technology and new print profiles.

Excellent part properties

A heated build chamber and pressure profiles developed by Desktop Metal ensure an excellent surface finish straight from the oven, while a high-strength gyroid filler now makes the parts lighter. With materials that meet or exceed MPIF standards and the use of high metal volume media, high pressure extrusion and vacuum sintering at temperatures up to 1400°C, the system produces parts with a density of up to 98 percent - similar to castings.

Customizable print settings

With the Studio System 2, you can tailor parts precisely to your requirements. Print parts with walls up to 4 mm thick or fully dense parts (without infill) up to 5.25 mm thick. Adjust the shell thickness to create thicker parts or enable faster processing. Optimize prints for build speed with the standard print head (400µm) or print fine features with the high resolution print head (250µm).

Designed for the office

The Studio System 2 has been designed from the ground up to fit into your team's workflow. With no solvents, no loose metal powder or lasers and very little operator intervention, the system makes it easy to get started printing metal parts - no third-party equipment or specialized facilities required.

User-friendly hardware

With the Studio System 2, you can spend less time managing equipment and more time designing and making parts. Thanks to the user-friendly hardware, print heads can be changed at the touch of a button and materials can be changed quickly with a refillable cartridge system. This allows the user to easily load material during print jobs and safely store excess material. A fully accessible printer and sintering volume and a configurable oven retort ensure maximum flexibility.

No special equipment required

The Studio System 2 features a two-step process that uses no solvents and materials that are easy to store and handle. This makes it ideal for use in office environments - no special equipment or respirators are required. The only requirements are an internet connection, ventilation and a power supply, so you can start printing metal parts quickly.

Significantly reduced user effort

The Studio System 2 helps you take back control of your prototyping pipeline by allowing design and development teams to focus on making the best products possible. The simplified, easy-to-manage process allows users to quickly revise designs, print parts and monitor build progress from their desk. Operator effort is significantly reduced - parts go directly from the printer to the furnace, where a large retort with stackable shelves (10 times more capacity than a similar sized tube furnace) allows batches to be sintered.

Print examples

Use these examples to get an idea of how many parts you can print and at what cost with the Desktop Metal Shop System.

Download

Brochure Desktop Metal Shop System

CONTACT

Our experts will be happy to help you. Get in touch with us!