Demographic change - changing media usage - digital forms of communication - sophisticated new technologies - these are just some of the keywords that the printing industry has been confronted with for years. High pressure to adapt has become the norm. The four examples below are representative of the ability of an entire industry to meet these challenges. Chromos Printing is proud to be a companion on this journey.

Newly founded

Label Impression SA in Vétroz in the canton of Valais was founded in 2022 by four partners, all of whom come from the printing industry and the world of labels and have been working intensively on the challenges of the local wine market. This has changed significantly in recent years, in particular due to a sharp increase in specific bottlings and a variety of specialities, which means smaller production volumes with a higher degree of individualization.

The founders recognized that the need for high flexibility and fast responsiveness could be ideally met with the possibilities of high-quality digital printing and decided to specialize strongly in the wine label market with their new company. Other markets include the craft sector, breweries and fruit juice producers. Communication and transparency are key concepts for the four founders in order to develop individual solutions for their label customers that combine flexibility, speed, aesthetics and professionalism.

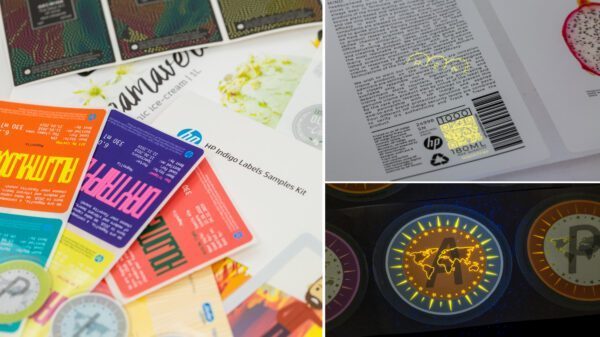

Label Impression SA prints exclusively digitally on an HP Indigo 6K with 7 colors. Among other things, this enables the Pantone color palette and metallic colors to be reproduced faithfully. It is also possible to print opaque white for transparent or solid-colored materials, e.g. on black paper. This digital printing technology is ideal for the selected markets and also allows material waste to be reduced and printing times to be shortened. The system is complemented by two finishing machines that can be used for laminating, hot, cold and blind embossing and screen printing.

It was undoubtedly a great personal challenge for the four partners to embark on the establishment of a new company and become their own boss. After the start-up and six months of learning, the company is technically ready for the 2023 season. The wine label sector is very seasonal, with the grape harvest in the fall and bottling starting the following spring. The confidence expressed so far by wine market players has exceeded expectations and bodes well for Label Impression's operations.

Recalculated

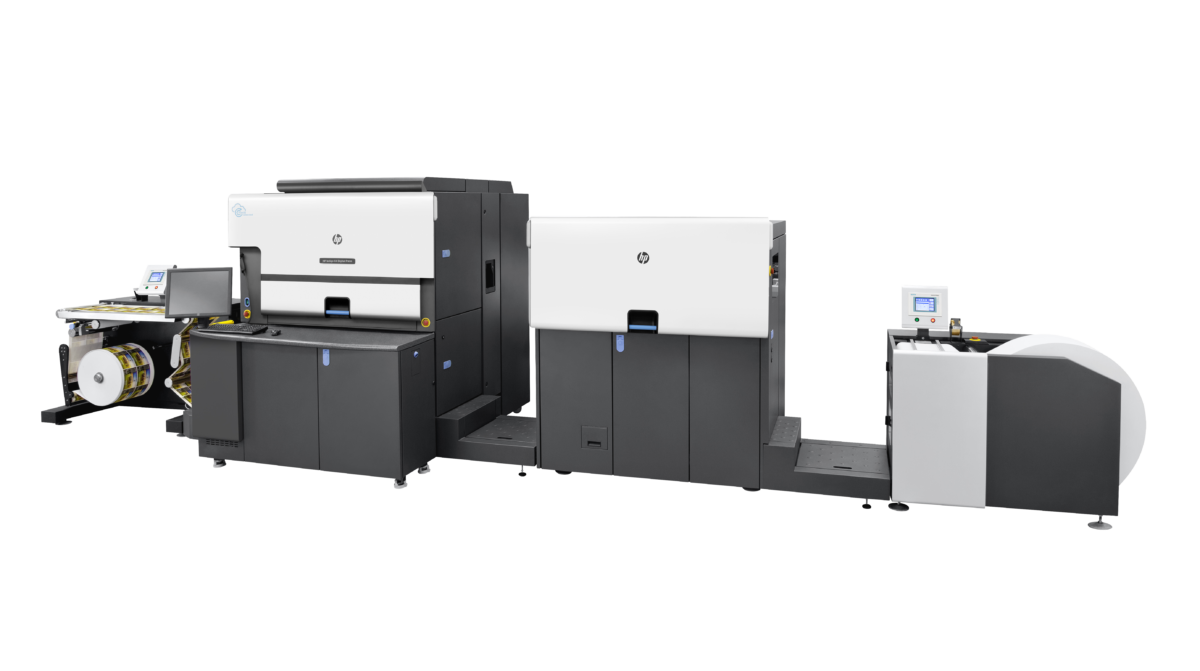

Gutenberg Druck AG from Lachen replaced its 50×70 offset printing press with an HP Indigo 7K digital printing system in January 2022. The company did not opt for an HP Indigo in B2 format, but for a system in A3plus format, and continues to operate a 35×50 offset printing press and two toner printing systems.

Like many other comparable print shops, the question "what next?" was asked before the decision was made. However, the company not only looked at the current situation, but also tried to project existing trends into the future. This included the type and volume of orders, the scope of services, the utilization of existing production resources, the balance between commercial and industrial orders, but also the customer structure and the company's own positioning in the market environment.

This comprehensive projection led to the realization that a 50×70 sheetfed offset press was no longer the right solution. A transparent business analysis of all the figures, taking all processes into account, showed that the chosen solution was best suited to the current and future order structure and could achieve higher profitability. After one year of operation in the new machine park constellation, the figures also show that the decision was the right one.

Although this investment decision should not be seen as a paradigm shift for an entire industry, it is an example of the potential of an open-ended analysis that focuses independently on its own market environment and is combined with a clear vision.

Future secured

Founded in 1908, the Austrian Pirlo Group has developed into a leading national and international manufacturer of metal packaging, exporting its products to over 40 countries worldwide. The Kufstein-based packaging expert offers a wide range of packaging solutions for the chemical/technical, cosmetics, pharmaceutical, food and hazardous goods sectors. Packaging solutions "made by Pirlo" are regularly awarded national and international prizes.

As an established expert in metal packaging, Pirlo further diversified its portfolio in 2010 and entered into the production of laminate tubes. With the founding of Pirlo Tubes, also based in Kufstein, an independent business unit was created. A new era was ushered in with the investment in an HP Indigo 6000 with 7 colors, a coating/laminating machine and two tube converting machines. After an initial learning curve, Pirlo Tubes was able to quickly expand the new market segment and win new customers with customized solutions and further expand existing customer relationships.

Pirlo Tubes has continued to develop positively over the years, meaning that production capacities had to be expanded in regular steps. In this context, Pirlo Tubes has decided to invest in a third converting machine and to replace the HP Indigo 6000 with the latest generation of the HP Indigo 6K with 7 colors at the end of 2022. In addition to higher productivity, the latest technology of the HP Indigo 6K allows the use of new special colors such as Premium White with a higher opacity or silver to simulate a wide range of metallic effects.

Digitally refined

Etivera Verpackungstechnik GmbH in St. Margarethen AT produces and distributes labels and packaging throughout Europe. Self-adhesive labels for the food, cosmetics and non-food industries are produced on several production lines in the 30,000 m2 service center. High-quality finishing techniques play a major role here.

Label printers were open to the opportunities offered by new, digital production processes at an early stage. In order to meet the demand for ever smaller print runs, the proportion of digitally printed labels has risen sharply in recent years, as this enables companies to achieve high quality and productivity even with small print runs. Not only printing, but also a wide variety of finishes such as tactile or haptic effects, hot and cold foil stamping or even spot varnishing can now be implemented using digital technology. Etivera was an early adopter of these digital production options and now combines digital HP Indigo printing technology with digital finishing for maximum productivity throughout the entire production process.

The revolutionary DigiJet module for the Digicon Series 3 from AB Graphics enables Etivera to produce high-quality digital enhancements in a single pass. With combinations of digital foiling, tactile screening and spot varnishing over 225 microns, no finishing requirements remain unfulfilled. Lead times are drastically reduced thanks to waste-free, automated job changes during ongoing operation, the elimination of tool and plate costs and the option of personalization using variable data. The future of digital label production is already a reality at Etivera.