In an ideal world, 3D printers are no more complex to use than conventional desktop printers. You devote yourself entirely to the part you want to print, send it to the printer and shortly afterwards hold it in your hands.

Of course, we're not quite there yet. And of course the comparison is not entirely fair. 3D printing is a far more complex process, both in the creation and handling of the data and in the printing process itself. But that should not be an excuse not to further optimize and simplify 3D printing processes. Because one thing is clear. For the user, the focus should not be on the printing process, but on the product.

The SLS 3D printing process is the right answer to many questions

SLS 3D printers are an important step towards this ideal world. During the printing process, the parts are surrounded by the printing medium, in the case of SLS a fine powder, until the end. This means that, in contrast to other common 3D printing processes, no support structures are required (overhanging areas do not have to be supported with specially printed structures, which then have to be removed again). In this way, the entire working volume can be used for printing and the entire printing process is greatly simplified. This has a huge impact on productivity and makes SLS technology an increasingly popular competitor to the widely used FDM and SLA 3D printing processes. In the professional sector in particular, it is becoming increasingly clear that SLS 3D printing is the right answer to many questions.

- Works without support structures

- Approx. 10x lower layer thickness compared to FDM 3D printing

- Very complex and even moving parts can be printed

- Wide variety of materials with excellent mechanical properties

- Models can be densely stacked in the build volume, allowing a large number of parts to be printed at once

- The most promising 3D printing technology in many professional fields

The most exciting producer of SLS 3D printers

This is where Sinterit comes into play. The company, based in Krakow, Poland, specializes in the development of advanced and affordable SLS printers. An important feature of Sinterit's devices is that the many freely configurable printing parameters mean that powders from third-party suppliers can also be used with Sinterit devices. A huge advantage for users. If no material with the right properties is available from the printer manufacturer, you can fall back on a third-party supplier. One example is the high-quality and inexpensive SLS powder from the Swiss company ZETH Materials.

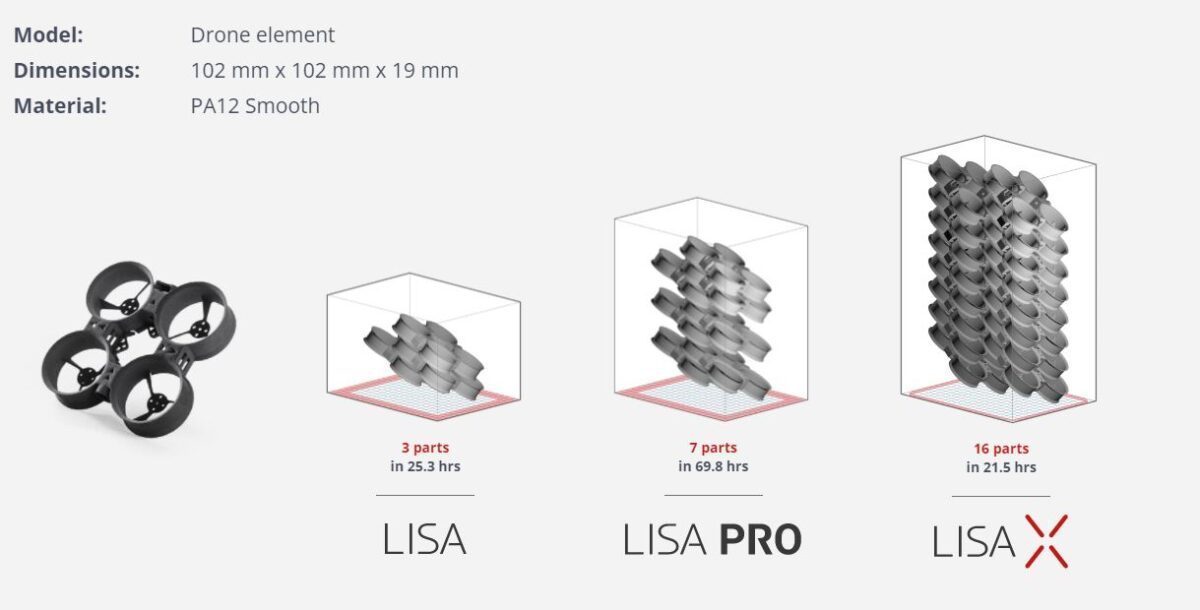

Sinterit's first devices, the Lisa and Lisa Pro, were developed with a focus on a compact form factor and an affordable price compared to the larger and more expensive industrial SLS printing systems of the competition. These printers are particularly popular with small and medium-sized companies, especially in prototyping.

A new generation of SLS 3D printers

Sinterit then presented the NILS 480 at the end of 2021. It is significantly larger and, thanks to the mirror-controlled galvo laser and many automated process steps, also many times faster than the previous models. This device is primarily intended for industrial series production and is therefore also aimed at a completely different target group in terms of price than the Lisa and Lisa Pro models.

So only one thing is missing. A model that is positioned between the beginner-friendly Lisa models and the industrial NILS 480. With a large installation space despite its compact design and the lightning-fast and precise Galvo laser technology of the NILS 480.

The new Sinterit Lisa X...

...offers extremely fast and precise SLS 3D printing, a very large working volume, access to all types of materials and open printing parameters. With a speed of 14mm/h, the entire print volume of 130 x 180 x 330 mm filled with the most complex shapes is printed after 34 hours at the latest. Realistic print jobs are usually completed within 24 hours. Provided that this extreme increase in performance can be used productively, the Lisa X could mean a small revolution in the workflow of many companies.

Who is the new LISA X from Sinterit suitable for?

The main difference between the previous Lisa models from Sinterit is the size of the installation space. The available volume of a Lisa Pro is approx. 75 percent larger than that of the Lisa. So if you want to print very large parts or a large number of small parts in the same pass, then the Lisa Pro is the right choice. If the parts are rather small and are mostly individual parts, the Lisa could be the right device.

A new factor is time. Thanks to its Galvo Laser technology, a Lisa X prints almost 10 times faster than the previous Lisa models. So if you want to print a lot of small parts or very large parts very quickly, then the Lisa X can show off its strengths.

Conclusion

With the Lisa X, Sinterit completes the Lisa SLS 3D printer series. All Lisa models offer the great advantages of Sinterit SLS printer technology: high print quality, excellent material properties, versatile material selection, open print parameters and prints without support structures. All you have to do now is choose the device that best suits your requirements. With a price close to a Lisa Pro and a performance more in line with the NILS 480, the new Lisa X is certainly Sinterit's most exciting product yet.

At CHROMOS Industrial you will find all SLS 3D printers from Sinterit

CONTACT

Do you have any questions about our events?

Contact us!

We will take care of your request as quickly as possible.