ADDITIVE MANUFACTURING - PRACTICAL EXPERIENCE

The use of additive manufacturing (AM) is on the rise in many areas of industry. As Head of Engineering & Design at Swiss Television (SRF), Dieter Schäffler has a unique insight into the opportunities, challenges and benefits of this technology. Here, he shares his experiences and provides insight into SRF's AM journey from its beginnings to current devices and technologies.

Can you tell us how and when your own additive manufacturing journey began?

We started in the department around eight years ago because we realized that there are many applications for us that we can solve perfectly with additive manufacturing.

What kind of printer did you start with and what do you print with now? What are the differences between then and now?

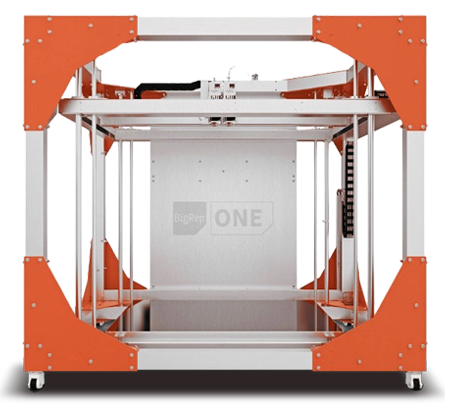

The first device was a Z19 from Makerbot, a semi-professional FDM printer with a comparatively large build space in this price range at the time. In the meantime, our range of equipment has continued to expand. We soon realized that we had a need for larger components and invested in a BigRep ONE. Later, we added SLA devices and FDM printers that can process technical plastics. The devices became more reliable over the years, which is probably mainly due to the constant optimization of the slicing tool.

What new possibilities have opened up for you through the use of 3D printing? Are there also things that have fallen by the wayside?

We have a limited capacity of employees and the production of complex-shaped components with integrated functions would simply take too many working hours if produced conventionally, which are often simply not available. I can run several jobs simultaneously on the 3D printer and have my parts the next day. This saves an incredible amount of time that can be used elsewhere. There have been times when a simple spacer was printed simply because the right raw material was not in stock or no employee had the time. However, it is also very possible to produce demonstration samples and prototypes so that an idea or function can be quickly tested and refined. The possibilities are very diverse and there are virtually no limits. Nothing falls by the wayside. However, it is important to ensure that traditional skills and know-how are not lost, as the best results are often achieved by combining traditional craftsmanship with AM technology.

"WE ARE ABLE TO GIVE OUR 3D PRINTS EVERY CONCEIVABLE FINISH - FROM HIGH-GLOSS VARNISHES AND GOLD PLATING TO IMITATION MARBLE OR NATURAL STONE SURFACES."

- Dieter Schäffler, Head of Technology & Construction at Swiss Television (SRF)

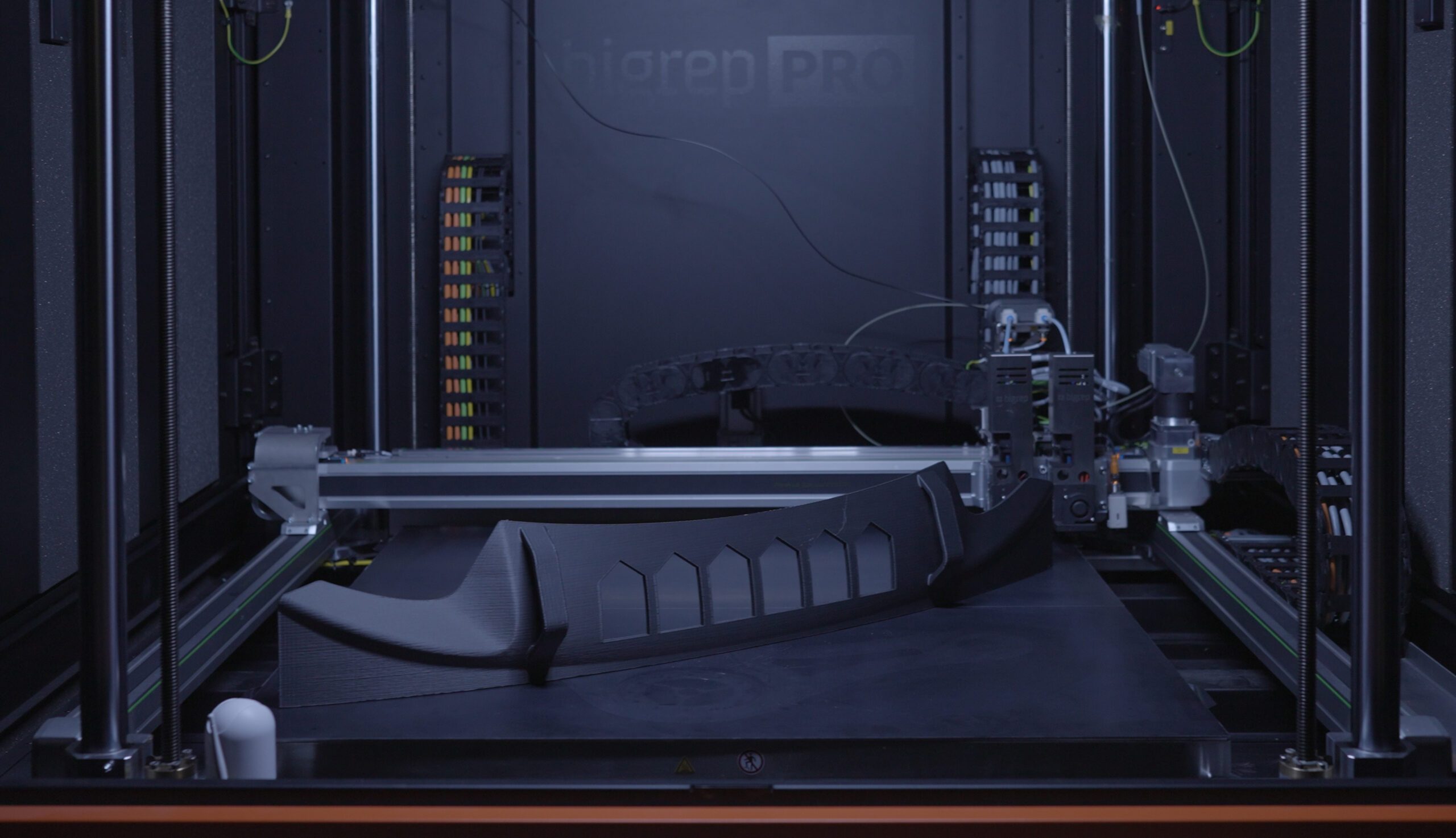

What do you need to pay particular attention to when large-format 3D printing with a printer like the BigRep ONE?

The biggest spoilsport and a particular challenge is the warping of the material. The placement of support material and the choice of print alignment are therefore extremely important and require a great deal of experience. As the large parts often require well over 100 hours of printing time, it is essential to design supports and infills in such a way that valuable printing time can be saved.

If you can only choose one thing at a time: What is the biggest gain and the biggest pain in dealing with 3D printing in your daily work?

Gain: The almost limitless freedom when designing parts.

Pain: Reliability of FDM devices. Clogged nozzles, for example, are always a problem.

You have just been to the FORMNEXT trade fair in Germany. Are there any trends that particularly caught your eye and aroused your interest?

It is impressive what has come onto the market in the AM sector in recent years. With my focus on large part production, it was noticeable that a large number of traditional machine manufacturers have already appeared on the market with their own 3D printing solutions. In comparison, even our BigRep is no longer that big!

It was also exciting for us to see the production possibilities for larger components with a high degree of freedom in surface shaping.

What questions should someone considering entering AM ask themselves?

Why he hasn't done it yet! A little provocative, but in a company where manufacturing, repairs or maintenance is carried out, it simply makes sense! Which process is used and which appliance size is the right one depends heavily on the area of application. It is important to get good advice from a specialist.

DIETER SCHÄFFLER

Dieter Schäffler is Head of Technology & Design at Swiss Radio and Television SRF and has previously worked in this role at TPC AG since 2003. Before his time in show business and further training as an industrial designer, Dieter Schäffler trained as an aircraft technician at Swissair and worked in the aerospace industry.

BigRep ONE

With the BigRep ONE, you get an award-winning large-format FDM 3D printer at an affordable price. With more than 350 systems installed worldwide, it is trusted by designers, innovators and manufacturers. The BigRep ONE is fast and reliable and offers a generous one cubic meter capacity, so you can get your projects done without compromise.

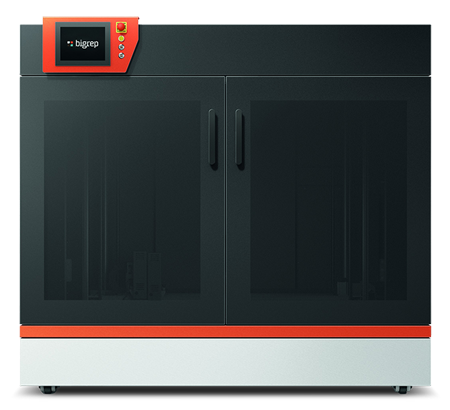

BigRep STUDIO

BigRep STUDIO has been specially developed for reliable use in abrasive and industrial quality materials. Equipped with a fully enclosed housing, a BOFA air filtration system and a temperature-controlled filament chamber, this large-format additive manufacturing system delivers convincing results with advanced materials.

BigRep PRO

With a build volume of 1 cubic meter, the BigRep PRO is a fully enclosed industrial 3D printer for the production of large parts such as functional prototypes, tools, samples and molds as well as end-use parts. Designed for productivity at all stages of manufacturing, it offers a user-friendly, flexible solution to produce faster and more cost-effectively.

Here you will find a detailed feature comparison of the various BigRep 3D printers.