The Swiss site of packaging group Eson Pac AG is now called PEP Labels AG. The start-up now works with the HP Indigo 6900 digital printing press. The conversion to the new machine solution was implemented within two weeks thanks to the active support of Chromos Group AG and opens up new possibilities.

Text: Michaela Geiger / Image: Chromos Group

PEP Labels AG

Duc Quoc Pham, CEO of PEP Labels AG and former Managing Director at Eson Pac AG, has fulfilled a lifelong dream and initially acquired the Swiss branch of the Swedish Eson Pac Group at Pfeffingerring 201 in Aesch BL in a share deal. The management buy-out was completed in September 2019. Since then, structures and processes have been reorganized and made fit for the future.

The new company is called PEP Labels AG and is based on old roots: Paper products were already being manufactured and distributed at the plant in Aesch in the 1970s. Back then under the name Guhl & Scheibler. Shortly before the turn of the millennium, the company merged with a large printing company in Sweden. With another Swedish acquisition in 2011, the company specialized in packaging solutions for the pharmaceutical industry. Now the plant in Aesch is returning to its roots with PEP Labels AG.

"We offer state-of-the-art solutions for the pharmaceutical packaging supply chain," says Duc Quoc Pham in an interview with Pack aktuell. "Among other things, we produce labels for medical packaging at the Aesch site, but also for clinical trials." The company's customers include global players in the pharmaceutical industry.

Covid-19 has set the market in motion. "When it comes to vaccines, everyone wants to be the first on the market," says Duc Quoc Pham. Since 80 percent of the companies involved in this struggle for a solution are also customers of PEP Labels AG, business is booming. "Corona has given us a special boom with labeling for products used in clinical trials," says Duc Quoc Pham. The 50 employees at PEP Labels in Aesch worked in three shifts to meet demand.

In May 2020 - in the middle of the lockdown - the HP Indigo WS 4050, which was already getting on in years, suddenly broke down. "We hadn't planned to replace the machine for another two or three years and now had to reschedule quickly," says Duc Quoc Pham. What he reports matter-of-factly in the interview is an extremely precarious situation for a supplier to the highly structured pharmaceutical industry. Delays in delivery are not welcome. "As a label supplier, we are an integral part of our customers' production processes. You can't just drop out for once."

Quick solution

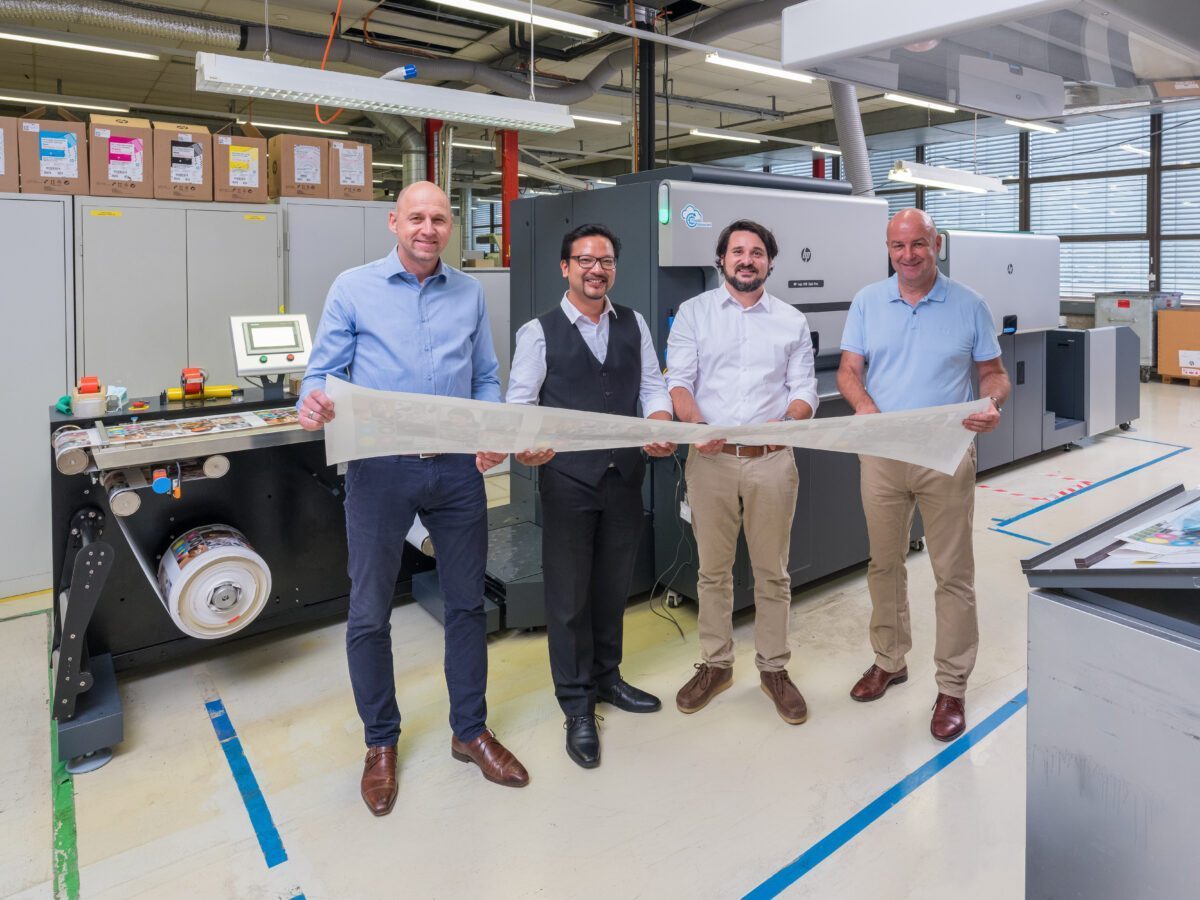

The solution came in the form of active support from Chromos Group AG. The trading company, which operates in Switzerland and Austria and is based in Dielsdorf ZH, is the preferred sales partner for the HP Indigo 6900 digital printing press from HP Indigo. "We have achieved something extraordinary together," says Duc Quoc Pham. From the moment the decision was made to cooperate with the Chromos Group, it took two weeks for the fully functional HP Indigo 6900 digital printing press to be installed at PEP Labels.

"It happened so quickly because we had the HP Indigo 6900 demo machine available at the Chromos Group demo and training center in Glattbrugg. As a demo machine, it was of course fully equipped and leaves nothing to be desired for packaging and label printing," says Markus Konz, Sales Manager HP Indigo Labels & Packaging. The delivery of a completely new machine would also have been possible, but certainly not so quickly. "It usually takes four to five weeks for a machine like this to be installed at the customer's premises and set up for production."

A sensible solution was also found in terms of financing. Given the urgency of the situation, the Chromos Group took over what is normally handled by a bank or the manufacturer and granted a loan.

"Having the right partner at your side in such a challenging situation is worth its weight in gold," says Duc Quoc Pham. "We have definitely found that in the Chromos Group." He has never regretted his decision to purchase the HP Indigo 6900. "From a marketing perspective, we have completely different ways of approaching our customers and presenting new features. Above all, security labels and individualized solutions," says the PEP Labels boss.

New possibilities

The well-equipped demo machine from Glattbrugg already had all the desired features integrated. For example, the HP Indigo 6900 has an inline primer unit (ILP). "This allowed us to integrate a prepress step; the primer station saves us time and gives us a lot of flexibility," says Duc Quoc Pham. Another advantage: the new machine runs twice as fast as the old one. "This means we can serve customers faster at short notice," says the PEP Labels CEO.

By using the new HP Indigo 6900, PEP Labels has already reduced its flexo printing work. "Whereas we previously used four flexo presses to complete 90 to 95 percent of all work on flexo printing, we are now at 80 percent flexo printing and 20 percent HP Indigo digital printing," says Duc Quoc Pham. The aim is to gradually convince other pharmaceutical customers of the advantages of the HP Indigo 6900. Such change projects require a longer time horizon in the well-planned pharmaceutical industry. Duc Quoc Pham is already looking to the future with further strategic considerations. One of the many new applications of the HP Indigo 6900 is microprinting - certain security features that cannot be seen with the naked eye and are therefore forgery-proof. Or QR codes that are printed with invisible ink. "The label will play a very important role in the future," Duc Quoc Pham is convinced. In the pharmaceutical sector and in industry, counterfeit and brand protection for high-quality products is an eminently important issue and is therefore becoming a sales argument for PEP Labels.

The HP Indigo 6900 also requires less preparatory work than previous machine solutions. "This has significantly simplified the workflow for us, as we can simply transfer and enter the customer's number range," says Duc Quoc Pham. From the label to the folding carton, PEP Labels AG is involved in the customer's packaging development processes. Gone are the days when digital printing was only used for short runs. "That's no longer the case today," says Duc Quoc Pham. As the new machine runs twice as fast, many products can be transferred from flexographic printing to digital printing. "It takes the pressure off us in terms of set-up times. This frees up capacity for new projects."