Flyerline Schweiz AG describes itself as the "leading Swiss online printing company". The company does not disclose detailed figures, but from the outside, one can only conclude: "Something is happening!". Almost five years ago, the decision was made to purchase an HP Indigo 10000 B2 digital printing press, which was later upgraded to the 12000 standard. And now an even more productive HP Indigo 100K is being installed as a replacement - the first in Switzerland. Flyerline Schweiz AG CEO Steffen Tomasi comments dryly: "We need this machine".

Text: Paul Fischer / Picture: Flyerline Schweiz AG

It's a story with Hollywood qualities. One man, Steffen Tomasi, works in marketing for the music industry. He is also responsible for the procurement of printed matter and packaging for the associated value chain. He questions the associated prices and begins to delve deeply into the subject. He realizes that lower costs are possible with the use of gang forms in offset printing. Initially, he worked exclusively with selected printing partners, but in 2002 he founded his own company with one employee. Even then, he was already focusing on the concept of online printing and was way ahead of many of his competitors with this idea.

The company grows and flourishes. Today, 60 specialists work in Altnau, but Steffen Tomasi always remains a pragmatic person despite his visions. In 2016, he sold the majority of the company to the Wipf Group. However, he remained CEO and is still the spiritus rector of Flyerline Schweiz AG to this day. Or as he puts it in conversation with a mischievous smile: "You have to let me do it!"

Innovation

The company's website features the following slogan: "Flyerline means innovation". It states: "As a market leader and printing pioneer, we continuously monitor market conditions and react quickly to trends and needs in order to adapt them to our business model. We don't think in terms of products, but in terms of entire product cycles, thereby creating sustainable innovations that also attract international attention." Big words? Not at all. At Flyerline Schweiz AG, things sometimes happen very quickly, with a high degree of flexibility. A recent example during the Covid-19 pandemic: during the first lockdown, the company spent a six-figure sum to buy up the entire stock of acrylic glass available in Switzerland. As Steffen Tomasi puts it, this made it possible to "actively limit the damage", as entire customer segments at Flyerline Schweiz AG were also severely affected by the restrictions on business activities associated with combating the pandemic. Regardless of such developments: At Flyerline Schweiz AG, innovation does not primarily mean innovation in the procurement of new machines, but innovation for customers. And as mentioned, it is not just about products, but complete product cycles. A good example is the "all-weather lightweight posters" that have been on offer for several years. The concept is based on plastic materials. Flyerline Schweiz AG has thought the concept through from start to finish: they deliver the posters, put them up, but also collect them again and enable them to be recycled.

In addition to innovation and flexibility, Flyerline Schweiz AG also focuses on versatility. There are only a few print shops in Switzerland that are so broadly positioned: Printed matter, packaging, exhibition supplies, furniture made from honeycomb cardboard and, since 2020, coronavirus aids. The company also has a correspondingly broad base in print production: Large-format digital printing, sheet-fed digital printing and sheet-fed offset printing. However, Flyerline Schweiz AG can in no way be compared to "classic" online print shops. Steffen Tomasi: "Our motto is 'small but powerful'. Over 90 percent of our customers are business customers and for 50 percent of orders there is still a direct exchange between us and the customer."

Highlight of a development

Steffen Tomasi says it to anyone who wants to hear it: "I'm not a fan of offset printing". This is, of course, a provocative exaggeration, because it is exactly the same Steffen Tomasi who invested in a high-performance sheetfed offset press from Heidelberg around seven years ago, which reliably "turns" on site in Altnau. And despite everything he says about current and future market developments in the printing markets, he states: "Of course offset printing will always be needed. Offset printing has its justification and there will still be jobs in the future for which only an offset press can be considered." The question that arises in this context is relatively simple to formulate: "How many such jobs will there be at all in the future?".

He states: "The megatrends in printed matter that do not relate to the POS segment or packaging have been clear for some time. On the one hand, the digitalization of communication is reducing the overall need for such printed matter, while at the same time people are generally communicating in a more flexible, short-term and focused manner. Print runs are falling regardless of the overall need for printed matter. People are printing less, but more frequently. We have a number of customers who used to order 10,000 flyers a year from us. Today, they order ten different, customized flyers with a print run of 1,000 per year. The need for individual and personalized printed matter is constantly increasing. This development, which as I said had been foreseeable for some time, has been greatly accelerated by the Covid-19 pandemic. Certain market developments that I perhaps only saw in 2023 or 2024 have "boosted", so to speak, in the last eighteen months. These are of course ideal market developments for digital printing."

Steffen Tomasi and Flyerline Schweiz AG have been relying on sheet-fed digital printing systems for a number of years. They have been involved in the entire technological development in this area. First with sheet-fed toner systems, which were replaced by ever more powerful systems. Then, in 2016, with the HP Indigo 10000 B2 digital press, a new dimension. Steffen Tomasi explains why this leap was made at the time: "We are growing in this segment every year and at some point the productivity of the SRA 3 sheetfed systems was no longer sufficient. We also focused on short-run packaging very early on, and you simply need the larger format to be active in this market at all."

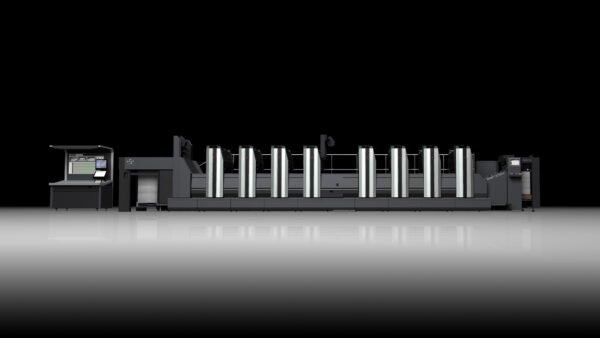

"The Indigo, which we have since upgraded to the 12000 level, was actually still in good shape. A replacement investment for reasons of age was therefore not an issue at all. But in view of the growth in this segment and the market changes we were observing, we needed a machine that was even more powerful. And this is exactly what the HP Indigo 100K fulfills. Based on the same basic technology, this system enables a printing speed that is 30 percent higher than the existing system. Productivity is up to 50 percent higher in comparison."

What's interesting about the whole procurement process is that Steffen Tomasi began evaluating the system in the middle of the pandemic, not before. He explains: "Every crisis is also an opportunity. We also had to deal with the slumps and some of them were severe. But, as I mentioned at the beginning, we were able to cushion a large part of it by quickly adapting to market conditions. I quickly realized how the markets were changing at an even faster pace than before and wanted to be ready for the time after the pandemic to fully meet these market changes. Not only did we invest in the HP Indigo 100K, we also bought a perfect binder and implemented a completely new online store. This all involves considerable investment."

So a forward strategy? "No," says Steffen Tomasi, "I wouldn't call it that. We were well positioned even before these investments. We were doing well both in terms of our business and our product range. But when markets change even faster, you have to react. As I said, without Covid-19, we would have made the investments sooner or later, but the pandemic is fundamentally changing the starting position once again. You have to be ready for the time afterwards and have the appropriate structures in place."

The evaluation began in the fall and the contract was signed at the end of winter 2020/2021. The process was a mix of online meetings, online presentations and a visit to the HP Indigo Experience Center in Barcelona. Sven Bänziger comments: "Of course, the pandemic made the evaluation more difficult, but basically everything went as it always does with projects like this." The new machine was installed in Altnau in summer 2021. In addition to a wide range of commercial products, the machine will also produce packaging (up to 450 microns), stickers and films. And, of course, everything that needs to be personalized and individualized.

What are the main reasons for purchasing the HP Indigo 100K? Steffen Tomasi sums it up: "Significantly higher productivity, greater production reliability thanks to the gripper system and improved color calibration. This is associated with lower unit costs. And we can produce jobs in the rapidly growing packaging segment that were previously not so easy." And the print quality? Steffen Tomasi says: "It's a touch better than the previous model, but to be honest, that wasn't a specific argument for us in the evaluation. The key factor for us was and is the significantly higher productivity".

What's next?

Listening to Steffen Tomasi, you get the impression that it's all sunshine and roses: a healthy company that earns good money and is developing better than the industry average. But that is deceptive. The last eighteen months - shaped by the pandemic - have also caused Steffen Tomasi to worry. There have been permanent structural changes, particularly in the POS segment: "One of our key customers is the food service sector. At times, we lost this completely. But the more the situation improves again due to the pandemic, the more these customers will come back. However, I see a permanent structural change in the trade fair sector. I assume that around 60% of the trade fairs that were held before the pandemic will not return. But here, too, it has to be said that the trade fair sector was already ailing before Covid, and the pandemic has simply significantly accelerated an expected development. On the other hand, we see huge potential in other areas. Packaging, for example. It is becoming increasingly important for SMEs in particular to stand out here. Great products, a super attractive online store and then sending the goods in a no-name box, that somehow doesn't fit together."

And as a "skeptic" of offset printing, how does he see the graphic arts industry developing, especially in Switzerland? Steffen Tomasi: "The winners will be the fast, flexible and innovative ones who are also able to adapt their structures very quickly. We can see from the large European online printing companies that an online presence alone is no guarantee of success in such an environment. With their large production lines and strong focus on B2C, they were too inflexible to be able to react appropriately to the changes. That's why I also believe that SMEs have good prospects because they are very close to their customers. Provided the overall package is right."

And he gives the industry a tip: "We have a broad product portfolio, but even we can't cover everything. I had a similar experience last year. I decided with a major buyer of printed materials that we would no longer offer our services because the cost and income no longer matched. They invited me to a meeting and I explained my reasons. I also explained what we can and cannot do. The response: "Mr. Tomasi, you're the first printer to honestly tell us that you can't do everything. Everyone else always tells us that they can do everything, even though we know for a fact that this is not true." What I'm saying is that customers in the printing industry know exactly what's going on. We need less secrecy and more cooperation and transparency towards customers. You don't have to be able to do everything yourself and should look for partners accordingly and at the same time see where your own strengths and weaknesses lie. For me, this is an important trend for the coming years, alongside the general market changes."