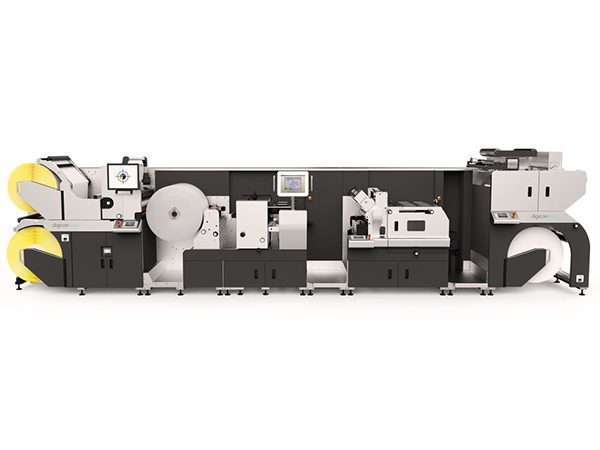

ABG Digilase Series 3

The ABG Digilase Series 3 is the innovative digital print finishing machine for laser die-cutting technology for fast processing with fully automated workflow management.

Get in touch with usSTATE-OF-THE-ART LASER PUNCHING TECHNOLOGY

The Digilase Series 3 is an innovative, digital processing machine with state-of-the-art laser punching technology. Conventional die-cutting tools are not required, saving capital, time, waste, storage space and eliminating the need for heavy manual lifting. It can process both short and long runs quickly, enabling a wide range of label deliveries to be produced on the same day.

With a maximum web width of 330 mm, the basic configuration of the Digilase Series 3 contains everything needed to process a complete job:

- Unwinding module

- 2 x CO₂ sealed laser heads - 200 watts each

- Intuitive, customized workflow management software (fully automated) from Digilase

- Fume cupboard

- Winding module

- Cooling and fume extraction

In addition, a wide range of Digicon Series 3 printing and finishing options are available to generate a real competitive advantage.

INTEGRATION INTO OTHER PROCESSING LINES

As a stand-alone module, the Digilase laser die-cutting unit can be integrated into other digital label processing lines or any other rotary machine.

ADVANTAGES

Simply download the file from prepress and the Digilase Series 3 is ready for production.

The machine does not have to be stopped to switch between the punching work processes; back slitting and longitudinal cutting knives can also be set automatically as an option, so that changeover is possible during operation.

Can punch complicated shapes, fine contours, sharp corners and cuts with pinpoint accuracy and minimal waste.

With optional MIS integration and order data storage with JDF/JMF files.

Punching, engraving, punching and extraction of punching waste.

Production of labels on any material (except PVC and LD-PE); however, it is possible for PE composite films and HD-PE to be punched with very high quality using the laser.

Runs at up to 100 meters per minute, with a continuous cutting mode over a 330 mm web.

The Digilase Series 3 can handle a large number of jobs in a single work process - for example, more than 50 individual jobs can be produced from a roll of 1000 linear meters.

Further information

| Laser beam | 120 micron diameter |

| Laser heads | 2x CO₂ sealed with 200 watts each |

| Maximum web width | 330 mm (13″) |

| Maximum speed | 100 m/min (328 ft/min) |

| Maximum unwinding diameter | 800 mm (31.5 ") |

| Standard unwind shaft | 76 mm (3″) |

| Unlimited shape variations | |

| Large selection of applications | |

| Automatic job change workflow | |

| Suitable for a wide range of materials | |

| Grid winding diameter | 800 mm (31.5″) |

| Maximum winding diameter | 600 mm (23.6″) Optional 800 mm (31.5″) |

| Standard rewind shaft | 76 mm (3″) |

Contact us

Find out more or arrange a demo right away?

Contact us: