MSD WERTHENSTEIN BIOPHARMA GMBH - NEW WITH ABG OMEGA F150

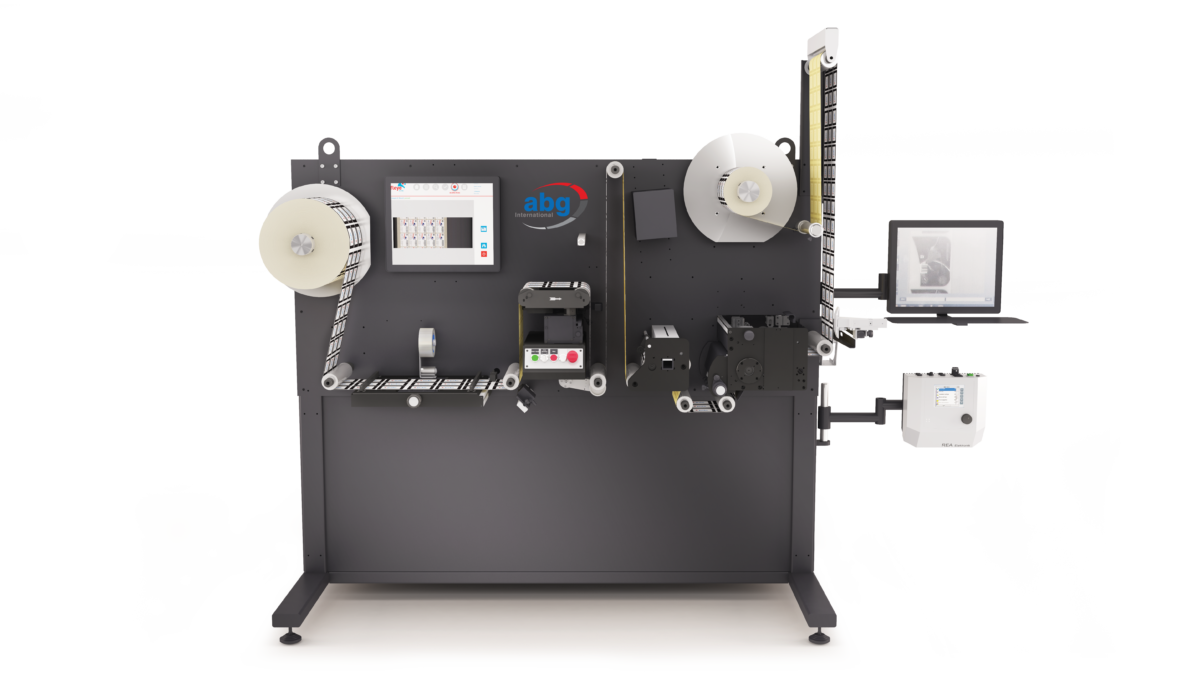

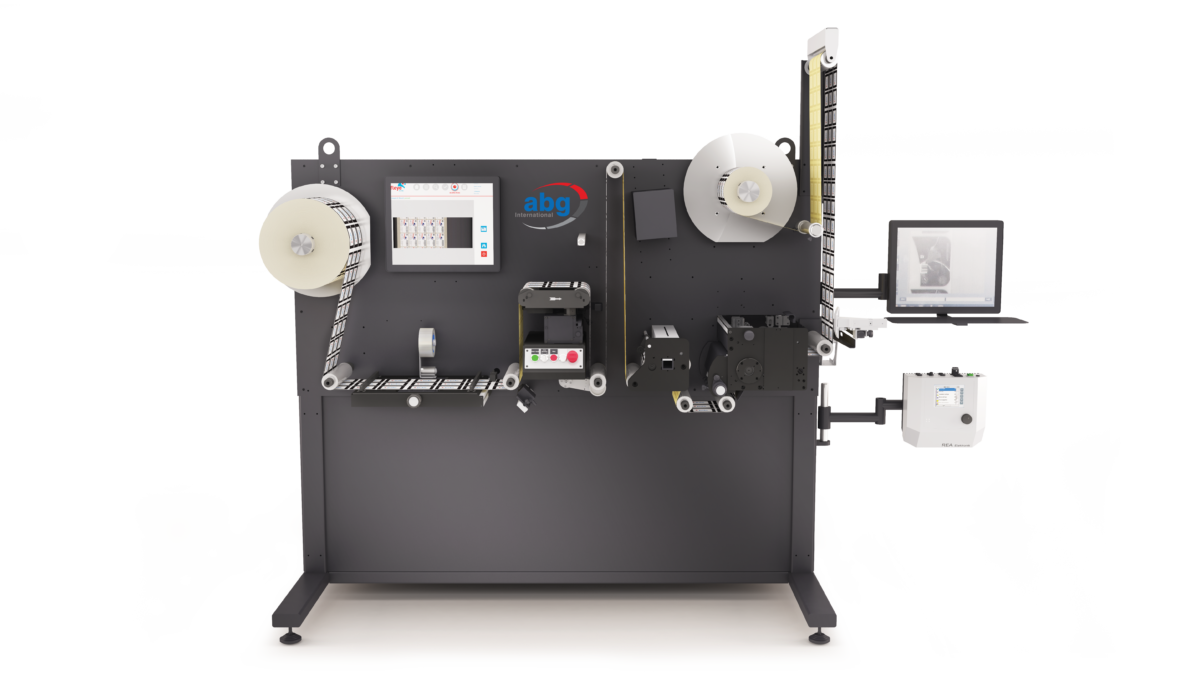

Error-free labels and booklets are a must in the healthcare market. At the pharmaceutical company MSD Werthenstein BioPharma GmbH in Werthenstein (LU), the new Omega F150 inspection and wrapping machine from AB Graphic International has recently taken on this challenging task. The machine uses the high-resolution "fleyeVision" vision system to detect, verify and classify all standard barcodes or characters for the smallest of defects in a fully automated process.

100 percent security in label and booklet printing for highly specialized medical products that are sold all over the world: This is what Werthenstein BioPharma GmbH - a subsidiary of MSD, a leading research-based pharmaceutical company headquartered in Kenilworth, New Jersey (USA) - has been able to offer its customers since fall 2020. The "Omega F150" inspection machine from manufacturer AB Graphic International, which was acquired via the Swiss trading company Chromos Group AG based in Dielsdorf (ZH), reliably detects defects or deviations in the printed image.

Every year, up to two million study drugs are labeled at MSD and sent out in 30 languages to more than 50 countries for clinical trials. The labels and booklets must have an absolutely identical print image and be free of any printing errors - which previously had to be checked manually. This required a lot of manpower, as Stefan Zingg, Associate Director Head Operations Planning at MSD in Werthenstein, explains: "In 2019 alone, we printed over 2.5 million labels for clinical purposes."

From evaluation to current use

While looking for a new inspection machine, Stefan Zingg first met Martin Hürlimann, who is responsible for Label and Converting Systems Sales at Chromos Group AG, in 2015. The Omega F150 was already in focus at the time. The new inspection machine needed to be compact and detect errors or deviations in the print image with absolute reliability. The compact size of the Omega F150 also made it the ideal machine for MSD. This is because space is often limited in research laboratories. And for Stefan Zingg it was also "very valuable that we were able to inspect the Omega F150, which was already in use at another customer. This was an important prerequisite for our evaluation. It gave us a better understanding of what the device can do and what options are available. The customer's feedback was also very helpful for us. With Chromos, we always had a trustworthy partner at our side."

High quality, efficiency and no human error

The aim of MSD and Stefan Zingg was to carry out the inspection of the labels electronically and automatically in future in order to avoid the "human error factor" during these checks. For Zingg, another advantage of the automated process step is that "unlike humans, the machine delivers consistent quality and does not tire, which increases the efficiency of this process step." Specifically, the process involves checking labels printed on one side - so-called single panels or booklets, for example, with the expiry date, patient number or country-specific requirements and information. Each label is checked against the printed image to ensure that all characters have been printed and placed correctly.

Checkable from Chinese characters to barcodes

The inspection of labels with complex characters, such as Chinese, poses a major challenge. This is where the concentration of the label inspector is relevant during manual inspection. The Omega F150 is different: "If a small character or just a line in a character is missing, the machine stops automatically and the faulty label can be replaced immediately. This helps us enormously in terms of time," confirms Lukas Imgruet, Label Document Controller/Designer at MSD in Werthenstein. Another advantage of the Omega F150 for Imgruet is that it can read all barcode variants. "This means that coded patient numbers or country-specific information on the labels can now be checked precisely and compared in the database at lightning speed." What's more, "the machine simultaneously calculates whether all the required labels have been printed".

"Added value is quality, efficiency and flexibility"

For Lukas Imgruet and his team, using the Omega F150 is an "enormous relief, as the hours of manual inspection require a great deal of concentration and errors can be overlooked. A machine, on the other hand, shows no signs of fatigue and guarantees one hundred percent inspection reliability for us."

Stefan Zingg sums up the project with satisfaction: "The main benefit for us is the increase in quality, efficiency and flexibility. On the one hand, we are much faster with the inspections and, on the other, this process requires far less manpower. The Omega F150 is not only very fast, but also very accurate, which gives us great flexibility. A machine that does everything for us, so to speak. The quality of the products is paramount. To achieve this goal, we have received great support from Chromos Group AG."