CtP systems can be operated for a long time. Many Swiss print shops are using equipment that is 15 years old or more. For the CHROMOS Group, this represents an increasing production risk. We recommend investing in a new generation of reliable and innovative CtP systems, such as those offered by Cron. At the same time, it is possible to switch to processless printing plates without major expense. A current example of this is J. E. Wolfensberger AG from Birmensdorf. swiss print + communication spoke to owner and Managing Director Benni Wolfensberger and Rouven Nagel, Offset Material Sales Print Room, CHROMOS Group.

What were the reasons for the investment in the new CtP system from Cron and the switch to processless Fuji printing plates??

Benni Wolfensberger: We had been using the previous machine, a Screen device, for eight years. At the time, we bought the machine second-hand from a large print shop in French-speaking Switzerland. The CtP imagesetter had been in use for a total of 15 years. The machine worked to our complete satisfaction, but at some point the mechanical problems began to accumulate. More and more parts had to be replaced, and at the same time it became increasingly difficult to obtain spare parts. This meant unplanned technician visits, which were expensive. There were also fewer and fewer potential partner companies with the necessary infrastructure to take over CtP production at short notice in the event of imagesetter failures. Overall, the situation was still reasonably tolerable, but when I realized how often my prepress people were standing around the platesetter with the printers to make sure that the plates were coming out correctly exposed, I knew that now was the time to invest in a replacement.

A clear case for the CHROMOS Group?

Rouven Nagel: We have been a supplier of Fujifilm plates to J. E. Wolfensberger AG for some time now. The screen system was procured through us, but as far as new CtP systems are concerned, we ourselves only offer Cron equipment. So at the beginning of Benni Wolfensberger's deliberations, it was not at all clear whether we would be involved here. However, it is clear that this is a "typical" case: A CtP system that has been in service for many years simply reaches the end of its technical viability after 15 years.

Benni Wolfensberger: At first, I looked around for a second-hand appliance, as we had done the same with the existing system and had had good experiences with it. However, with our specific requirements, it was impossible to find such a system on the market, so in the end I decided to make a new investment. And it was in this situation that the CHROMOS Group came into play.

How did the evaluation process work?

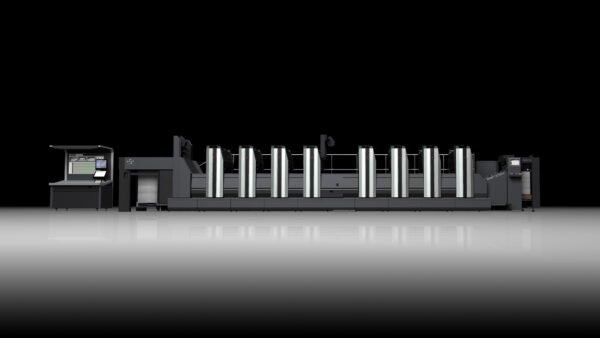

Benni Wolfensberger: We looked at all the possible solutions on the market. There aren't that many in the 70 × 100 segment. Two points were important to us: we wanted automatic operation with five different plate formats and a partner who could supply everything from a single source. At the same time, we wanted to install the new CtP system close to the pressroom. That narrowed down the choice even further. When Rouven Nagel explained the advantages of the Cron systems to me, I was a little skeptical at first. A CtP system "Made in China"? But it quickly became clear during the evaluation that only Cron was in a position to supply a CtP platesetter that could work automatically with five plate cassettes and whose external dimensions would fit into the space provided. The competitors' systems were much larger in terms of space requirements for the required configuration.

Rouven Nagel: This is our clear message: Cron's CtP systems are the best and most reliable systems in the world in terms of technology. And the most innovative. Cron has been the global market leader for a long time and we have sold and installed around 40 systems in Switzerland. However, as many CtP users in Switzerland, especially those with older systems, have not been aware of what is happening in the CtP market for some time, they are often quite surprised when they are offered a Chinese product. There is often mistrust at the beginning of the evaluation. Benni Wolfensberger was also very skeptical at the beginning and we had to convince him first.

Benni Wolfensberger: It's true, I was quite skeptical at the beginning. But the available facts quickly convinced me to take a very close look at this system during the evaluation. Cron was the only provider able to meet our requirements 100%. But that wasn't enough for me. You can talk and make a lot of promises. That's why I wanted to know from reference customers what experiences they had had with the Cron systems. After these discussions, I was confident that I was making the right investment decision. But I calculated and evaluated right to the end. In the end, the cron solution was simply the best!

Technically the best solution and the best value for money?

Benni Wolfensberger: No, in terms of price, all the offers were close together. And with certain manufacturers, I could have had the systems together with an attractive printing plate contract, but I didn't want that. First and foremost, I wanted a CtP system that would perform reliably like its predecessor. The technology offered by Cron simply seemed the most convincing to me. And in terms of price, you can summarize it like this: Cron's solution wasn't the cheapest, but it offers the most added value.

Rouven Nagel: I can endorse Benni Wolfenberger's statements. Cron is not a "low-cost provider". They don't want to establish themselves on the market with the cheapest CtP systems, but with the best technology. Today, Cron is probably the only manufacturer of CtP systems for which the development and construction of such systems is the absolute core business. In my opinion, this is the difference between Cron and the other remaining competitors. That sounds a bit harsh, but for these suppliers, the development and construction of CtP systems has been a "side business" for a long time. Accordingly, less effort is put into the further development of these systems than with Cron.

What is the difference between Cron and other providers?

Rouven Nagel: First of all, there is the philosophy of "everything from a single source". Cron not only builds and develops the CtP systems itself, but also the matching automation devices. These are not purchased from external suppliers. This enables the company to offer complete configurations that are significantly more compact than those of all competitors, especially in terms of length. Another major advantage is the use of single diode technology for exposure. Today, competitors rely on the supposedly faster GLV heads, but if a diode breaks, the entire head has to be replaced. Cron, on the other hand, has designed its entire system mechanically in such a way that production times are practically identical to those of the competition. And Cron relies on "heavy metal" in the truest sense of the word. In our opinion, stability and processing quality are simply the best that is available on the CtP system market today. All this means that the systems are practically fail-safe.

Can you confirm this statement, Mr. Wolfensberger?

Benni Wolfensberger: Yes, I can confirm that. The system was delivered to us in June and we went into full production after two days. No teething problems, no teething troubles, simply nothing. So far, all our experiences have been exceeded. The system was installed in a closed room next to the printing presses and produces absolutely reliably with its five format cassettes. To be honest, based on our experience and that of others, I can't say what it will look like in ten years' time, but when I look at the overall design, there shouldn't really be any surprises!

Rouven Nagel: We now manage 40 systems in Switzerland, and the maintenance costs are in line with our forecast at

. With our partner Thomas Früh from GP Systems, we more than cover the service requirements of the installed base. We also have enough spare parts in stock in Dielsdorf so that we can support our customers in Switzerland independently of the parent plant in China.

Together with the Cron system, the company has switched to processless Fujifilm Superia ZD printing plates. What is the background to this?

Rouven Nagel: The focus of this investment was clearly on a new system that would produce automatically with five format cassettes. Which printing plate would be used was not an issue. I then suggested to Benni Wolfensberger that he switch to our Fujifilm processless printing plates.

Benni Wolfensberger: We have a six-color 70 × 100 sheetfed offset press in LED configuration in the pressroom. We use thermal plates accordingly. When Rouven Nagel approached me about the possibility of switching to processless plates, I was initially quite skeptical. However, tests then showed that it was feasible. So we decided to make the switch. I am still amazed that we were able to make the switch with virtually no major changes or impact on our new CtP system and LED UV press. It's another important added value that we can register with the switch to the Cron Ctp platesetter. To be honest, however, this was never the focus.

(Interview and images: swiss print + communication October 2023, Paul Fischer)

Contact us

Do you also have a need for renewal in the CtP sector? Our experts will be happy to help you. Please contact us.