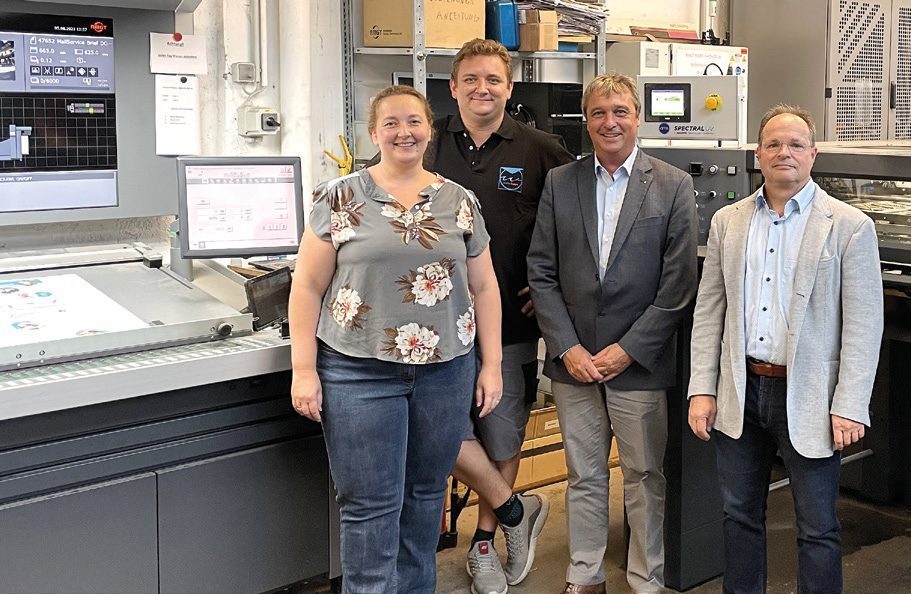

The Graz-based company Winkler Kuvert GmbH has introduced a new formula in the pressroom: An A1 press for the price of a half-sheet press, specifically an RMGT 920, delivers greater efficiency and flexibility.

The name Winkler Kuvert is actually far too short, as the Graz-based company is now a printing company with an associated lettershop. The word Kuvert in the company name is derived from its 70-year history. The company started out as a paper wholesaler, in the 1990s the Winkler family moved into envelope production and at the turn of the millennium the machinery was expanded with a quarter-sheet machine from RMGT/RYOBI. Today, the company positions itself as a full-service provider with a high degree of added value in offset and digital printing, including lettershop.

In addition to envelopes, bags and business stationery, production focuses on all types of mailings with and without personalization and, more recently, increasingly on voucher booklets and flyers. Managing Director Christoph Winkler uses a few figures to break down the production volume handled by the team. A total of 40 million envelopes and bags are produced each year and the mailing production amounts to around 15 million copies. In addition, the company has acquired detailed expertise in mailing and knows the specific regulations in the individual neighboring countries and beyond.

Balanced customer mix at Winkler Kuvert GmbH

The Managing Director's sister, Daniela Wolf, who heads up the customer service department, has identified two trends in the mailing sector: On the one hand, customers have to react ever faster to changes in the market, which also has an impact on the print shop's delivery times; on the other hand, mailings are becoming more and more elaborately equipped, which can be seen, for example, in the choice of paper and the degree of personalization. "We can only respond to the loss of predictability with just-in-time print production."

The company reacted to this development back in 2016 and converted a RGMT half-sheet press from the 7 series to LED-UV drying by Chromos Group AG. "As a result, the sheets arrive at the delivery fully cured and can be turned over for reverse printing, inverted or processed directly." This has enabled us to significantly reduce production times, which our customers appreciate," assures Christoph Winkler. This is not a completely new trend, but it has been reinforced by the coronavirus crisis. Speaking of the crisis, the company has weathered it relatively well thanks to its balanced customer mix, partnership with individual customers and flexibility in production.

The classic A4 eight-pager

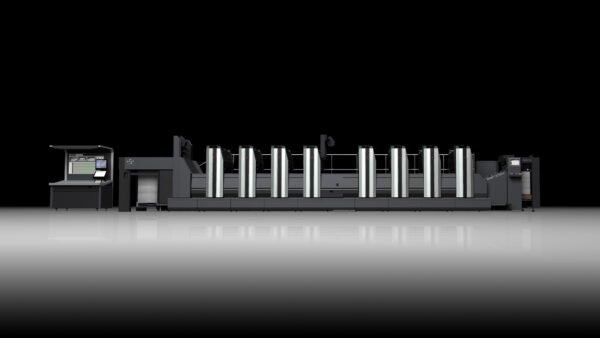

Due to the positive business development, the company took the plunge into A1 format in 2019 by investing in an RMGT 920. The series covers the sheet format of 640 x 920 mm, which corresponds to the classic A4 eight-page format and is very popular worldwide. (There are currently over 1,800 machines from this series in operation in a wide range of configurations from 2 to 8 printing units with and without perfecting). According to a market survey by Chromos Group AG, up to 80 percent of commercial offset presses in the 70 x 100 format are used exclusively to print forms with eight A4 pages. "With the A1 format, we can produce almost all the requests we receive quickly and, above all, efficiently," emphasizes the Managing Director, adding: "and all for the price of a half-sheet press."

Heinrich Maag, who is in charge of sales of the offset printing press at Chromos Group AG, emphasizes at this point that the RMGT 920 represents a space-saving and both cost- and energy-efficient alternative. With the RMGT 920, in the configuration chosen by Winkler Kuvert with five printing units, the automatic plate feeder, the automatic washing device for the blanket and inking roller, the automatic changeover of the sheet guide in the feeder and delivery, the offline measuring station and the LED drying system, the savings potential in terms of acquisition costs is around 35 percent. But there are also significant savings in running costs such as printing plates and electricity consumption, as Christoph Winkler confirmed in an interview with Graphische Revue.

The compact design of RMGT's printing presses has always impressed the company, as space has always been in short supply at the Graz site. However, it also has a positive effect on operability and availability. "After a week, every printer can work on the RGMT 920 without extensive training and the availability of the machine has never been a problem."

LED UV inks: good deinkability given

The topic of LED UV printing inks, which has also been repeatedly discussed in the industry, is now finally no longer an issue. "The questionable photoinitiators have been banned from printing inks and, thanks to further development, deinkability is now good on both coated and uncoated papers." In addition, the Managing Director assures that coating the entire surface of the printed sheets is not an energy-efficient and environmentally friendly solution to speed up throughput times. The immediate curing of the printing inks is also extremely important in connection with hybrid production (offset/digital). "This helps us to optimize the processes in digital printing and further processing."

Summary

The RMGT 920 is the right machine for Winkler's product range, delivering the required efficiency and flexibility. "We have a half-sheet press that enables us to earn money in both quarter-sheet and A1 format, and this flexibility is essential for us in a tough competitive environment. With LED-UV technology, we can offer our customers just-in-time production, which is an absolute must, especially in the mailing sector."

A1 print format an alternative

From our point of view, a printing press in the 920 x 640 mm format range, on which only jobs with eight A4 pages are printed, can certainly be a sensible addition to the existing machinery. Although a second format means a loss of flexibility in machine utilization, the significantly lower investment costs could offset this disadvantage. Companies that commit exclusively to this print format will have to outsource jobs larger than eight A4 pages. Depending on the job structure, this may well be a viable option. But even for companies that have so far worked exclusively in half-sheet format, entering this format class can be lucrative.