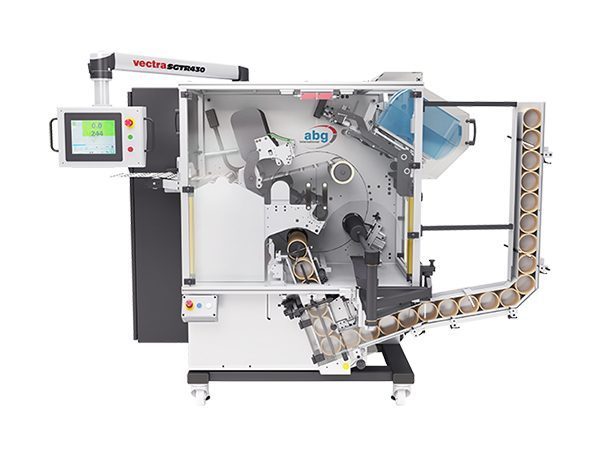

ABG Vectra SGTR wrapping machine AutoSet

The AB Graphic Vectra SGRT AutoSet automatic rewinder is the fully automatic and market-leading rewinder and is also suitable for short runs.

Get in touch with usFULL AUTOMATION

Over the last 20 years, we have driven the development of glue-free wrapping machines and today our Vectra SGTR wrapping machine is unrivaled in the market. With fully automatic changeover, the new AutoSet Vectra SGTR saves hours of costly set-up time. Simply enter the outer core diameter into the system's touchscreen and all mechanical positions are precisely set up - ready for the next job.

The Vectra SGTR attaches the material to the cores at the start of a new roll without stopping or slowing down the machine. In addition, it can be equipped with a label printer and dispenser to seal the finished roll with a label. Heat-sensitive materials are particularly suitable for this winding technique, as there is no need to use hot melt adhesives.

ADVANTAGES

Automatic set-up and changeover means that less training is required.

Runs inline with most presses or converting equipment or offline with a stand-alone unwind/slitter unit.

As no glue is required, there are fewer adjustment problems with the glue formulas - you can also stop the machine during the cutting cycle.

As no adhesive heating module is required.

A space-saving 1000 mm diameter unwinding unit is available for offline operation, with integrated roll lifter, electronic web guiding, adjustable splice table with web clamps and automatically disengageable shear cut unit, complete with five sets of blades.

Enables the automatic and precise positioning of cores on the rewinding shaft, which is equipped with a storage tower or an automatic sorting device for small cores.

Enables the operator to run an Omega processing line and an automatic wrapping machine simultaneously with a single hand-held device.

Further information

| Maximum web width | 330mm (13″) /440mm (17″) /540mm (21″) |

| Maximum speed | 150m/min (492 ft/min) |

| Maximum unwinding diameter | 400mm (16″) |

| Counter | Labels and meters |

| Pneumatic rewinding shafts | 4x 76 mm (3″) as standard |

| Web separator | 6 (5 tracks) |

| HMI | 250mm (10″) touchscreen |

| Automatic ejection of the roll | |

| Adjustable core positioning |

Contact us

Find out more or arrange a demo right away?

Contact us: